Lafayette Rapid Prototyping Lab Manual

Installation

First you should download the latest version of Lafayette Rapid Prototyping Lab from our homepage at https://www.repetier-server.com.

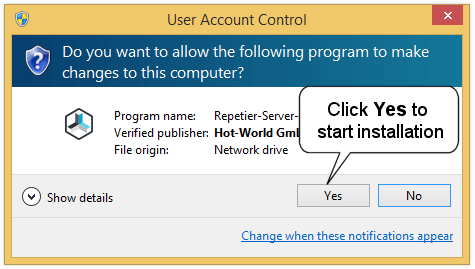

- Open the downloaded installer.

-

Click on Yes to start installation.

![]()

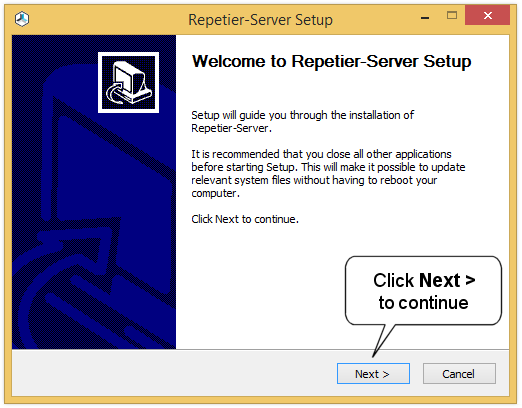

-

Click Next > to continue.

![]()

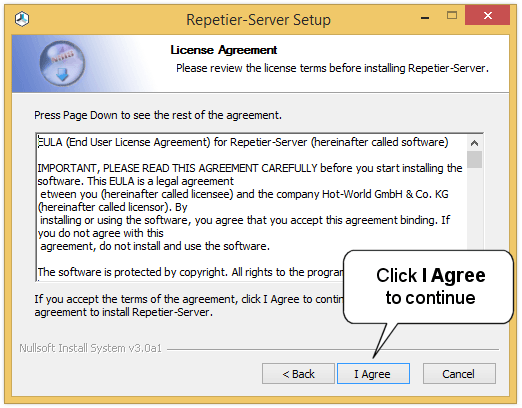

-

Click I Agree to agree to our licence agreement and to continue.

![]()

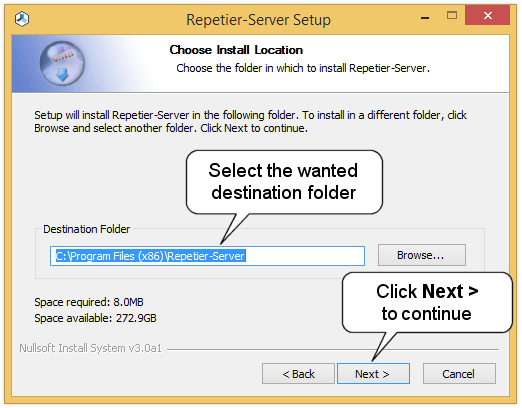

-

Select the destination folder and click Next > to continue.

![]()

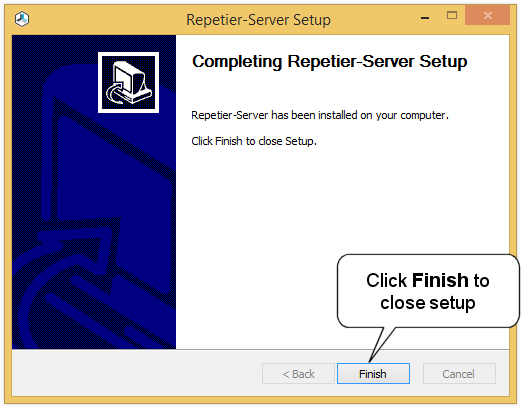

-

Click Finish to close setup.

![]()

-

Lafayette Rapid Prototyping Lab starts automatically a new browser window.

The local URL is: http://localhost:3344

Important

Data Storage

By default the server stores all data in a global directory, which is normally located at C:\ProgramData\Repetier-Server\. This directory gets never deleted by updating or uninstalling the server to prevent data loss. If you want to back up your current state, just backup this directory.

Start and Stop Lafayette Rapid Prototyping Lab

The Server works as a background service. For this reason, you will never see it in the list of running programs, and you never start it directly. It will be started automatically at startup of windows, so you can access it any time with your browser.

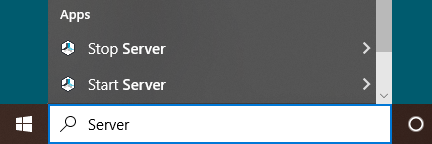

To start and stop Lafayette Rapid Prototyping Lab, just enter Start Server or Stop

Server in the Windows start menu. A small app will start or stop the server.

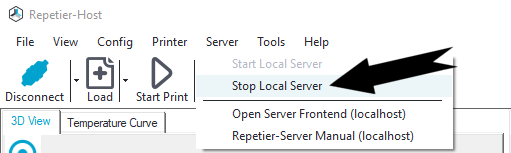

TYou can do this also in Repetier-Host:

Alternatively, you can follow these steps:

- Right click on the Windows Taskbar and start Task Manager.

- Click the tab Services.

- Right click on RepetierServer and select start, stop or restart. That's all.

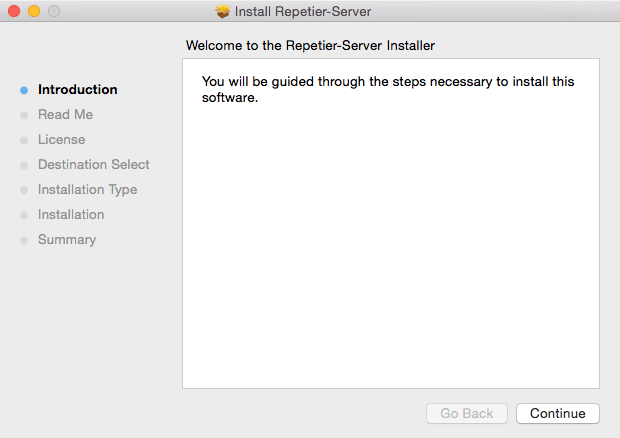

- Open the downloaded file.

![]()

- Click Continue to skip introduction

page.

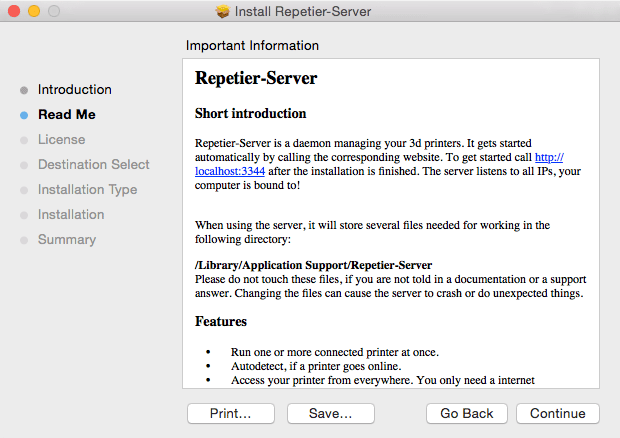

![]()

- You get a read me with short introduction, click on

Continue.

![]()

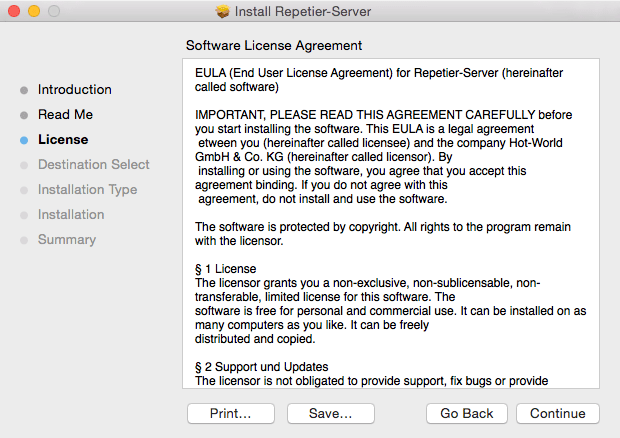

- You see the EULA, click

Continue.

![]()

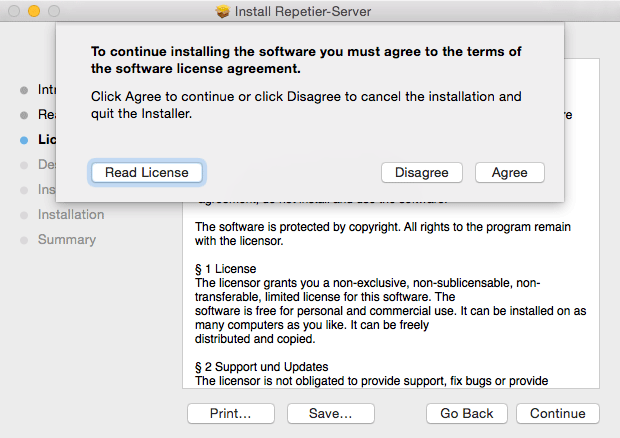

- Click Agree to continue.

![]()

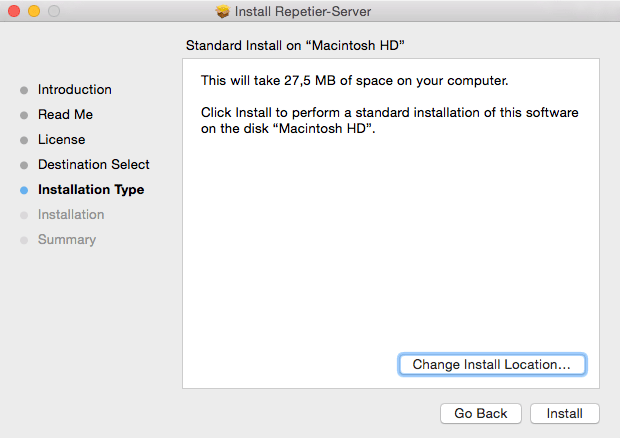

- Choose the installation location and click

Install.

![]()

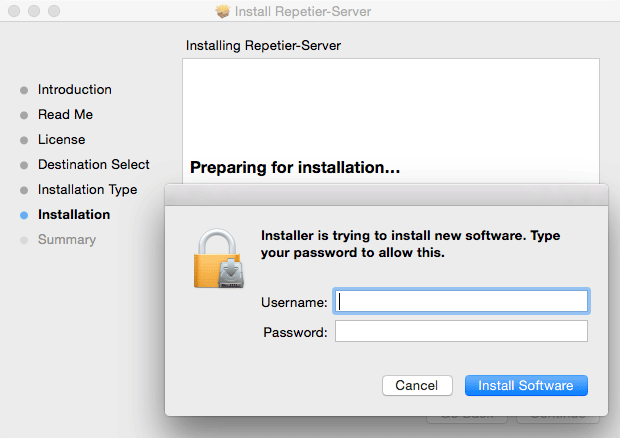

- Enter your username and password to allow installation and click Install

Software.

![]()

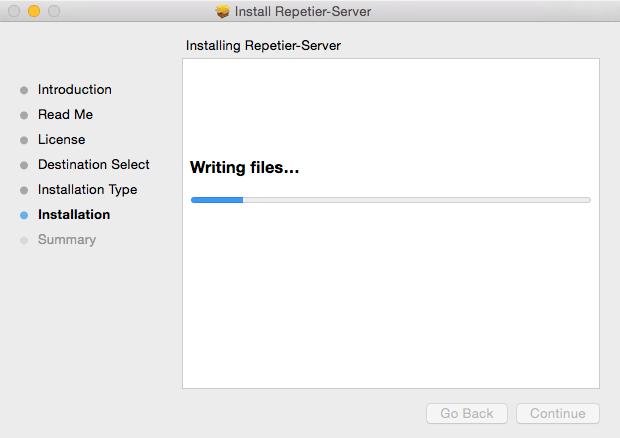

- Wait a while for the installation to

finish.

![]()

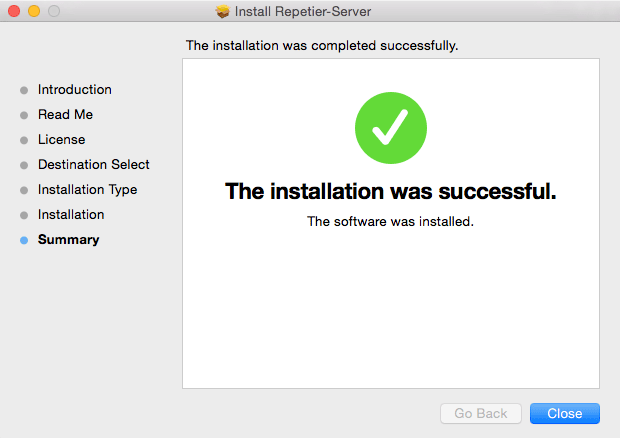

- Click Close to finish

installation.

![]()

Important

Data Storage

By default the server stores all data in a global directory, which is normally located at /Library/Application Support/Repetier-Server/. This directory gets never deleted by updating or uninstalling the server to prevent data loss. If you want to back up your current state, just backup this directory.

Start and Stop Lafayette Rapid Prototyping Lab

The server works as a background daemon. For this reason, you will never see it in the list of running programs, and you never start it directly. It will be started automatically start with the first initiated connection with your browser. To start and stop it manually, open a terminal windows and enter

# Stop server

sudo launchctl unload /Library/LaunchDaemons/com.repetier-server.RepetierServer.plist

# Start server

sudo launchctl load /Library/LaunchDaemons/com.repetier-server.RepetierServer.plist

Uninstalling Lafayette Rapid Prototyping Lab

To uninstall Lafayette Rapid Prototyping Lab, please open your terminal and enter:

/usr/local/Repetier-Server/bin/fulluninstall.shTo install a new version of Lafayette Rapid Prototyping Lab download the version matching your computer and open a terminal and go to the download directory. There you enter:

sudo dpkg -i NewRepetierServerVersion.debAfter this, the server should already be running, and you can access the interface with http://localhost:3344 or http://<ip address>:3344 if you are running it on a remote linux computer.

Important

Data Storage

By default the server stores all data in a global directory, which is normally located at /var/lib/Repetier-Server/. This directory gets never deleted by updating or uninstalling the server to prevent data loss. If you want to back up your current state, just backup this directory.

Start, Stop and Restart Lafayette Rapid Prototyping Lab

The Server works as a background daemon. It will be started automatically at startup of linux, so you can access it any time with your browser. To start, stop or restart it, enter the following command in a terminal:

# Start server

sudo service RepetierServer start

sudo /etc/init.d/RepetierServer start

# Stop server

sudo service RepetierServer stop

sudo /etc/init.d/RepetierServer stop

# Restart server

sudo service RepetierServer stop

sudo /etc/init.d/RepetierServer restart

In newer systems with systemd init configuration, you need to use the service command. The init.d version only works on older systems!

Configuration

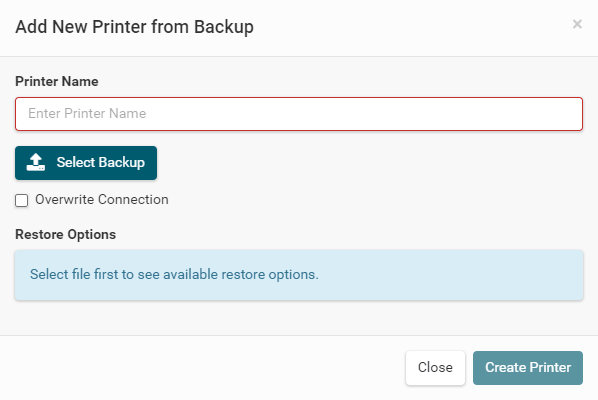

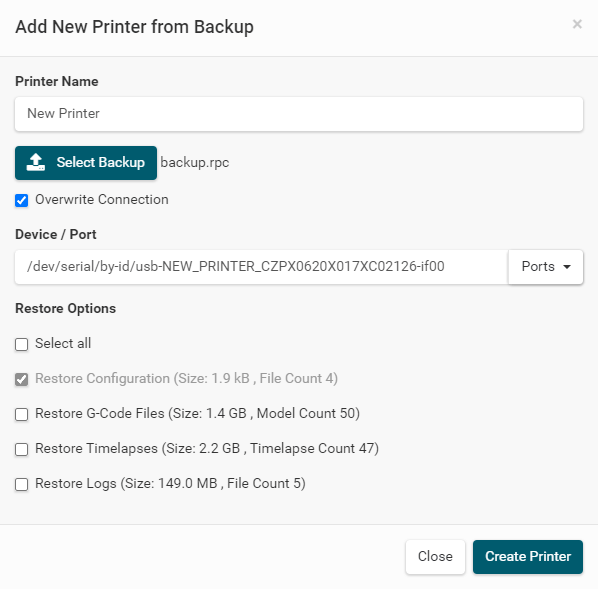

Upload Backup File

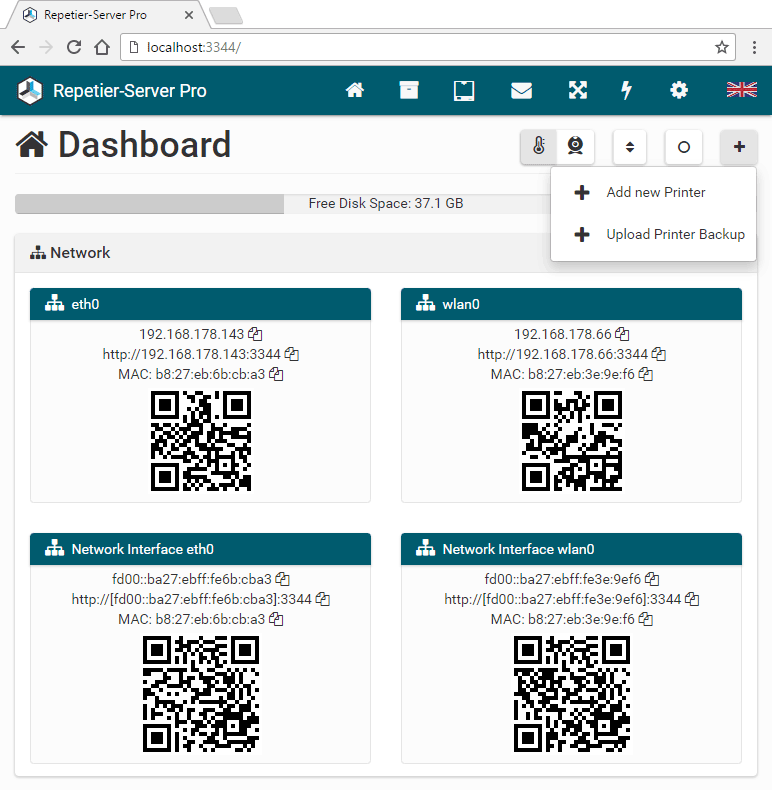

The easiest way to set up a new printer is to upload an existing backup file. Go to

and click on Upload Printer

Backup. Enter a printer name, select the backup file.

Select Overwrite Connection to select a device / port. Then select

the restore options, if you just want to restore the Configuration or g-codes files, timelapses and Logs.

Then click Create Printer. That's all.

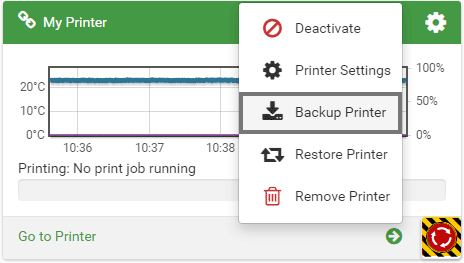

To create a backup file, go to and click

Backup Printer in the printer

overview.

Configuration Wizard

Another very simple way to add a new printer is our Configuration Wizard. Go to and click on + Add new Printer.

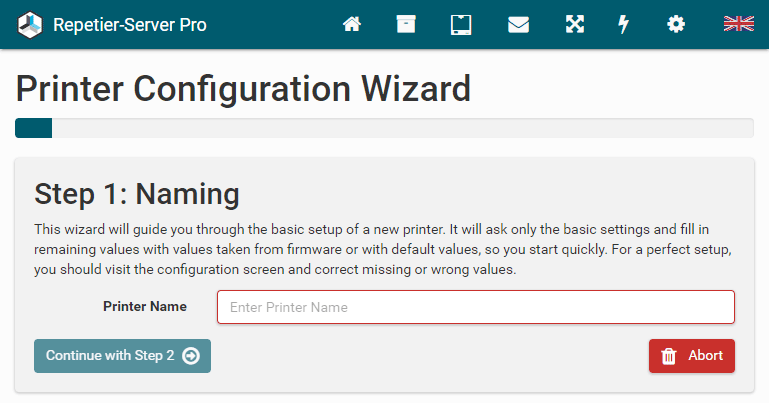

-

Step 1: Naming

In the first step you just have to enter the printer name and click Continue with Step 2 .

![]()

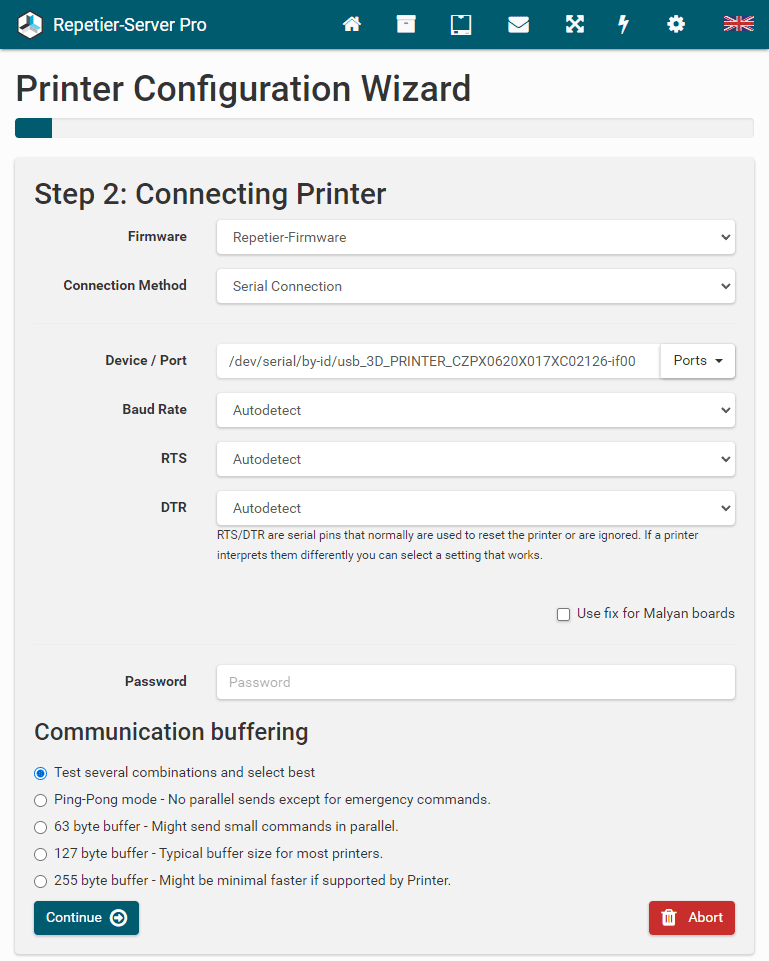

-

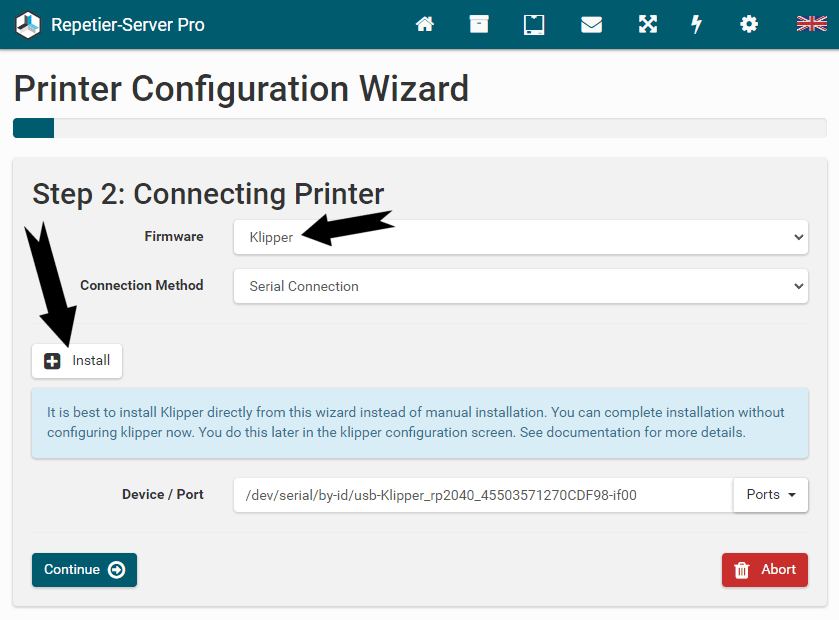

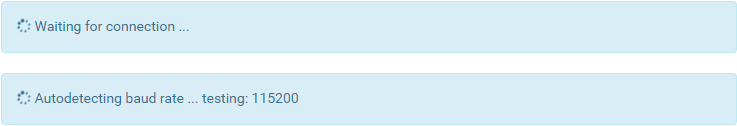

Step 2: Connecting printer

Here you have to select, which firmware is used (Marlin, Repetier-Firmware, RepRapFirmware, Smoothieware), you have to set the Connection Method (Serial Connection, Pipe/UNIX Socket, TCP/IP Connection) and the matching parameter. For the serial connection the baud rate can be set to autodetect, which will test the typical rates. In case autodetect fails, you have to set it yourself.

To speed up communication, the server sends as many commands as possible in a row. To prevent data loss, it is essential to know how many bytes the firmware can store, before the firmware buffer overflows. All known firmwares support at least 63 bytes. Firmwares normally support 127 bytes. If you see a lot of resend requests in the log while printing, the value is too high.

Click Continue to connect the printer.![]()

The configuration wizard now tries to read as many data as possible from the firmware. Whatever it detects gets set to the detected values. In the following pages detected values are marked with green circles.

![]()

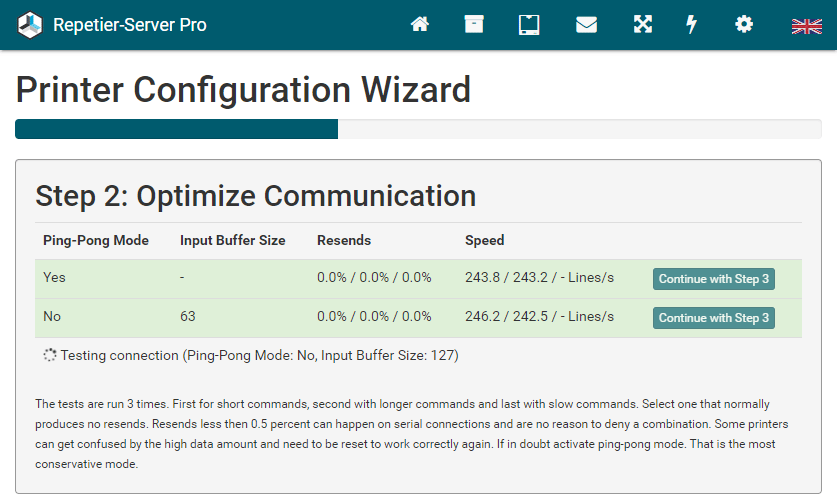

Then the configuration wizard tries to find the optimized communication and tests ping-pong mode and different input buffer sizes. The tests are run 3 times. First for short commands, second with longer commands and last with slow commands. Select one that normally produces no resends.![]()

-

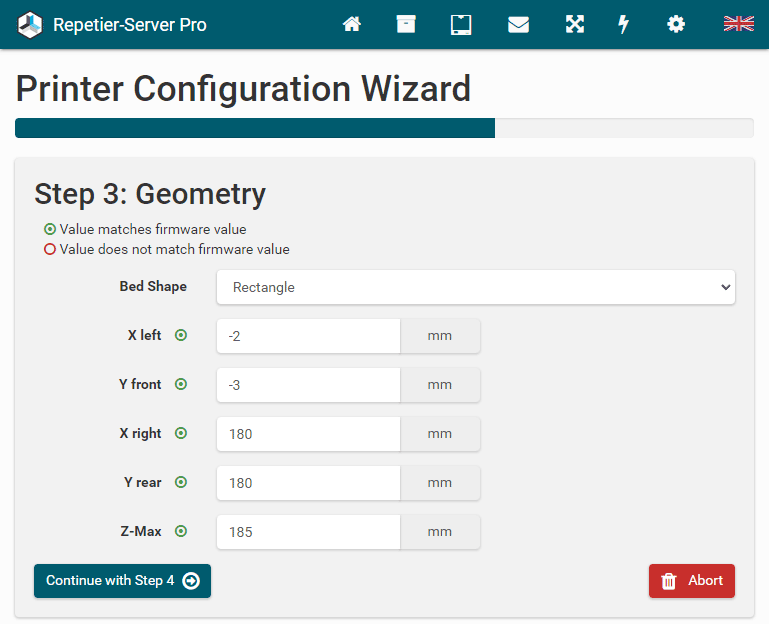

Step 3: Geometry

Here you can set the dimensions and bed shape of your printer. Then click Continue with Step 4 .

![]()

-

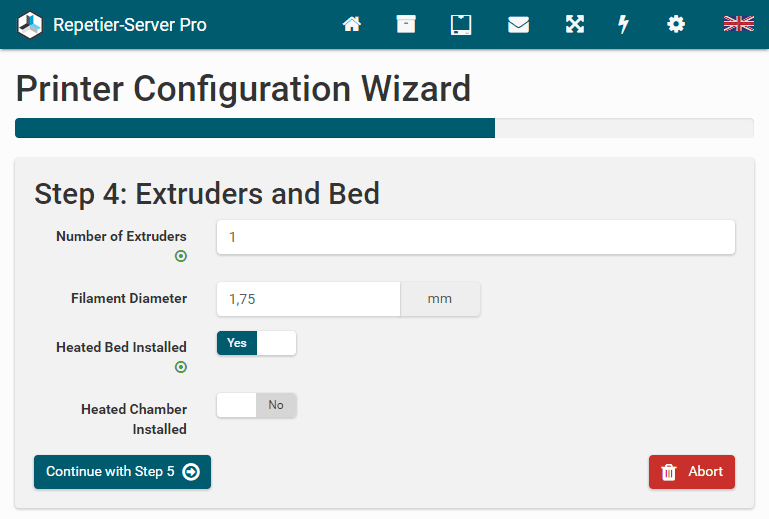

Step 4: Extruders and bed

Set the number of extruders and the filament diameter. Typical filament diameters are 1,75 mm and 2,85 mm. Then click Continue with Step 5 .

![]()

-

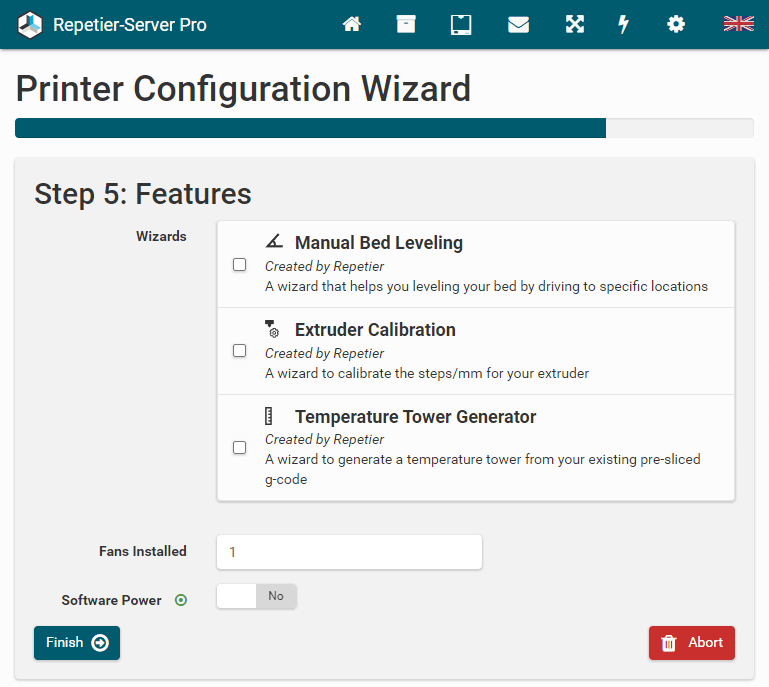

Step 5: Features

Here you can select and install some of our wizards and check, if you have installed fans and if you can enable main power with software command. Then click Finish Wizard . That's all. Now the most important values are set, and you should be able to use the printer already. To get most out of your printer, you should visit the printer settings and fine tune the remaining values, e.g. for better time prediction and easier use.![]()

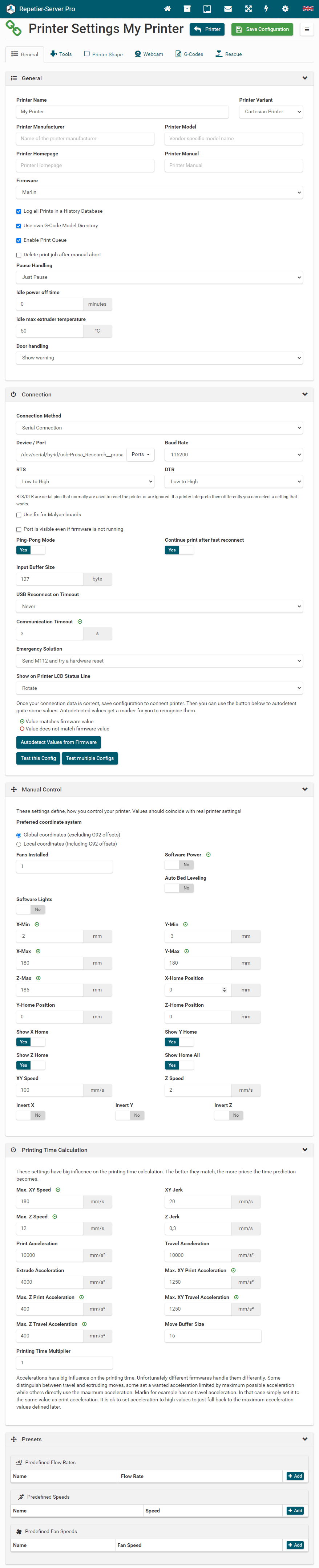

Printer Settings

Select your printer on the dashboard and go to Printer Settings.Here you can set all printer related parameter. So it is a good idea, to check these settings once your printer works. The settings are split into several categories to make navigation easier. To save the changed settings, press Save Configuration. If you leave settings without saving, you will get a security question to prevent accidental data loss. For parameters which may be difficult to understand you get a popover with detailed information when you click on the text field.

Here you find a manual how to set up a webcam for Windows, Linux and Mac.

Show a Printer LCD Status Line

Show a Printer LCD Status Line

If your printer has an LCD, you can select what will be shown in the status line (Do not set status, Show ETA, Show ETE, Show Layer, Rotate).

Continue print after fast reconnect

This function can be a real print saver if it works and is therefore enabled by default. To understand this you need to know that the os can disconnect th connection to the printer. This happens e.g. if in usb a back emf is registered or if the voltage drops too much. This causes of course the printer to disconnect, and the print gets aborted. Now with this option enabled Lafayette Rapid Prototyping Lab will try to quickly reconnect without resetting the printer. If this succeeds within 10 seconds, it will continue with the print like nothing happened. There are only 2 reasons why you would want to disable this function. Reason one is you only accept very perfect objects and just the chance of a blob where it paused a few seconds makes you crazy. Reason two is that it does not work, and it is not possible to reconnect without problems. Unfortunately this can happen. Reason for this is that the os must toggle RTS/DTR signal on open, which often causes the board to reset and then positions etc. are lost and continuing is dangerous. Nonetheless, it seems that not all drivers on all systems do this or toggle there is too fast to cause the reset. On Windows the DTR state must end with low to make the feature work.

USB Reconnect on Timeout

This function is only available for linux systems. It is meant to solve another problem some printers have. It can happen that the communication is still open, but you suddenly won't receive any data from the firmware. Our tests have shown that unplugging usb cable helps in this case to restart communication. Now we learned how to simulate this replugging and when you don't get any answer for a longer time than expected, you can simulate to reconnect which reinitialise the driver, so it hopefully works again. You will see the printer disconnect and reconnect afterwards. In case a print was already running it should continue to print if this does not reset the printer, which we try to prevent, but success depends on the driver implementation. Some still reset the printer while others don't. The early selection will reconnect a few seconds after first timeout if no response was received while the conservative solution waits for the second timeout.

Fix missing ack before slow commands / Fix exceeding ack on timeouts

When ping-pong is disabled, Lafayette Rapid Prototyping Lab will try to send multiple commands in parallel to improve the communication speed. This works great as long as we see all acknowledgements from printer firmware (ok). Now if we miss one due to communication errors or a command takes longer as expected and we time out that command sending next commands the internal bookkeeping is wrong. This causes for a missed ack in best case a slowdown and in the worst case a timeout. The option Fix missing ack before slow commands adds a small communication test before sending a slow command to check if we are in sync. It can detect up to 2 missing acks. If we miss more, we will get a timeout. The option Fix exceeding ack on timeouts will try to detect if we have more acks than expected and will remove them. This can happen if we did not miss an ack, but the command needed longer than expected, and we got the ack after the command finishes also it was assumed we missed it. So this option fixes this and also better handles timeouts due to unexpected longer commands. When you use USB Reconnect on Timeout using this makes no sense, since you reconnect printer anyway on timeout.

In ping-pong mode these options are disabled and invisible in the configuration.

Idle power off time

You can call the event dependent g-code script "Shutdown printer" when the printer is the set time idle and the extruder temperature is already below the set threshold in "Idle max temperature" field. If the time is 0 this feature is disabled. Also, this is named power of it actually does nothing in standard configuration. It is just, that this is the typical intention, but there is not one solution to power of a printer. Most can not do it at all, so solutions are to use a wifi controlled plug instead in most cases. And these have all different solutions and required parameter. So we give you a script where you can add what works.

Note: Never just power off the pc running Repetier-Server. Always shut down the os cleanly to not damage the hard disk. and corrupt the filesystem.

Presets

You can set these values manually when printing, but you often have default values that you can set here so that you can select them directly.

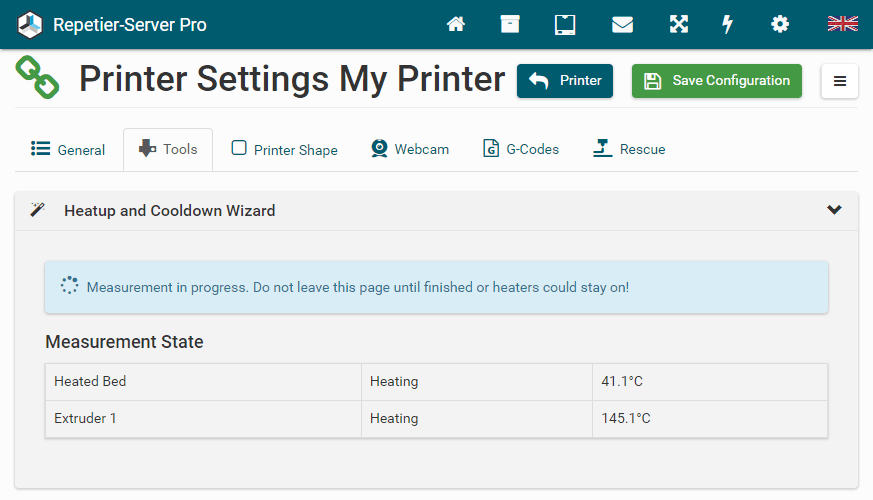

Heatup and Cooldown Wizard

To calculate exact printing times, you should run the Heatup and Cooldown Wizard. This feature measures heating and cooling speed needed for accurate printing time prediction.

- Go to your printer on the dashboard and click

Printer Settings

Tools and click

Start

Wizard.

![]()

- Make sure your printer has power! Then enter typical temperatures for extruders and beds, then click

Start

Measurement.

![]()

- Now you have to wait. The wizard tracks the warming and cooling speeds, which will take some time,

especially

the cooling of the bed is time

intensive.

![]()

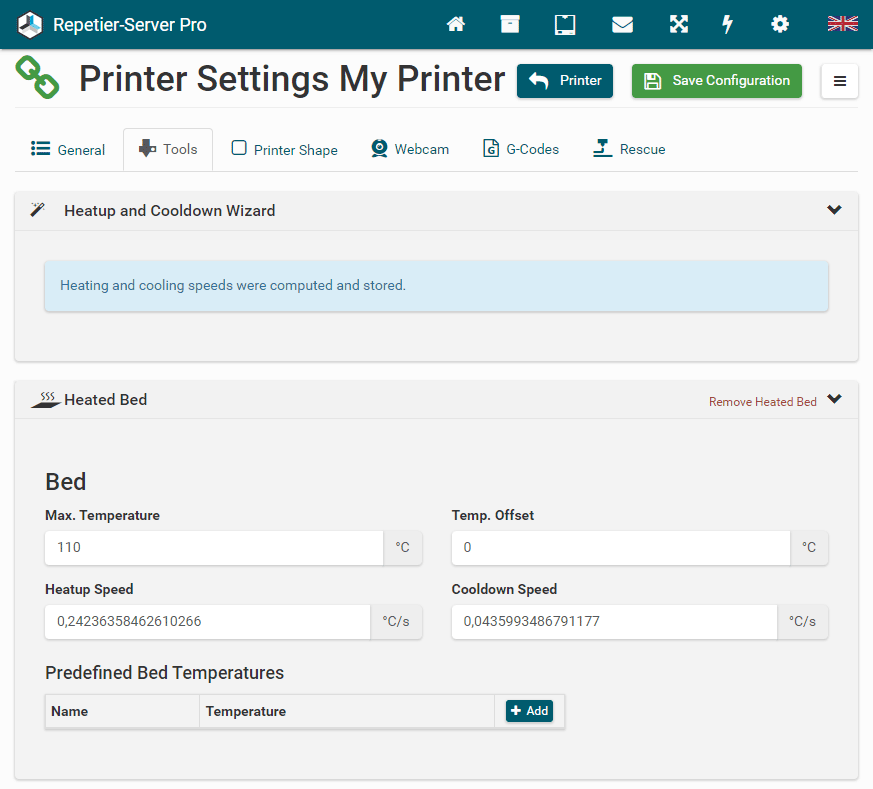

- When you see Heating and cooling speeds were computed and stored., the wizard is

finished.

The exact values for Heatup Speed and Cooldown Speed are stored

automatically.

![]()

G-Codes

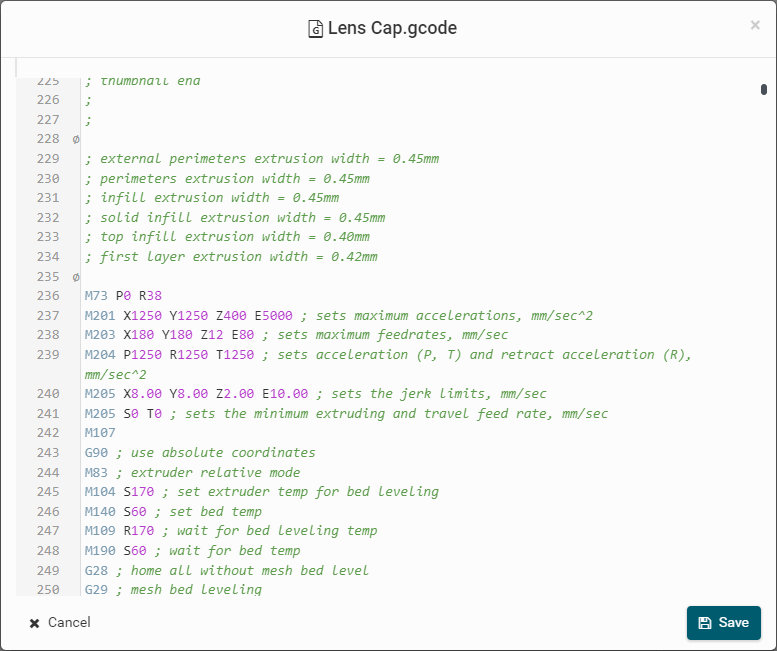

G-Code Script EditorFor g-code script editing we use a very comfortable code editor with a lot of features like syntax highlighting, code completion, code folding, multiple cursor, search & replace, matching close highlighting and more.

Default Keystrokes- ArrowLeft: Move cursor left

- ArrowRight: Move cursor right

- Ctrl-ArrowLeft (Alt-ArrowLeft on macOS): Moves one command part left

- Ctrl-ArrowRight (Alt-ArrowRight on macOS): Moves one command part right

- Cmd-ArrowLeft (on macOS): Moves to line start

- Cmd-ArrowRight (on macOS): Moves to line end

- ArrowUp: Move cursor up

- ArrowDown: Move cursor down

- Cmd-ArrowUp (on macOS): Go to document start

- Cmd-ArrowDown (on macOS): Go to document end

- Ctrl-ArrowUp (on macOS): Page up

- Ctrl-ArrowDown (on macOS): Page down

- PageUp: Page up

- PageDown: Page down

- Home: Move cursor to line start

- End: Move cursor to line end

- Ctrl-Home (Cmd-Home on macOS): Go to document start

- Ctrl-End (Cmd-Home on macOS): Go to docummnt end

- Enter: Insert new line

- Ctrl-a (Cmd-a on macOS): Select all

- Backspace: Delete char backward

- Delete: Delete char forward

- Ctrl-Backspace (Alt-Backspace on macOS): Delete group backward

- Ctrl-Delete (Alt-Delete on macOS): Delete group forward

- Cmd-Backspace (macOS): Delete to line start

- Cmd-Delete (macOS): Delete to line end

- Alt-ArrowLeft (Ctrl-ArrowLeft on macOS): Move cursor syntax part left

- Alt-ArrowRight (Ctrl-ArrowRight on macOS): Move cursor syntax part right

- Alt-ArrowUp: Move current line or selected liens up

- Alt-ArrowDown: Move current line or selected liens Down

- Shift-Alt-ArrowUp: Copy current line or selected liens up

- Shift-Alt-ArrowDown: Copy current line or selected liens down

- Escape: Cancel selection

- Ctrl-Enter (Cmd-Enter on macOS): Insert blank line

- Alt-l (Ctrl-l on macOS): Select line

- Ctrl-i (Cmd-i on macOS): Select parent syntax

- Shift-Tab or Ctrl-[ (Cmd-[ on macOS): Indent less

- Tab or Ctrl-] (Cmd-] on macOS): Indent more

- Ctrl-Alt-\ (Cmd-Alt-\ on macOS): Indent selection

- Shift-Ctrl-k (Shift-Cmd-k on macOS): Delete line

- Shift-Ctrl-\ (Shift-Cmd-\ on macOS): Cursor matching bracket

- Mod-z: Undo

- Mod-y (Mod-Shift-z on macOS): Redo

- Mod-u: Undo selection

- Alt-u (Mod-Shift-u on macOS): Redo selection

Some commands enclose a logical group of commands. With code folding you can hide these parts to get a better overview of your code. Here you can fold these command paths:

- @func ... @endfunc

- @while ... @endwhile

- @if ... @endif

- @dialogStart ... @dialogShow

You can fold this with the mouse by clicking the arrow marker next to the line number and with the following keystrokes:

- Ctrl-Shift-[ (Cmd-Alt-[ on macOS): Fold code

- Ctrl-Shift-] (Cmd-Alt-] on macOS): Unfold code

- Ctrl-Alt-[: Fold all

- Ctrl-Alt-]: Unfold all

When you start writing, you will get autocomplete suggestions for known commands and functions.

- Ctrl-Space: Start completion

- Escape: Close completion

- ArrowDown: Move completion selection down

- ArrowUp: Move completion selection up

- PageDown: Move completion selection up

- PageDown: Move completion selection down

- Enter: Accept completion

As soon as you mark a foldable function or brackets, the counterpart is automatically highlighted.

Search & Replace- Mod-f: Open Search Panel

- F3, Mod-g: Find Next

- Shift-F3, Shift-Mod-g: Find Previous

- Alt-g: Go to Line

- Mod-d: Select next occurrence

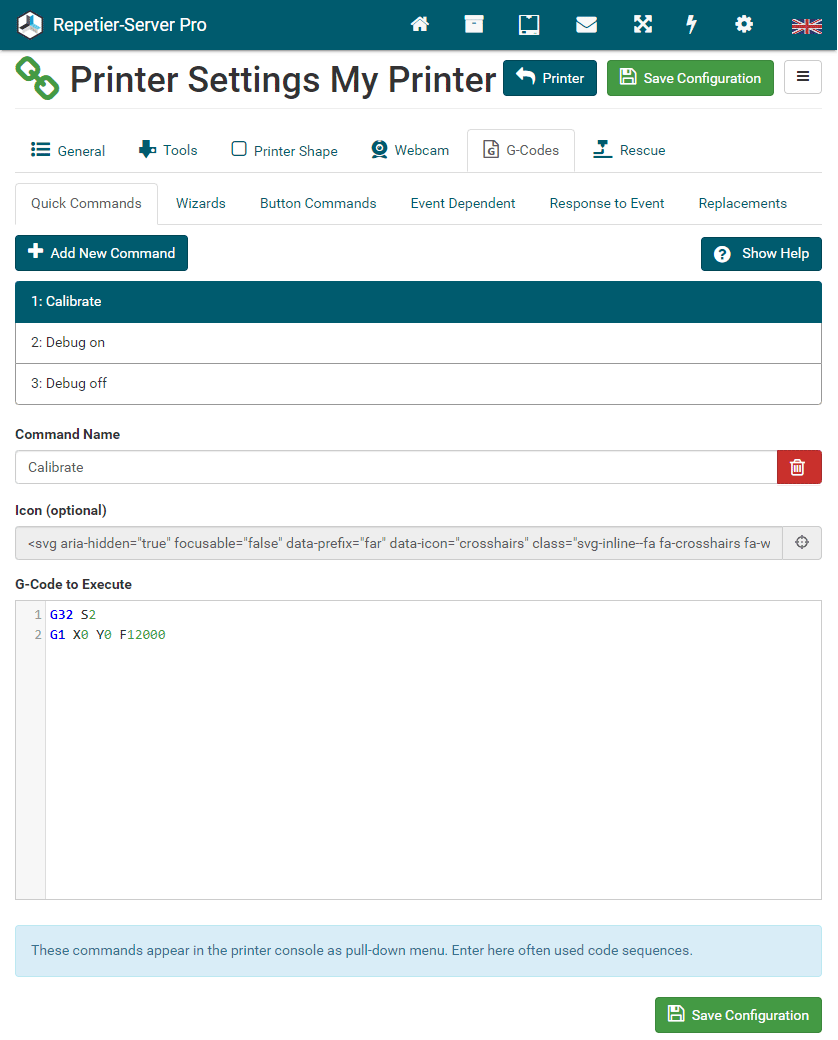

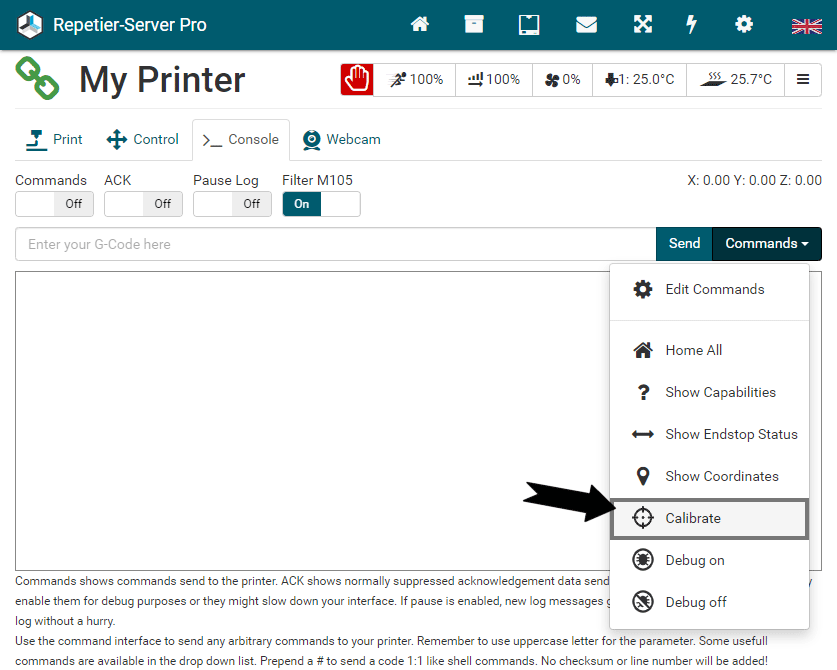

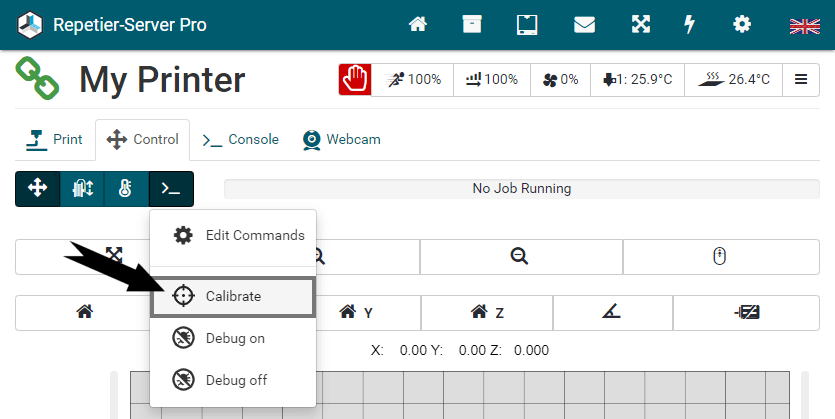

You can add multiple quick commands that you often use. These can also be sequences of commands e.g. to prepare printer. You can add own icons (optimally as SVG) and change the order of the entries by moving them with the left mouse button.

These quick commands appear at several places for selection.

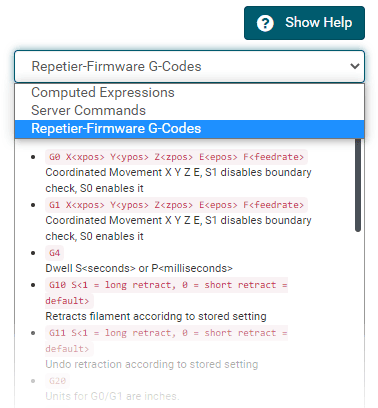

Click Show Help to show computed expressions, server commands and Repetier-Firmware G-Codes.

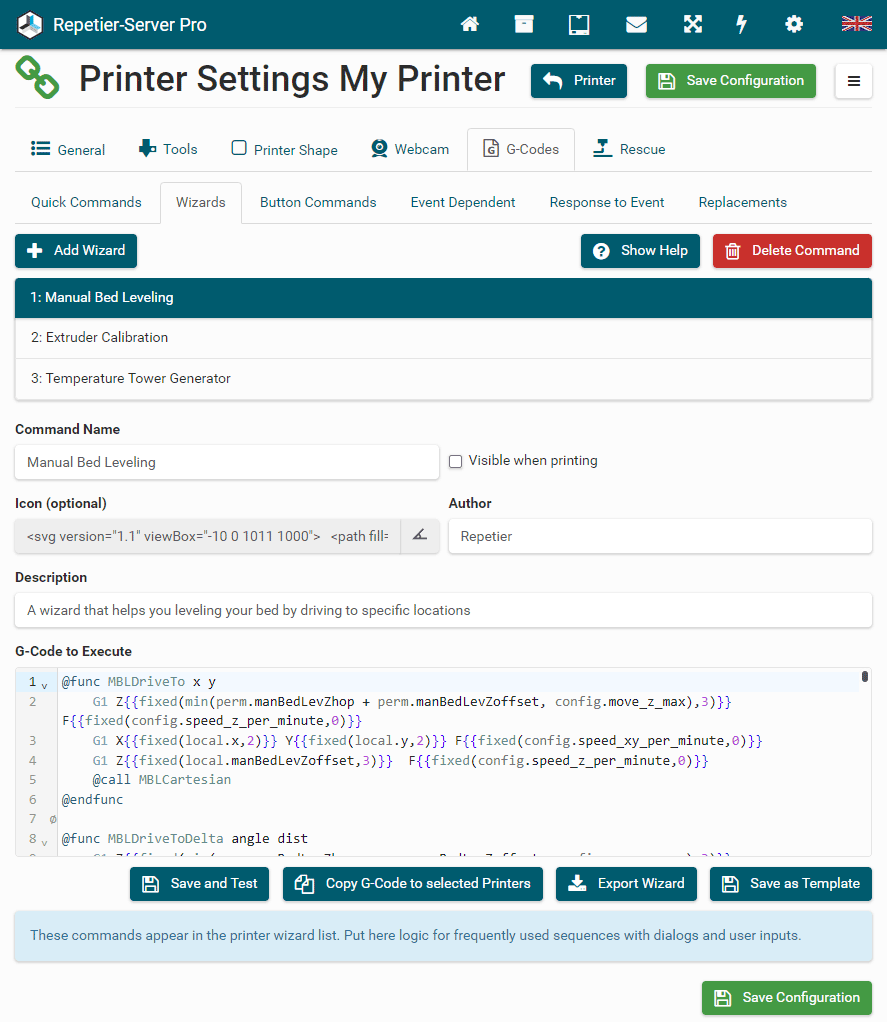

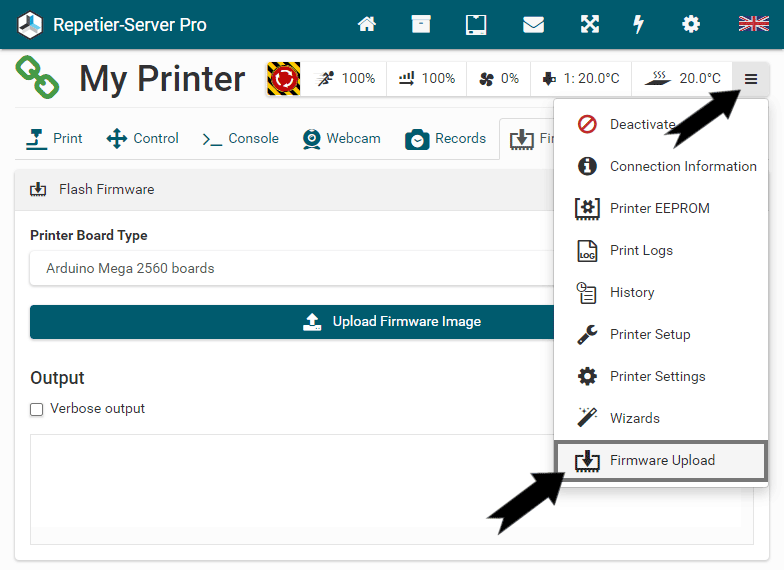

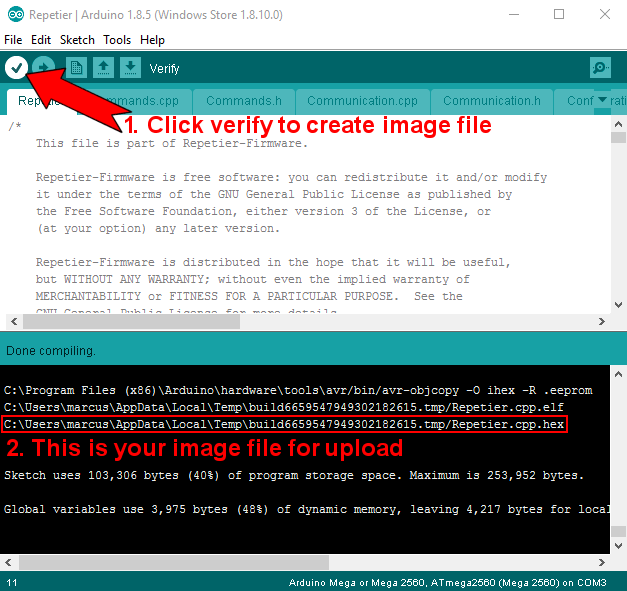

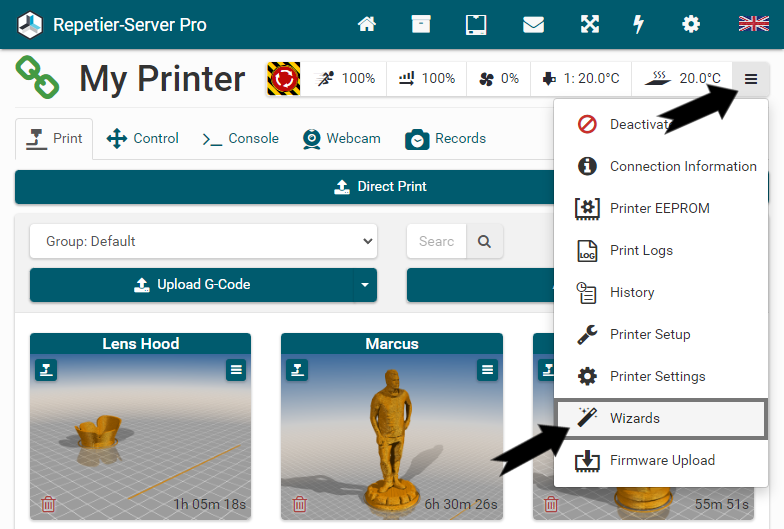

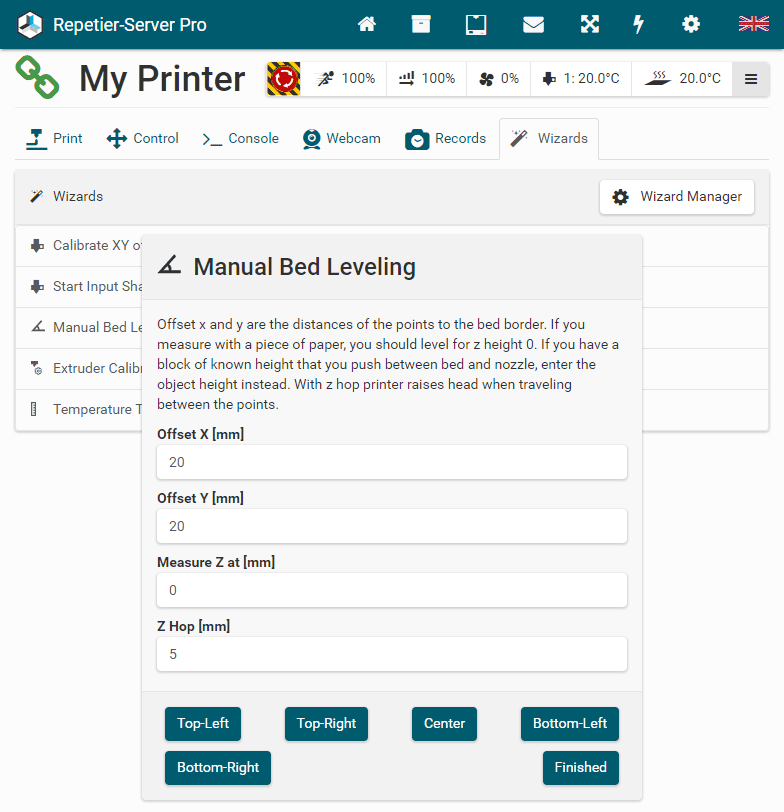

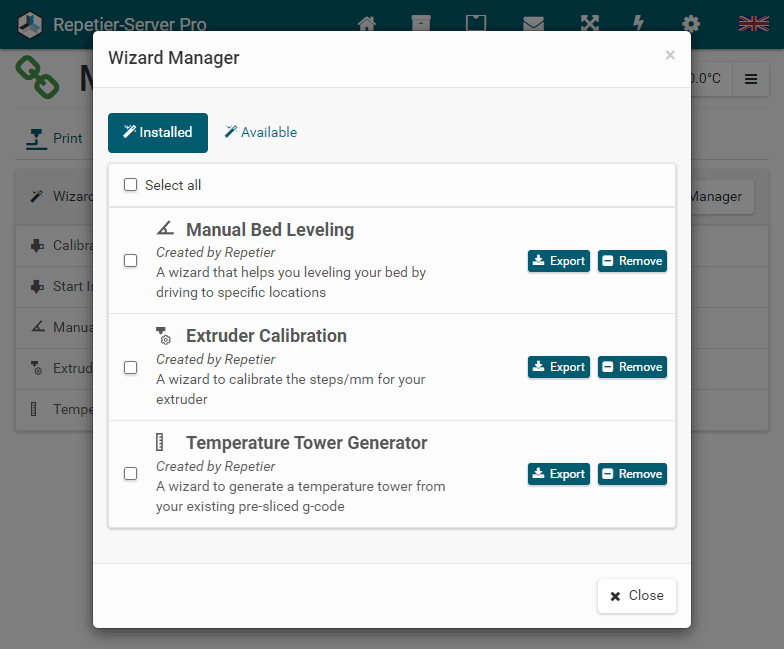

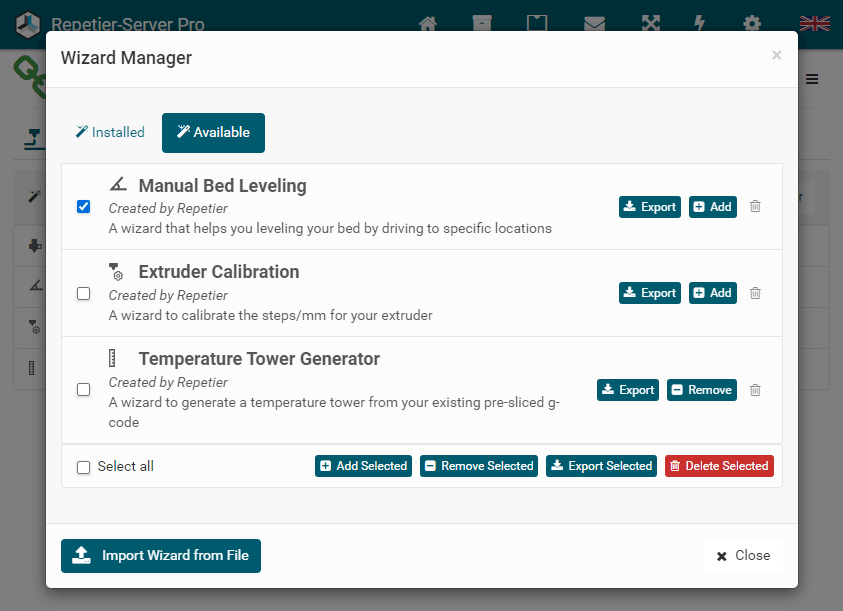

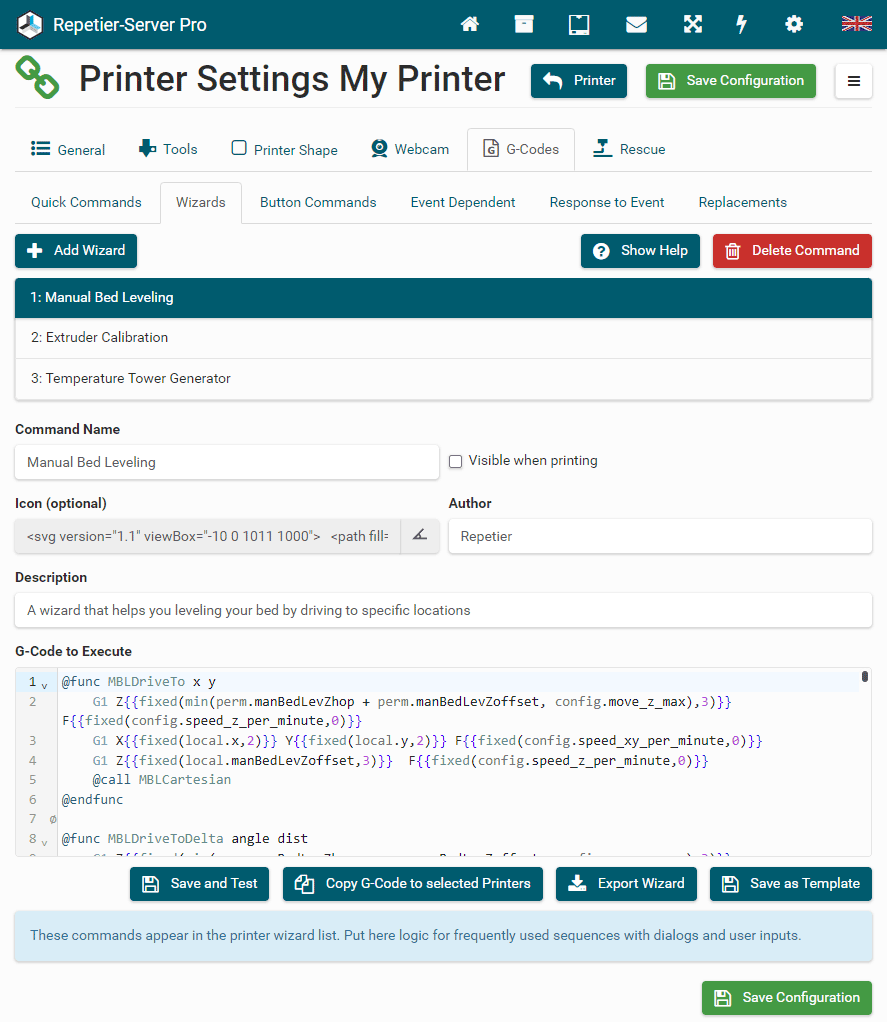

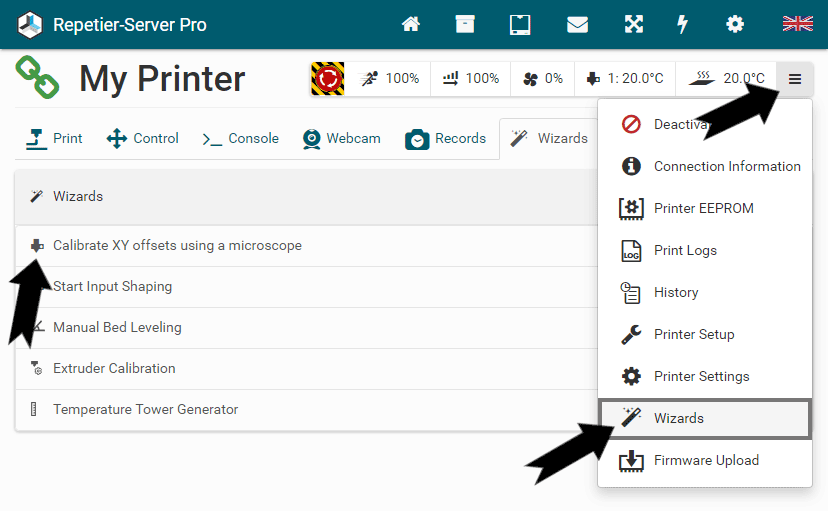

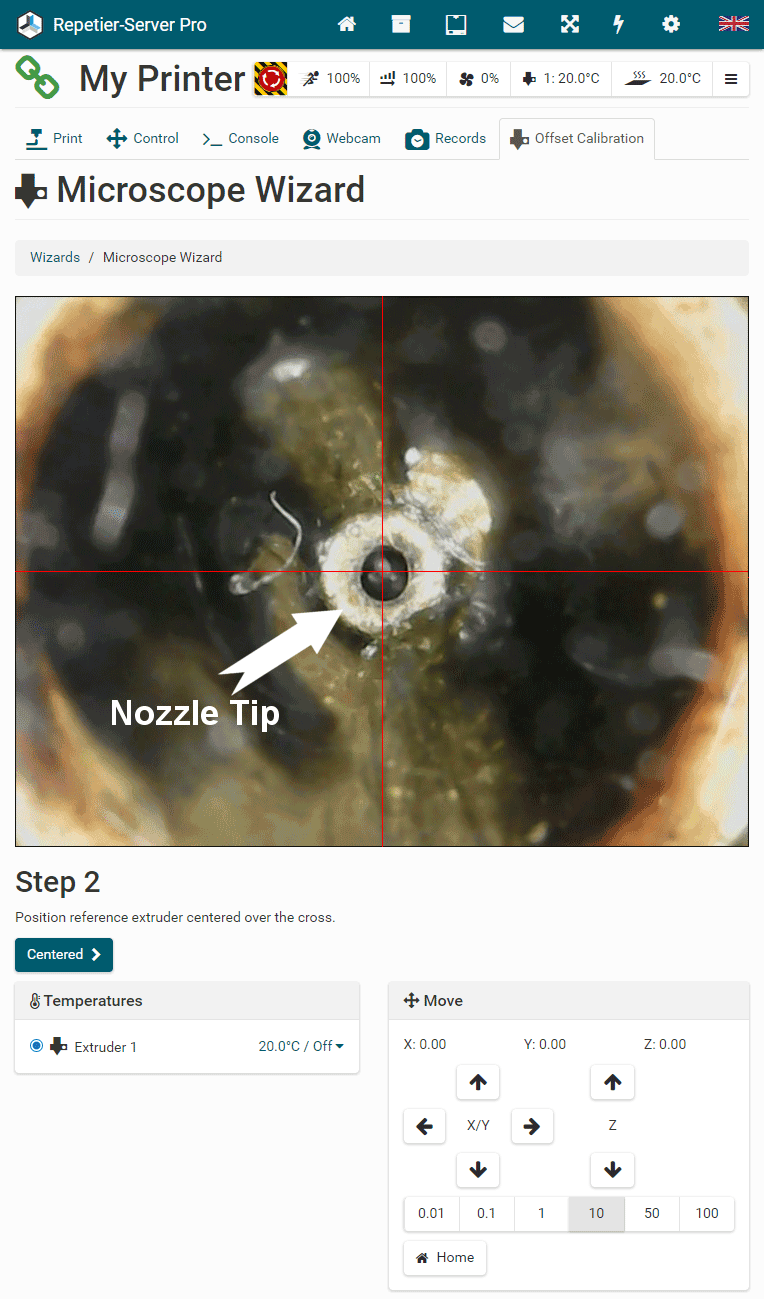

Wizards

WizardsHere you can add your own wizards, that will appear in the printer wizard tab.

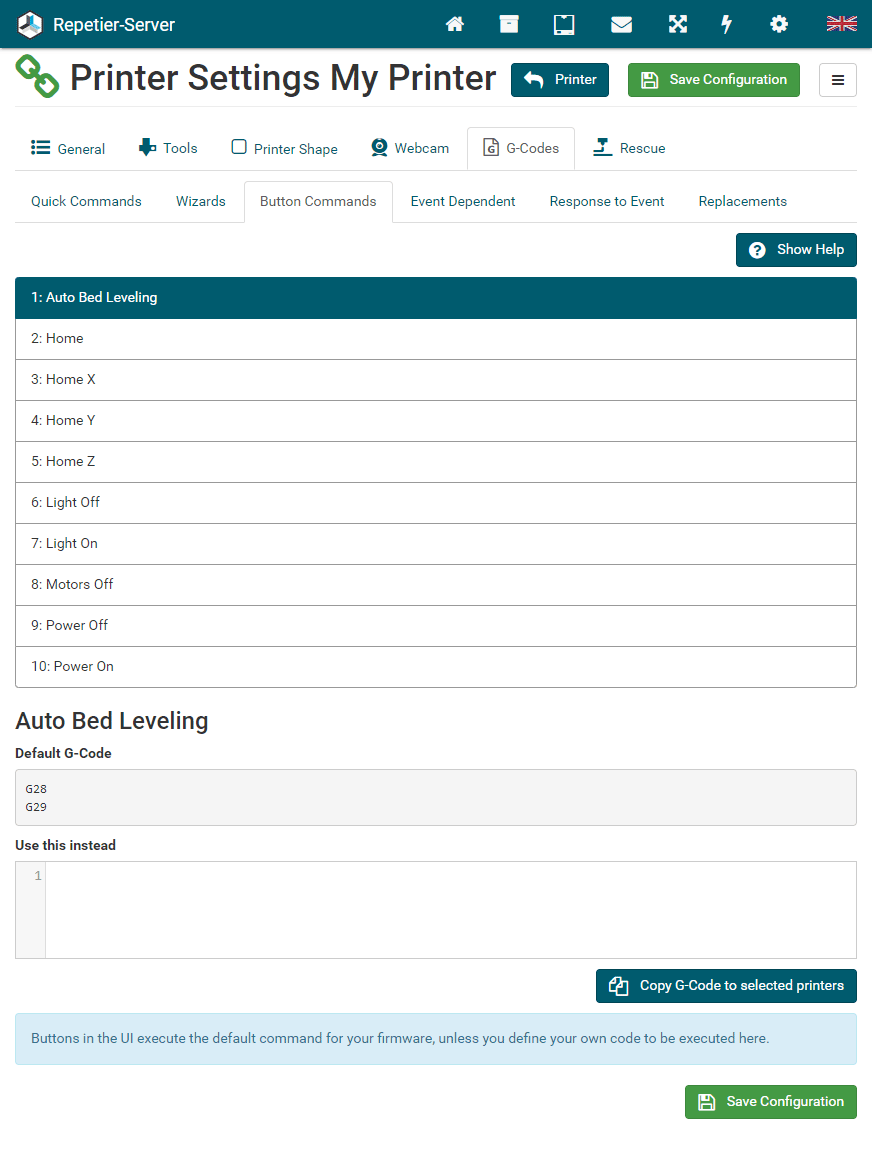

Button Commands

We normally execute the default commands in the UI. Here you can define your own codes if necessary.

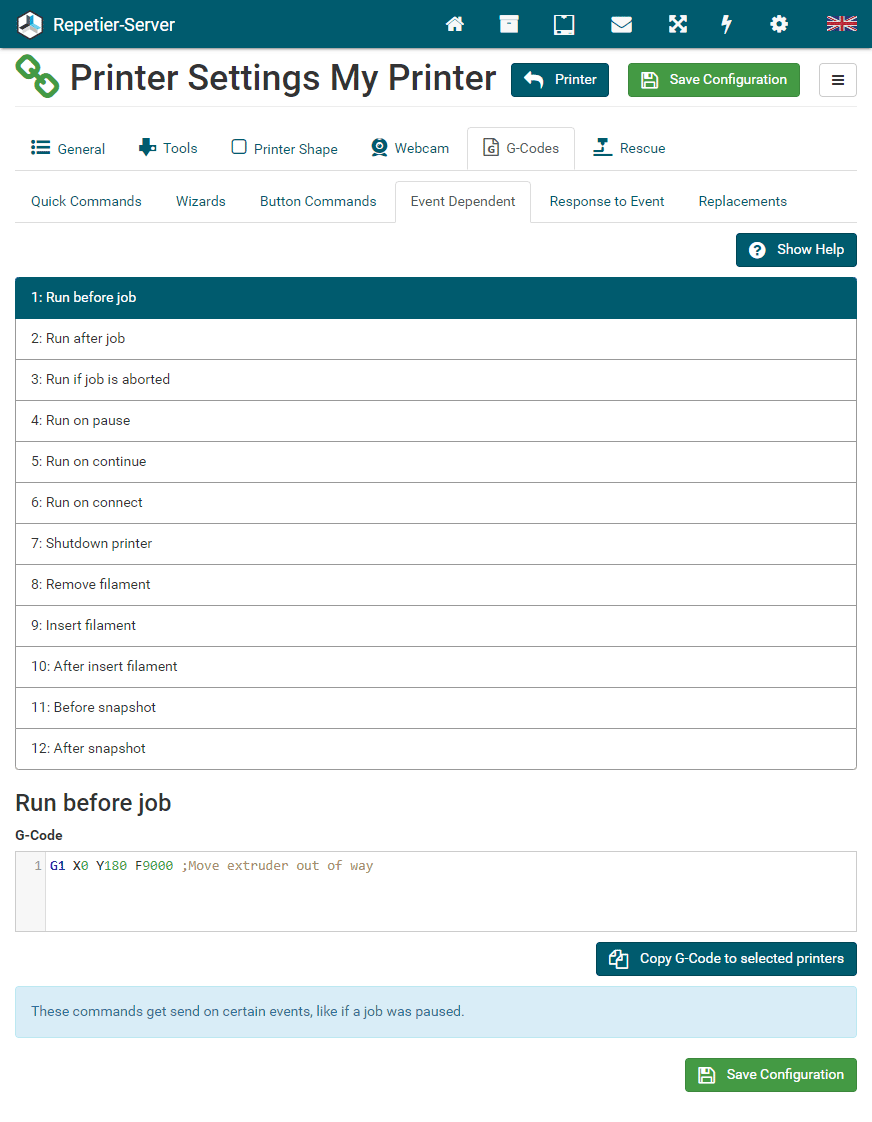

Event Dependent

During printer handling there are several special times in which you might want to execute additional commands. For example when you pause a print, the head would just stay where it is and causes a blob. So what you want is to move to a save place on pause. To do this, you add "G1 X0 Y200 F12000 ;Move extruder out of way" to the Run on pause event. Now every time when a pause occurs the head will move to the left back of your bed.

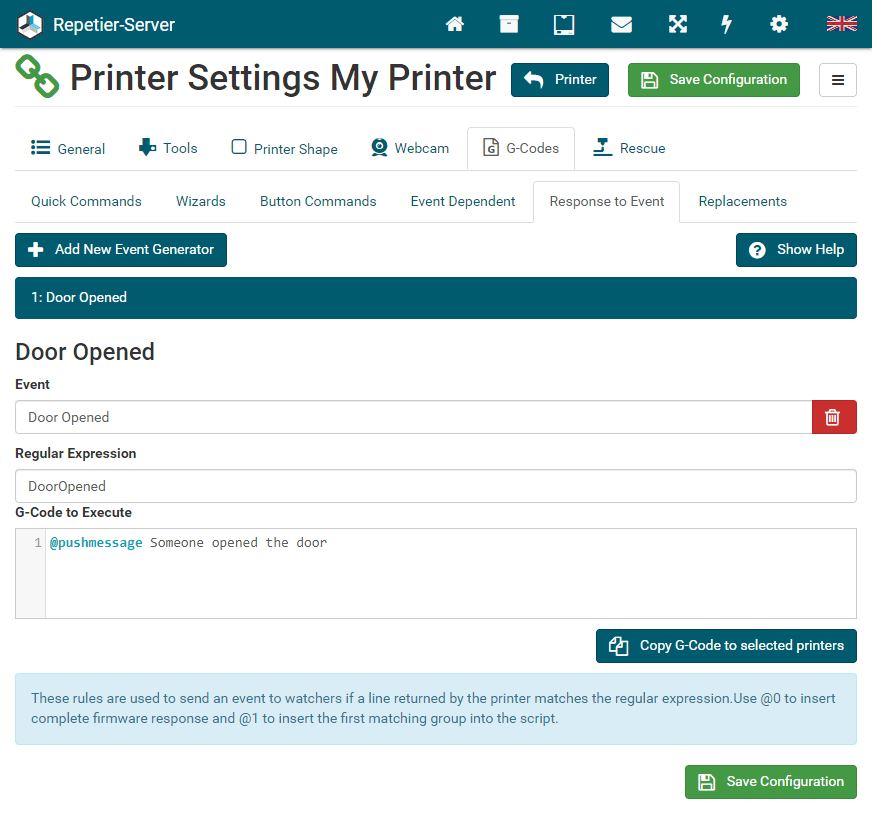

Response to Event

Sometimes you might want to execute some g-codes or server commands when the firmware sends a special string. Here you define which commands to execute on such a string. The string to look for is defined as regular expression. On https://regex101.com you can test your expression against one or more test strings to verify it is working, and you find also a quick reference to the special chars in regular expressions. It also marks the groups detected which you can use in the generated commands. Note that due to delays there might be other commands between that causes the output and your g-code to execute.

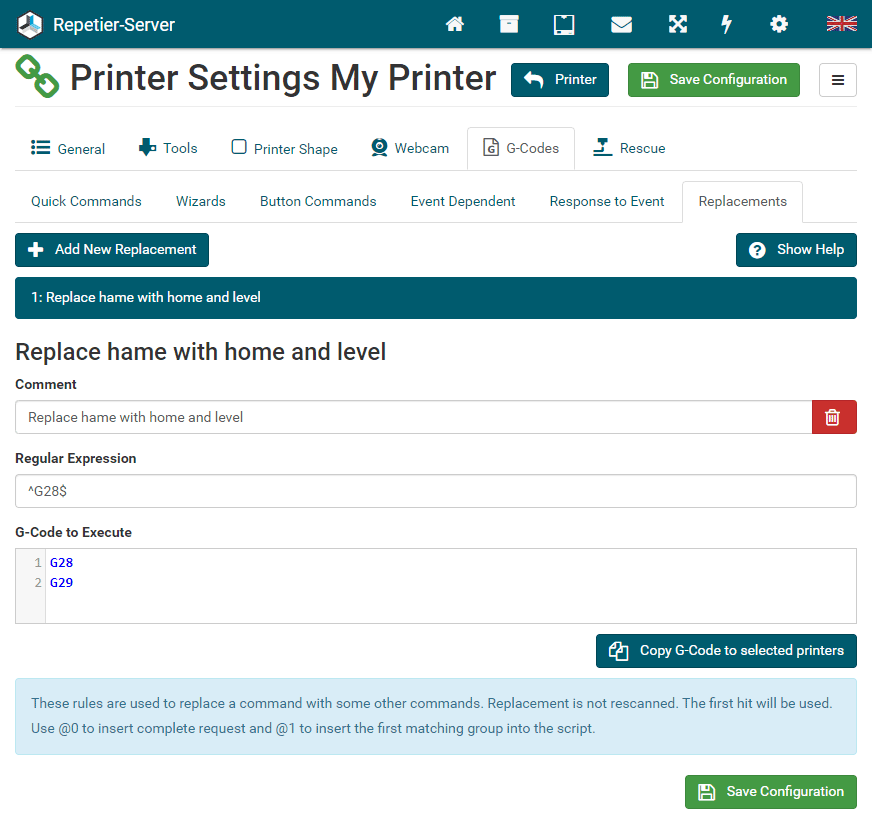

Replacements

Different printer firmwares may need commands in a different syntax than we would normally send. The replacements replace on the fly sent commands by the replacement g-codes. E.g. if you hit the homing button, we will always send G28. If you always want a bed leveling after homing you can define the regular expression ^G28$ and then execute G28 and G29 instead. Then hitting the home button will just do that. But be aware that also all G28 in sliced files will execute these replacements!

Just like with response to events you enter a regular expression, and you can use the matched groups to reuse parameter in generated replacement code.

Regular Expressions

If you read until here, you may have noted that we use regular expressions at several places to match some strings. The simple reason behind this is, that this is much more flexible then just testing if a string is contained. Think of regular expressions as a simple but effective language to match strings.

Example: If we want to test if a command is a pure M114 command, it is not enough to test, if

a string contains M114. This would match M1144 as well as M114 L0. With

regular expressions this is very easy if you know that a hat sign (^) means line start and a dollar sign

($)

means end of line. So the simple expressions ^M114$ only matches a line that start

with M114 and has nothing after it.

Before we continue describing some use cases, you should know great page for testing and alanysing regular expressions. When you call https://regex101.com/, you can write and test your own expressions, to see what they do. Current we use the PCRE library (PHP < 7.3). So select that library as regex variant and you should get the same results as Lafayette Rapid Prototyping Lab. To understand what we describe here, it would be best to open the tool and test the examples and play with them. The tool also offers help to possible commands, so anything not mentioned here can be read there. Our expressions are normally tested with case-insensitive flag set!

Character detection

The main part is always detecting a list of characters. So we start with them first. Any

character and digit is matches as is. So "ello" will match "Hello" as well as "Hello World".

But sometimes at one position different values can appear. Lets say we want to match the words "hot"

and "got" with one expression. For this we can use the [] operator. The content in the brackets

define what matches. So our 2 words could be matched with [gh]ot. Also frequently

needed is a case where it can be anything except a small list of letters. In that case use [^gh]

to allow any character except g and h.

Also very useful is the catch all sign ".". At a place where we have a dot any sign can be. So

T. will match Tx, Tc or T0.

There are also some useful sequences that denote groups frequently used. The following table shows the important ones.

| . | Matches all characters |

| \d | All digits |

| \D | Everything, except digits |

| \s | Any white space (space, tab, return, newline) |

| \S | Everything, except whitespaces |

| \w | Matches any letter, digit or underscore. Same as [a-zA-Z0-9_]. |

| \W | Everything, except what matches \w |

You will later see that many symbols like (, ), [, ], ., {, }, +, *, ? have special

meanings. If you want them as character, instead of the language symbol you need to put

a backslash before it to escape the character. So to match the term "Hi." but not "Hix" the expression

would be

^Hi\.$.

Quantification

Often just matching chars is not enough. If you need to match 2 words seperated by unknown content in between, you need a variable number of dots. For this we can add a quantifier that defines how often the previous match must be hit. Before I show the usage, here a list of quantifiers:

| ? | Zero or one time |

| * | Zero or more times |

| + | One or more times |

| {x} | Exactly x times - replace x by number |

| {x,} | At least x times |

| *? | Lazy quantifier. Select only minimum amount to match the remaining condition. |

Lets say we want to match any string that starts with "Hello" and ends with "world". This can be done

with ^Hello.*world$. This now matches "Hello world" as well as "Hello big world".

Unfortunately

it also matches "Helloworld". So if we want at least character in between, we write the expression

like this: ^Hello.+world$ or ^Hello.{1,}world$.

Groups

Sometimes you might want to use a part of a match for an other command that gets triggered

by the match. In this example we take the "Response to Event" tab of the printer configuration. When

the firmware name is send by the printer, you want a info dialog with the name. To achieve this, you send

M115 and wait for the proper response. As rule you enter FIRMWARE_NAME:([^ ]*).

You see the part in simple braces () is the group. It is the first and only one in the expression and

the docs say that @1 can be used inside the g-code part to replace it with the match of the first group.

What the term does is search for FIRMWARE_NAME: and then the next part is made a group. This group

contains the following characters until a space appears. Then the group ends.

So for a string "xyz FIRMWARE_NAME:Marlin PROTOCOL" we will get "Marlin" as first group match.

Alternative matches

If there are several possible terms that may match, you can separate them with a pipe (|). So the

rule ^ok|^wait would match any line that either start with "ok" or with "wait".

Speed

As you might already guess, regular expressions are not the fastest thing in the world. We precompile all expressions for fastest possible performance, but we need to test all active conditions, so the more you have, the slower everything gets. Apart from using only necessary tests you can do 2 more things to speed up everything:

- Use as simple as possible test. If you search for "xy" and you know it only appears at line start,

write

^xyand notxy. The first can skip matching very early while the latter case needs to parse the complete string to see if it fails. Also complicated constructs with back testing past chars can be very slow. - Use

@monitorCall(see server commands) instead of "Response to Event" when ever possible. This inserts an expression only for a limited time, where you expect a response. This is the way to go if you need responses in wizards or in functions.

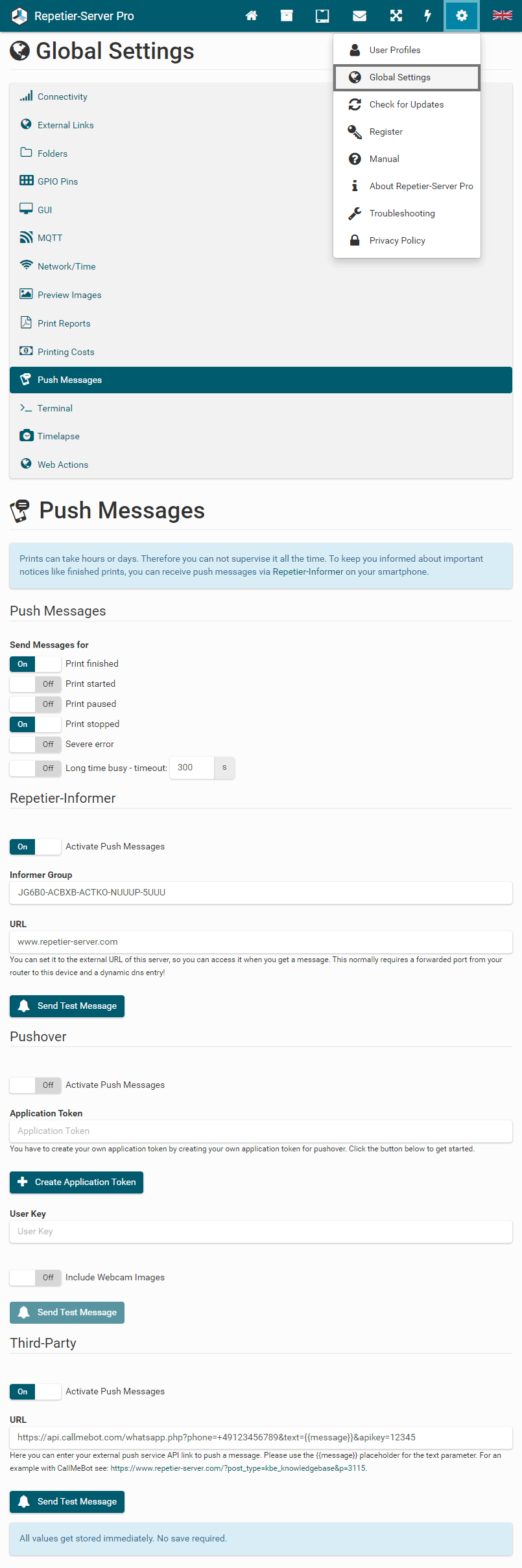

Push Messages

3D printing is cool, but it always takes some time and nobody wants to spend all the time sitting next to the printer. We have three different ways you can receive status messages. Click at top right of the browser window on the gear and choose Global Settings Push Messages to configure your push messages.

Select, which status messages you want to receive. These are available:

- Print finished

- Print started

- Print paused

- Print stopped

- Severe error

- Long time busy: Sends a message when the printer is busy for the time set here without running a slow command. This is normally the case when the printer is blocking communication e.g. due to a filament runout.

Repetier-Informer

Our Repetier-Informer app is available for Android and iOS devices. This will give you the desired status reports via fast and free push messages to your smartphone and/or tablet.

You have to enter an informer group you have created in your app.Scan this qr code to download Repetier-Informer:

Pushover

You can use the Poshover app to receive status messages. In addition, a current webcam image can always be sent along.

You have to create an application token. Use this link to create the applikation token with predefined settings.

You have a limit of 10.000 messages per month. The limit is set by Pushover.

Third-Party

Here you can enter an URL to your externam push service API like CallMeBot. Please use teh {{message}} placeholder for the text parameter.

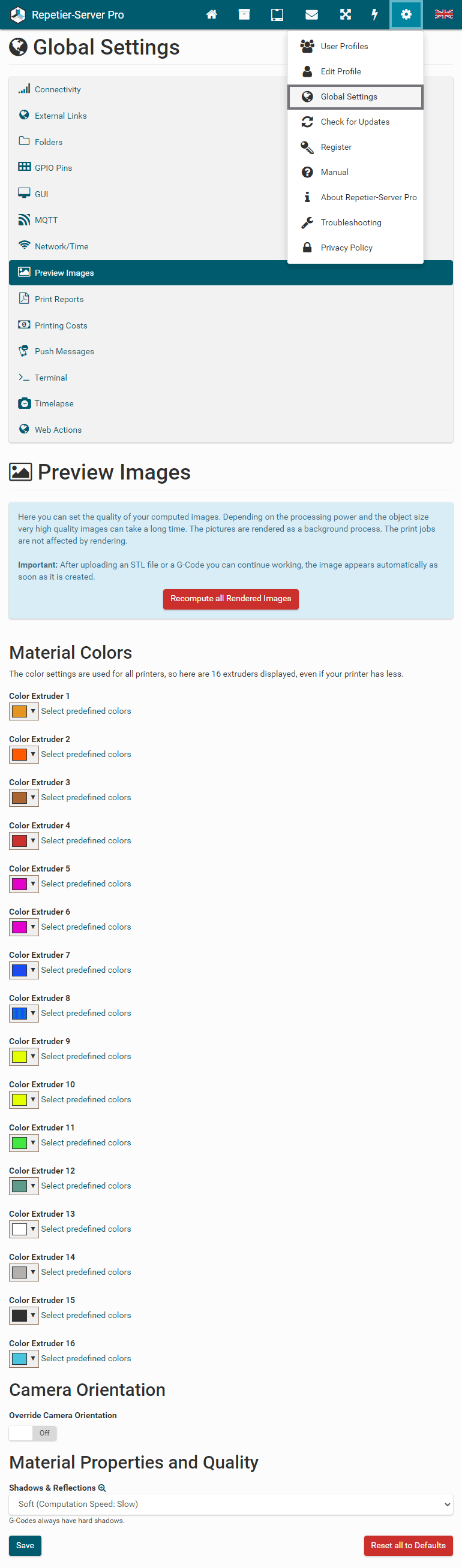

Preview Images

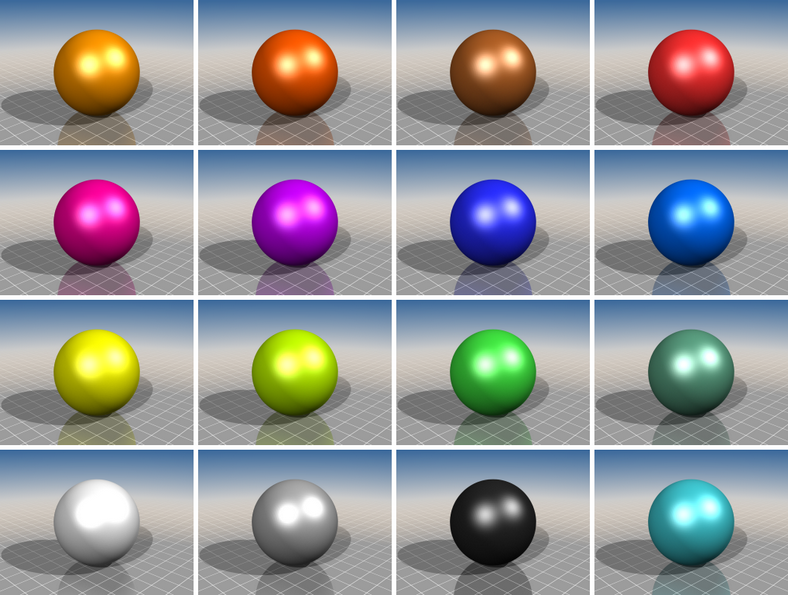

Lafayette Rapid Prototyping Lab creates preview images for all uploaded g-codes and STL files, so that you can easily browse through your models and see them. To set the quality and colors, go to and choose Global Settings Preview Images.

Here you can set the material colors for each extruder. The color settings are used for all printers, so here may be more extruder displayed as you have.

To set the color you can enter the rgb values in hexadecimal format, use our color picker or click Select predefined colors and choose one of our color proposals.

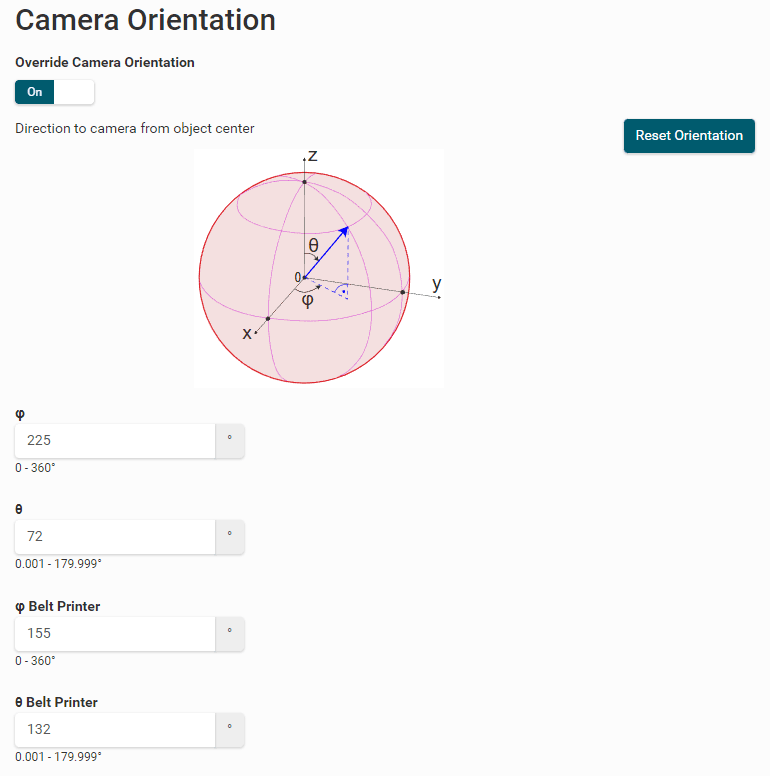

If you want, you can change the camera orentation of your preview images.

The view for camera orientation is from the center of the model. You specify here the two polar

coordinates in whose direction the camera should be.

For normal printers, you should look at the XY plane (θ should be less than 90° to look at

it from above), for belt printers, you should look at the XZ plane, so that you look in the direction

of positive Y (φ should be less than 180°).

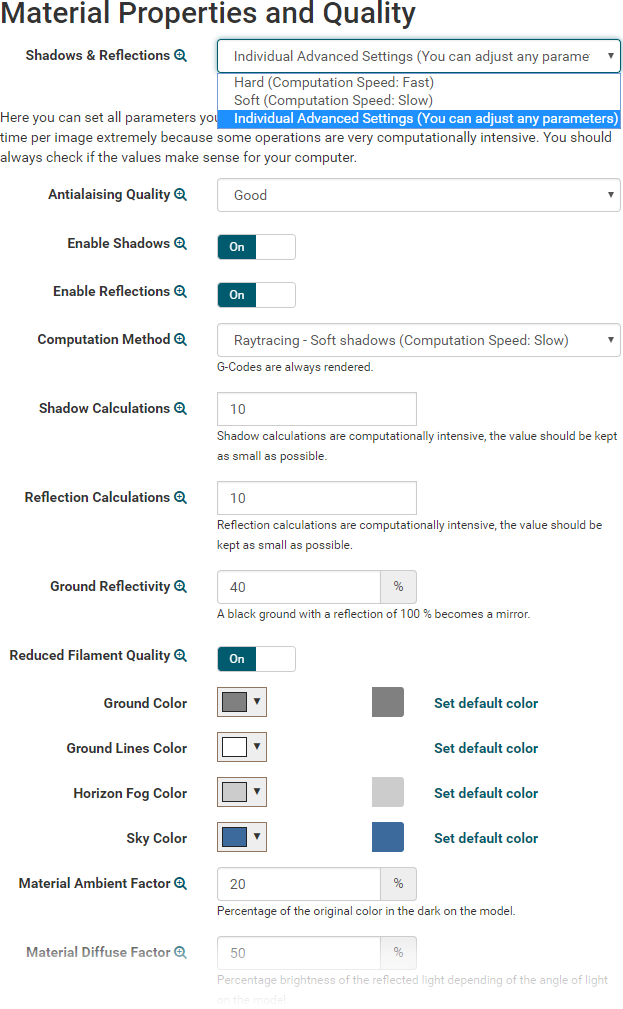

Normally you just have to choose between hard and soft shadows for STL files (G-Codes always have hard shadows). Soft shadows take much more time for rendering. If you select Individual Advanced Settings, you can set all parameters like antialiasing quality, shadows, reflections, colors of bed and horizon, lights, ... manually. Note that some settings can extremely increase the computing time. For all the parameters you will get examples by clicking on .

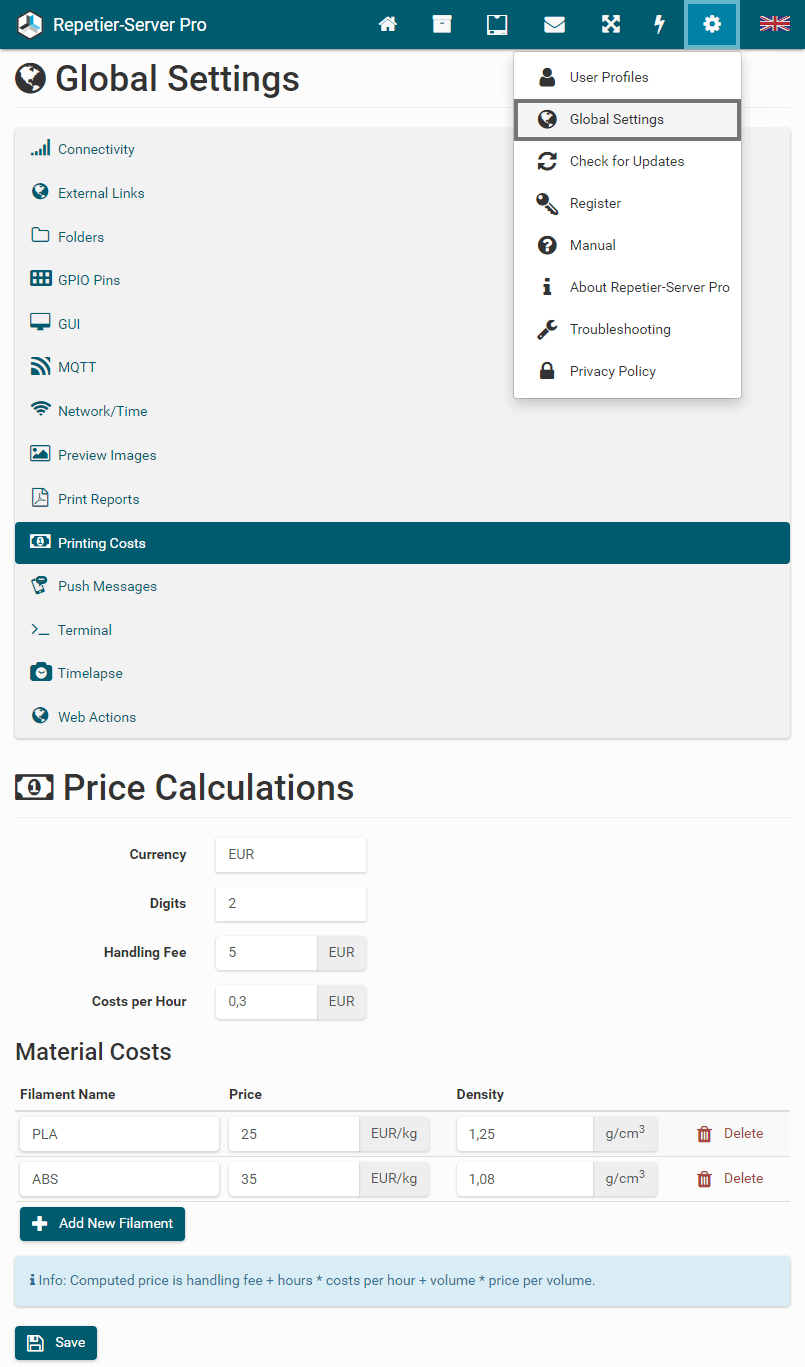

Printing Costs

With Lafayette Rapid Prototyping Lab you can calculate in advance what a print will cost.

Click at top right of the browser window on the gear and choose

Global Settings

Printing Costs to configure your price calculation.

Here you can set your currency, a handling fee (for professional offers) and costs per hour (e.g.

electricity

prices, hourly usage charge and printer wear).

Then you can create any number of filament types and for each a price per kg and a weight per cm³.

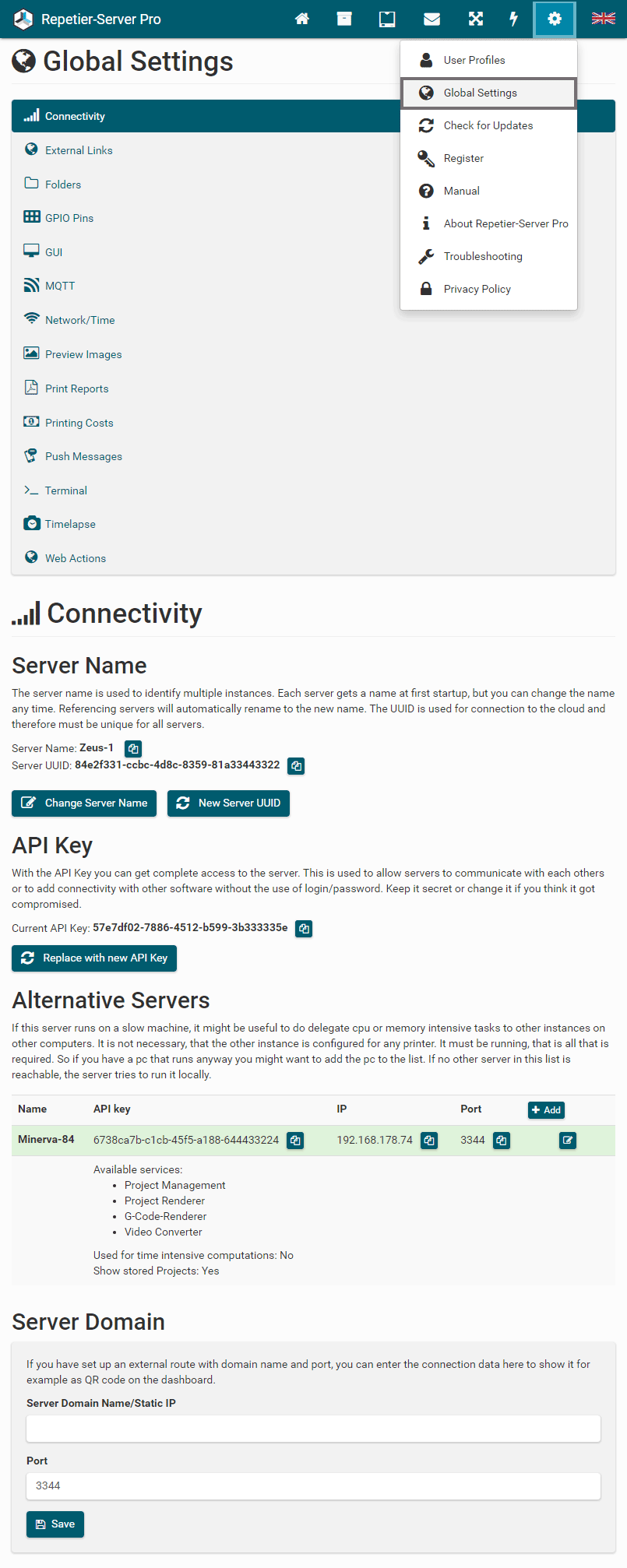

Connectivity

API Key

With the API key in your Global Settings you can get

complete

access to the server. This is used to allow servers to communicate with each others or to add

connectivity with

other software without the use of login/password. Keep it secret or change it if you think it got

compromised.

To change the API Key, click the button Replace with new API

Key.

If you do not want to give complete access to the server, use the API Key from a User at

User Profiles. Here the server gets the same rights as the

chosen

user.

Server Name

Each server installation has an own server name and helps to identity your installation when running multiple instances and when you use the cloud to control all your instances. If you change your server name, referencing servers will automatically rename to the new name. To connect to the cloud, you need the UUID, which must be unique. If you copy a running server image, you might copy the UUID, so you could get two installations with the same id, which will cause troubles when you connect to the cloud. In this case, click New Server UUID before connecting to the cloud.

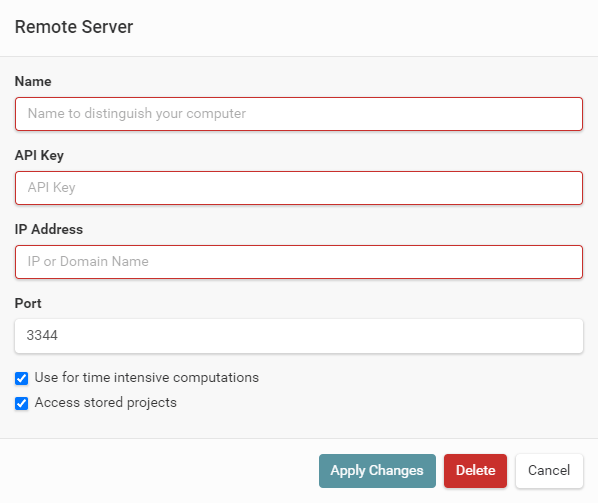

Alternative Servers

If your server runs on a slow machine, it might be useful to delegate cpu or memory intensive tasks to

other Lafayette Rapid Prototyping Lab instances on other

computers. It is not necessary, that the other instance is configured for any printer. It must be

running, that

is all that is required. So if you have a

pc that runs anyway, you might want to add the pc to the list. If no other server in this list is

reachable, the

server runs the task locally.

You can set if the remote server is used for time intensive computations and if it has access to stored

projects.

To add an new Lafayette Rapid Prototyping Lab instance, click the button

Add, enter a name, the API key

of the instance, the IP address and the port and click the button Apply Changes.

Notice: The server will always try to outsource computations, if there are cloud computers

specified. Therefore, it is important to set this only

to more capable and faster computers. The first accessible computer from the top of the list is used, so

that

the fastest computer should stand at the top.

Server Domain

If you have set up an external route with domain name and port, you can enter the connection data here

to show

it for example as QR code on the dashboard.

Depending on the NAT rules in your router, the port may differ from the port the server really uses.

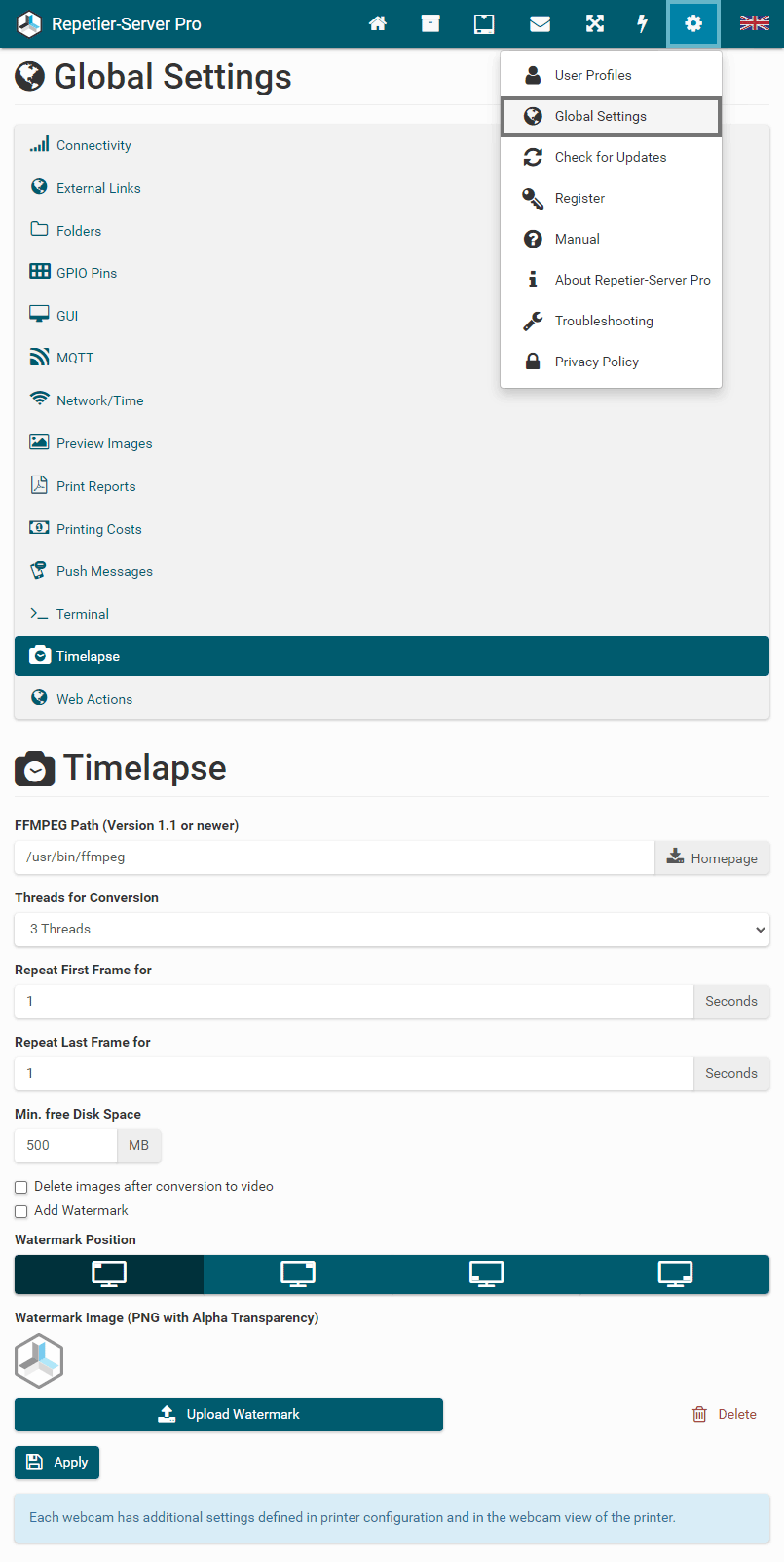

Timelapse

If a webcam is activated in the printer settings, you can specify that images are taken at predetermined intervals. These images can be played via the website like a video. If you want to export it as a mp4 video, you must install FFMPEG. Free download of FFMPEG (version 1.1 or newer) for all operating systems: https://ffmpeg.org/download.html

After installing FFMPEG you have to enter the path (eg C:\ffmpeg\bin\ffmpeg.exe or /usr/bin/ffmpeg),

that's

all. If a remote server is connected, rendering will be outsourced, if the remote server has also FFMPEG

installed.

Notice: Alternatively you can install

avcanv

instead of FFMPEG. Everything will work the same except repeat first/last frame, which will be replaced

with no

repetition. The executable must be named avconv to be detected automatically.

Threads for Conversion: If you have a multi-core processor, you can specify here how many threads will be used simultaneously to render the video.

Repeat First Frame for: Thus the print does not start immediately on the video, the first picture can be repeated for x seconds.

Repeat Last Frame for: Here the last picture can be repeated for x seconds.

Min. free Disk Space: To avoid that hard disk space runs out while the video is created, here you can specify how much disk space must be at least free, so that the video rendering will start.

Delete images after conversion to video: To save a lot of disk space, you can delete the pictures automatically after creating the timelapse video.

Add Watermark: Here you can specify if you want to embed a watermark in the video.

Watermark Position: Here you define, in which corner the watermark appears.

Watermark Image: Here you can upload your own image, which is used as a watermark. The image must be a PNG and may have alpha channel transparency.

Notice: Each webcam has additional settings defined in printer configuration and in the webcam view of the printer.

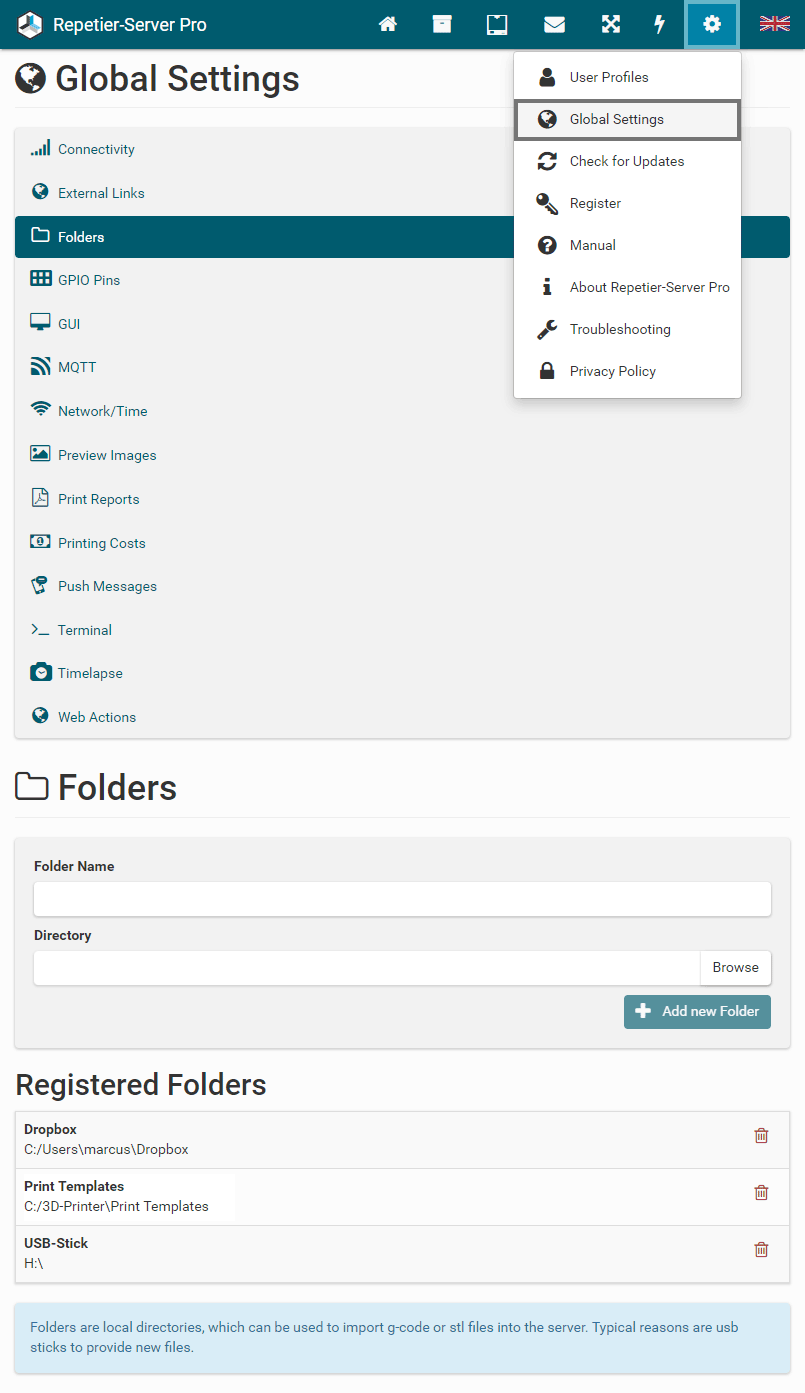

Folders

Here you can register local folders, which you can use to import G-Code or STL files into the server.

Typical

reasons are usb sticks or frequently used folders to provide new files.

You can enter a folder name for each folder. Click Browse to select the folder and

Add new Folder to save the folder.

Network/Time

If you use our image for Raspberry Pi, you can configure Network via access point mode or wired

connection. For

details click here:

https://www.repetier-server.com/download-images/

With such a setup you can configure your Network in Global Settings

Network/Time.

You can configure your PC to

connect to an existing WLAN or

to act as an access point. The settings have 4 blocks.

The block Available WLAN Router shows all available WLAN routers. Here you can connect to one of these. Click on the wanted router. If it is encrypted or the password is not stored you will be asked for the password.

The block Connection Settings configures some general parameters:

- Hostname - The name of your PC. It will appear with this name in your WLAN.

- SSID if in AP Mode - When working as access point, it will show this name as route name.

- Password - Here you can change your password for access point mode. The default password is 12345678.

- Channel if in AP Mode - The channel used for transmission. Depending on your country not all channels are allowed.

- Region - The country you are in. This determines which channels are available. You need to reboot to activate the changes.

- AP Handling - Define when the server should act as an access point.

First you should set the region in Connection Settings. Only with the correct region the adapter will work on the channels allowed in your country. You might also want to change the host name. That is the name that will appear in your routers or can be used as part of the URL, if your OS supports Bonjour/Zeroconf. The URL will be in our case http://repetier-server.local/.

The block Wired Connection allows overriding the default settings queried from the DHCP server. Normally there is no need to change anything here.

The block Time allows to set your time zone. This will be used for several time outputs.

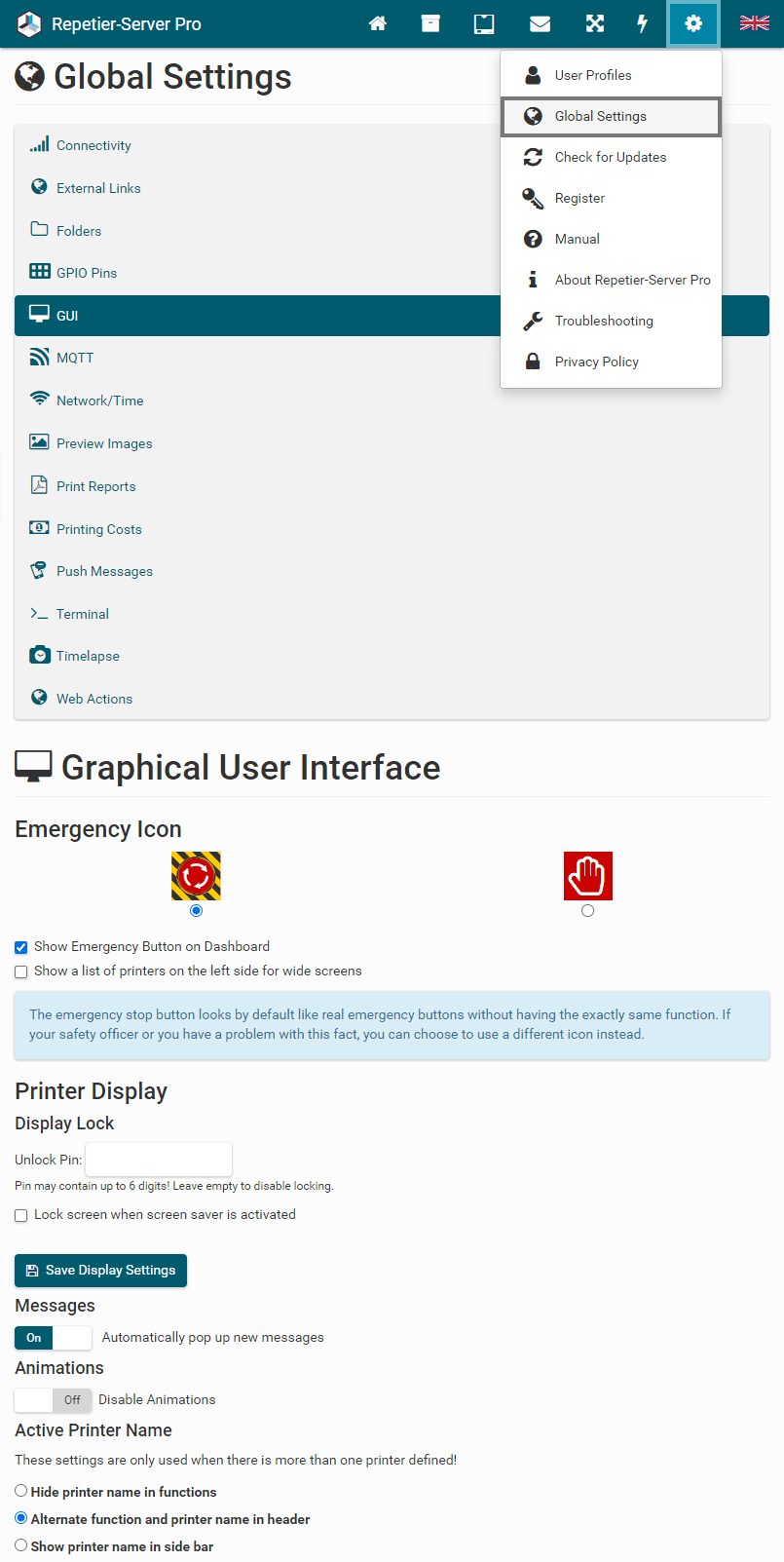

GUI

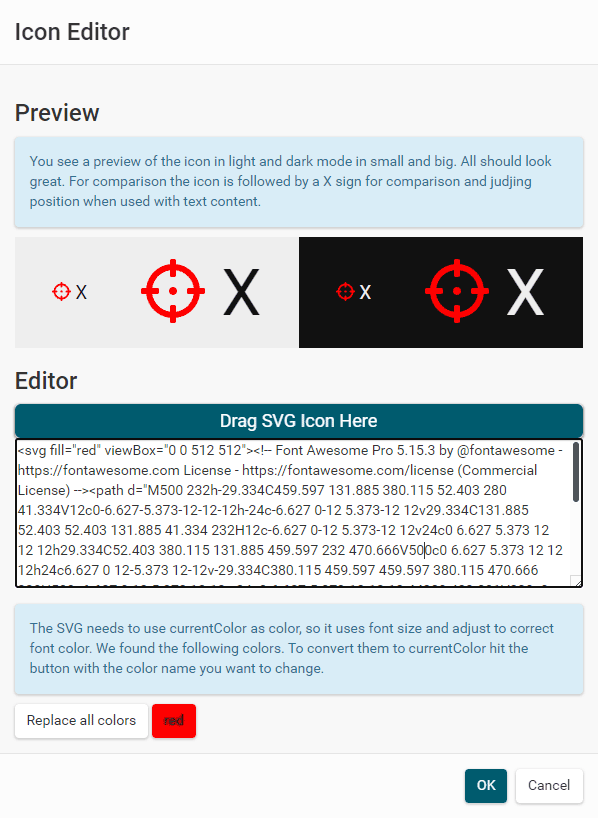

Emergency Icon

The emergency stop button looks by default like real emergency buttons without having the exactly same function. If your safety officer or you have a problem with this fact, you can choose to use a different icon instead.

If you select Show Emergency Button on Dashboard, an emergency button will be shown for each printer on the dashboard. To prevent unintentional clicking, the stop must be confirmed again.

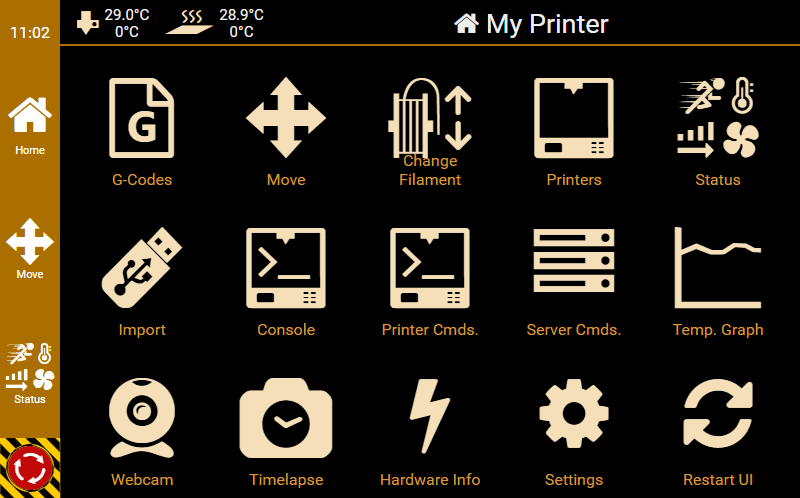

Printer Display

If you use our touchscreen interface on your printer, you can set a pin to unlock the display after the screen saver is activated, so that no unauthorized persons have access. You can enter a pin with up to 6 numbers. Then you can lock the printer display manually. Without a pin, you can not lock it. To activate the lock automatically when the screen saver starts, select Lock screen when the screen saver is activated. Because the printer display has no users, there is only one pin for all users.

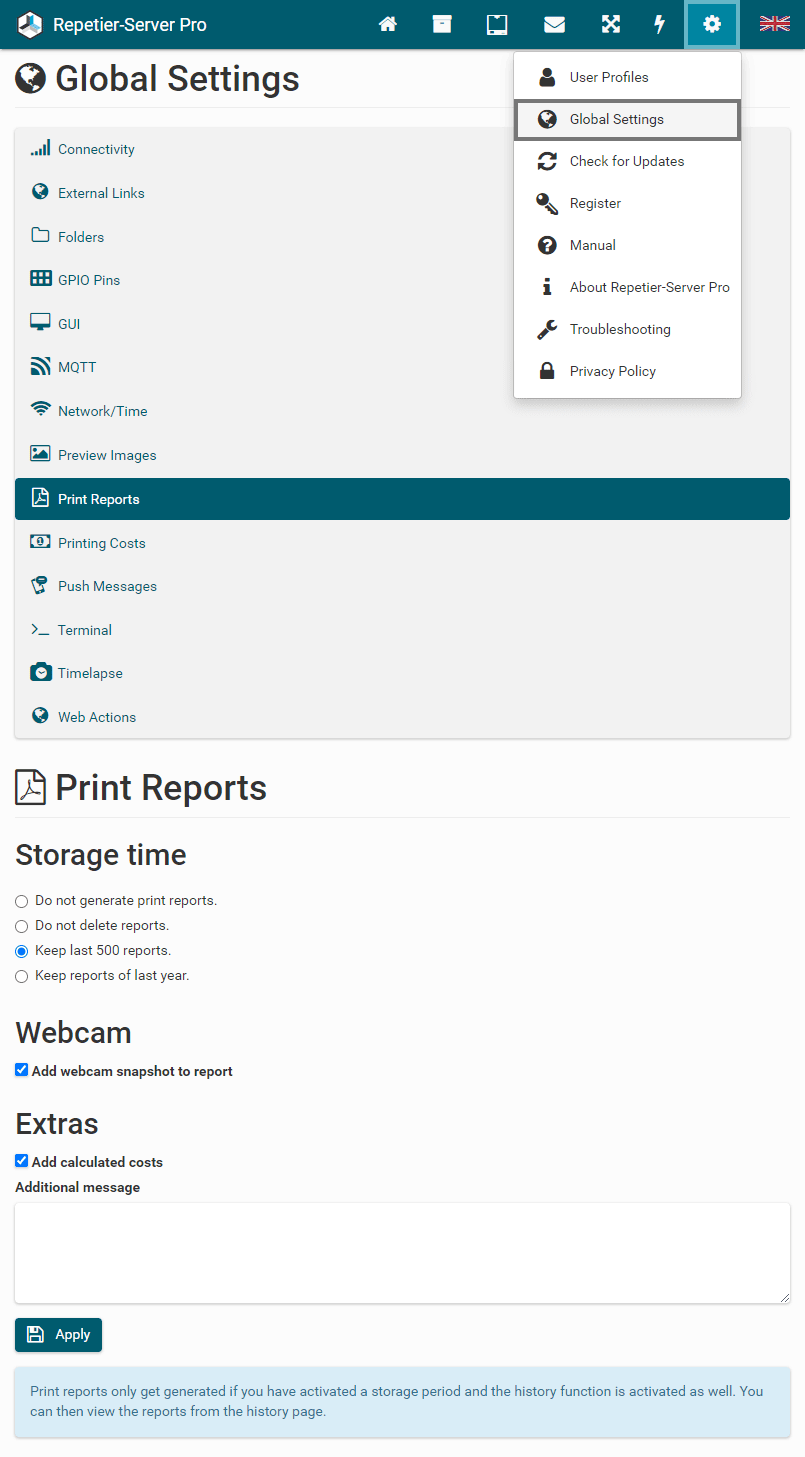

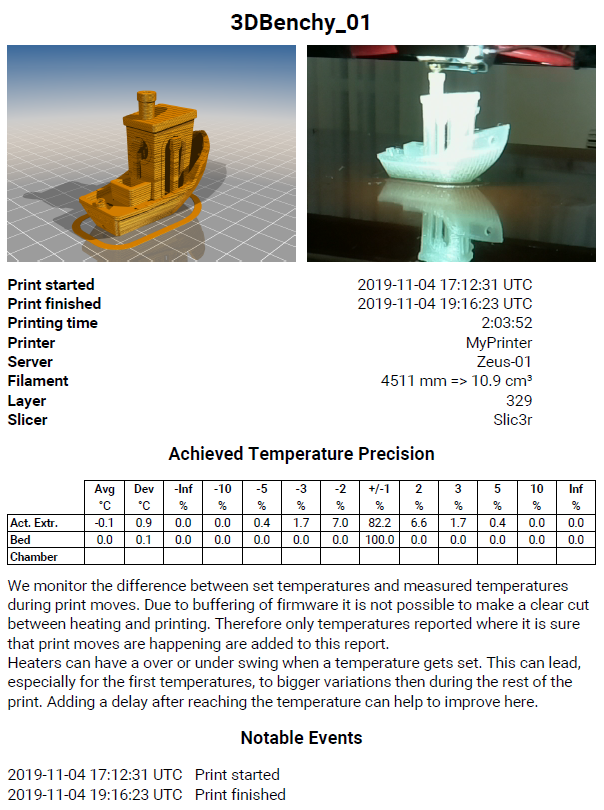

Print Reports

While you can already see in your print history when you printed which file, the reports added to the history offer more details about the prints and are also a great way to document your work in downloadable pdf files, e.g. if it is a commissioned work, and you want to deliver a print report.

The report contains a rendered preview image, and if you have a webcam, you can add a webcam snapshot of the finished print to the report as well. Due to the embedded images, the reports can be up to one MB, so you might want to reduce the number of stored reports or disable them completely. Deletions will happen in the next report generation. If you select Do not generate print reports., the saved reports will not be deleted.

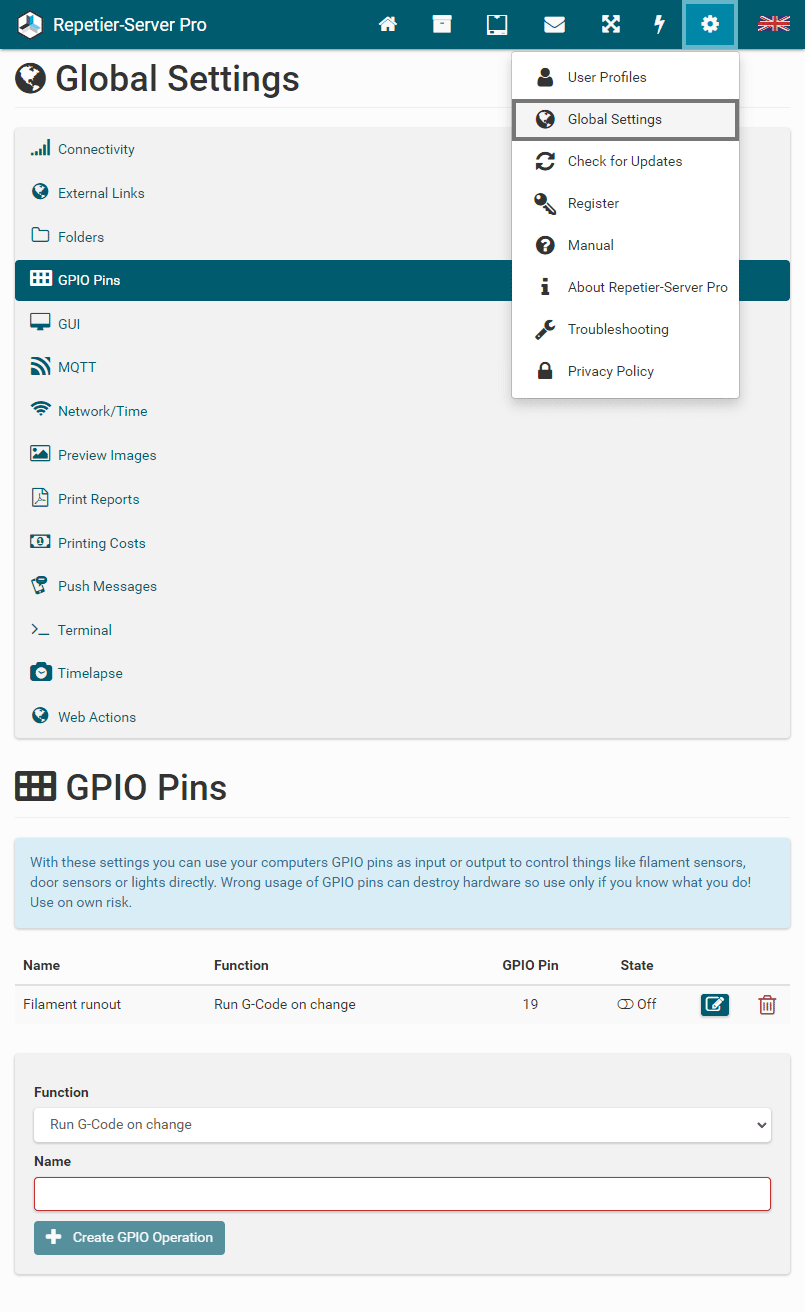

GPIO Pins

With these settings, you can use your computers GPIO pins as input or output to control things like filament sensors, door sensors or lights directly. Wrong usage of GPIO pins can destroy hardware so use only if you know what you do! Use on own risk.

For more information please visit our GPIO Tutorial:

https://www.repetier-server.com/gpio-tutorial/

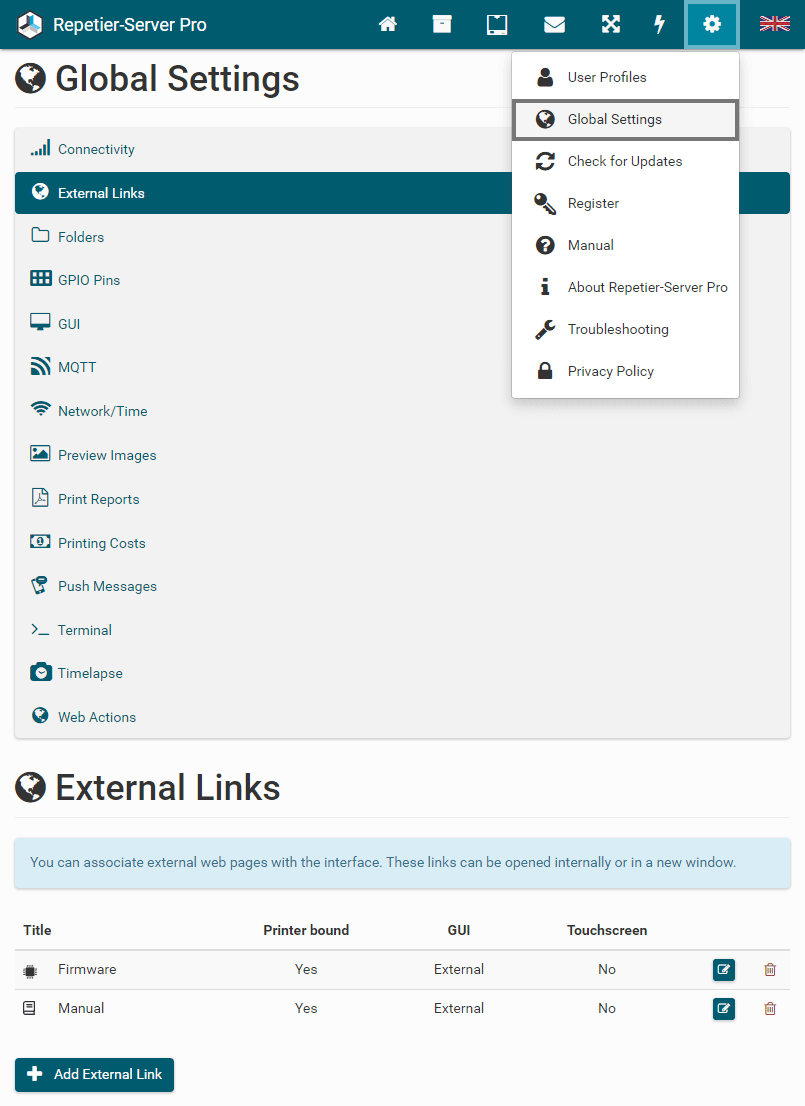

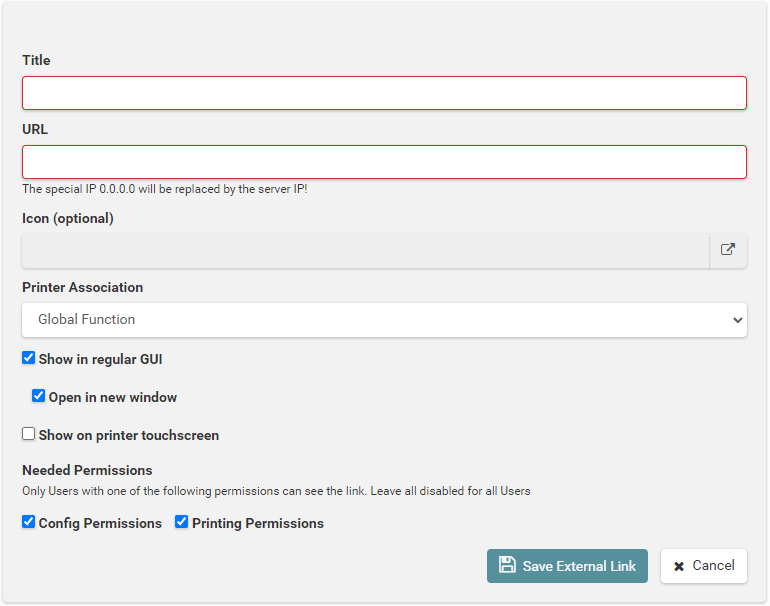

External Links

Here you can add individual links to Lafayette Rapid Prototyping Lab.

You can use the links as global functions or associate them with a specific printer. The order of the links can be changed by moving them with the left mouse button.

You can also add own icons. We strongly recommend using SVG graphics, as they are always scaled to the right size and can be adjusted to the color scheme. If colors are predefined in the graphic, they can be set to currentColor by clicking on the color, so that this color can be adapted to the color scheme by the program. However, PNG graphics can also be specified.

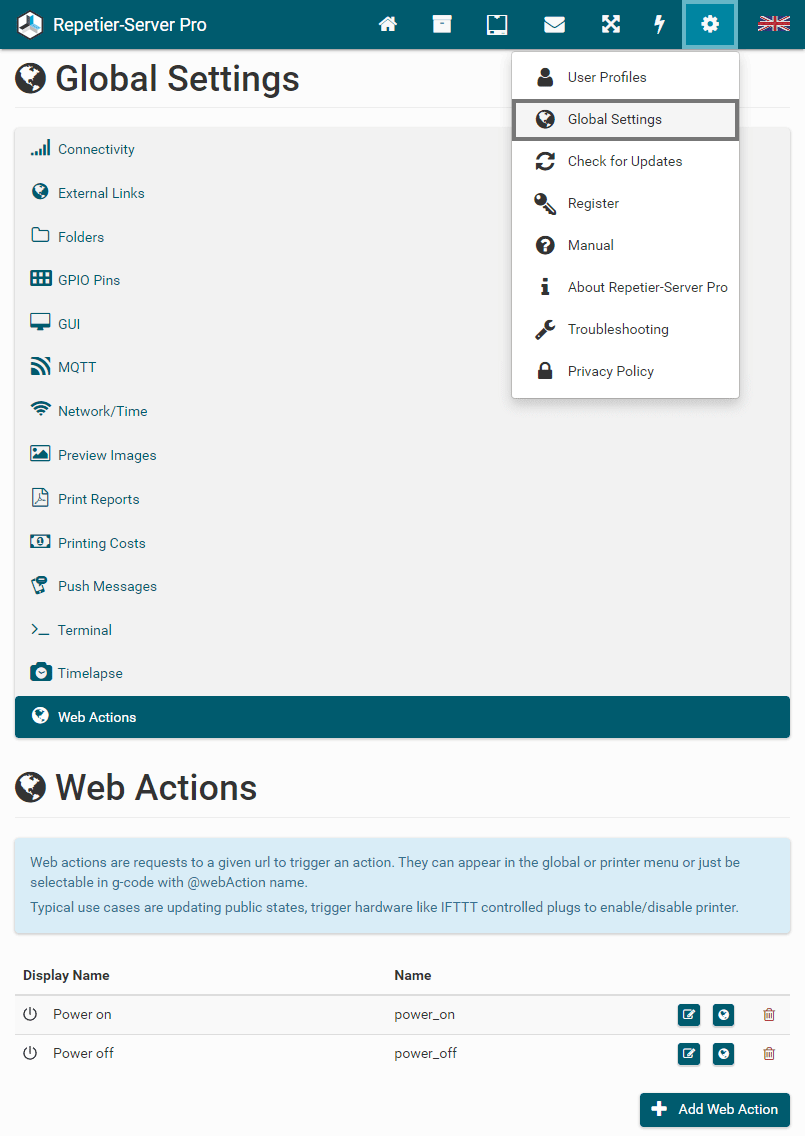

Web Actions

Web actions are requests to a given url to trigger an action. They can appear in the global or printer menu or just be selectable in g-code with @webAction name.

Typical use cases are updating public states, trigger hardware like IFTTT controlled plugs to enable/disable printer.

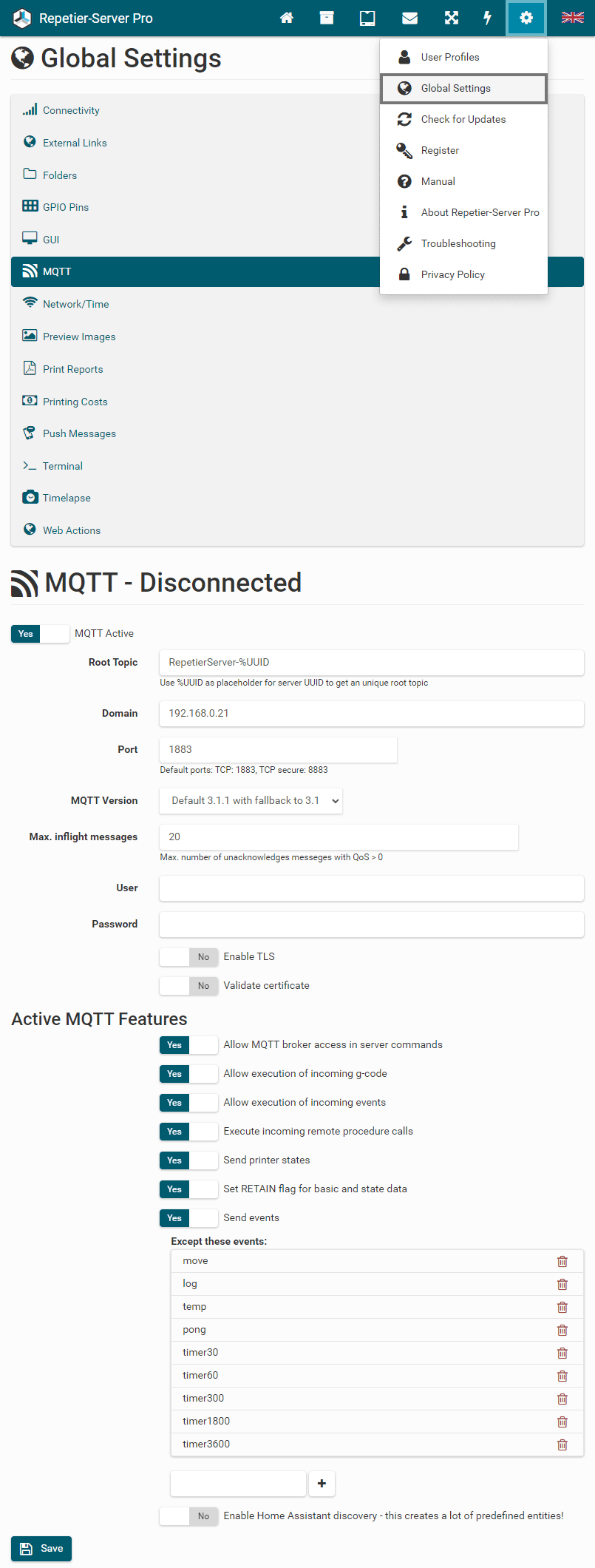

MQTT

MQTT = Message Queue Telemetry Transport is a standard in the world of internet of things. It allows an easy and standarized way to exchange messages and states. For example, you can connect Lafayette Rapid Prototyping Lab with a home automation or fabrication system. To achieve this, you must first connect to a MQTT broker.

First enter the connection data for the MQTT broker and save. If the MQTT Active button was on, the server will try to reconnect. On successfull connection the headline will switch to MQTT - Connected, in case of an error you will see an error message. Fix reason and save again until it connects.

If it works, you can set which data shall be sent and on which toppics we will execute received commands. You can send and receive messages with server commands if Allow MQTT broker access in server commands is enabled. For details on server commands see the MQTT chapter in server commands below.

To access Lafayette Rapid Prototyping Lab from third party software e.g. like Home Assistant, see here.

It is possible to catch all events triggered by Repetier-Server. Not all are of interest, and some are quite frequent, so in the MQTT settings, you can disable unwanted events to reduce traffic and load on clients. A default list with the most frequent unneeded events is prefilled on the first installation.

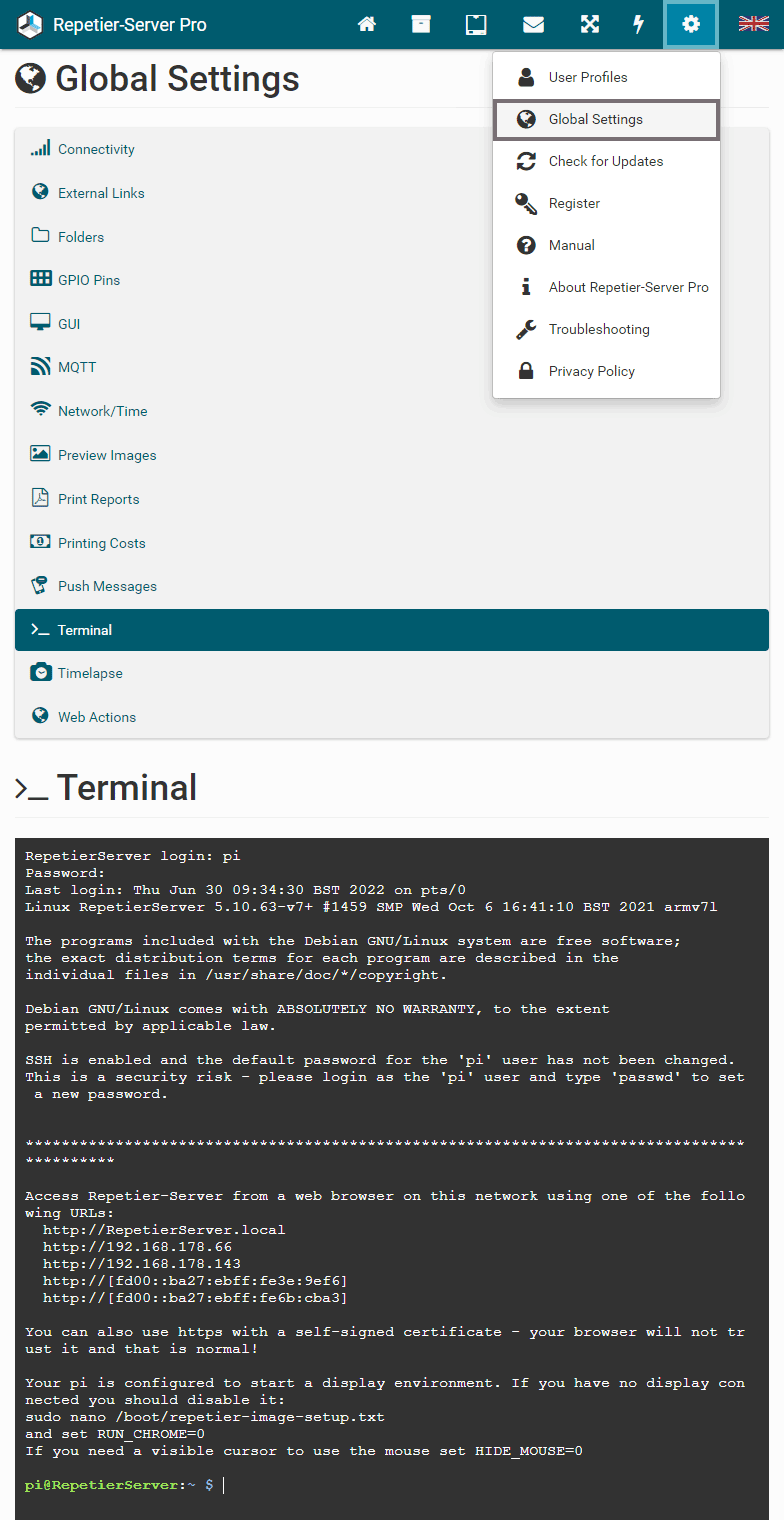

Terminal

If you run Lafayette Rapid Prototyping Lab on Linux or MacOS and you have configuration permission, you can get a full-blown command terminal inside our GUI. This way, no separate SSH connection is required to execute commands on the computer.

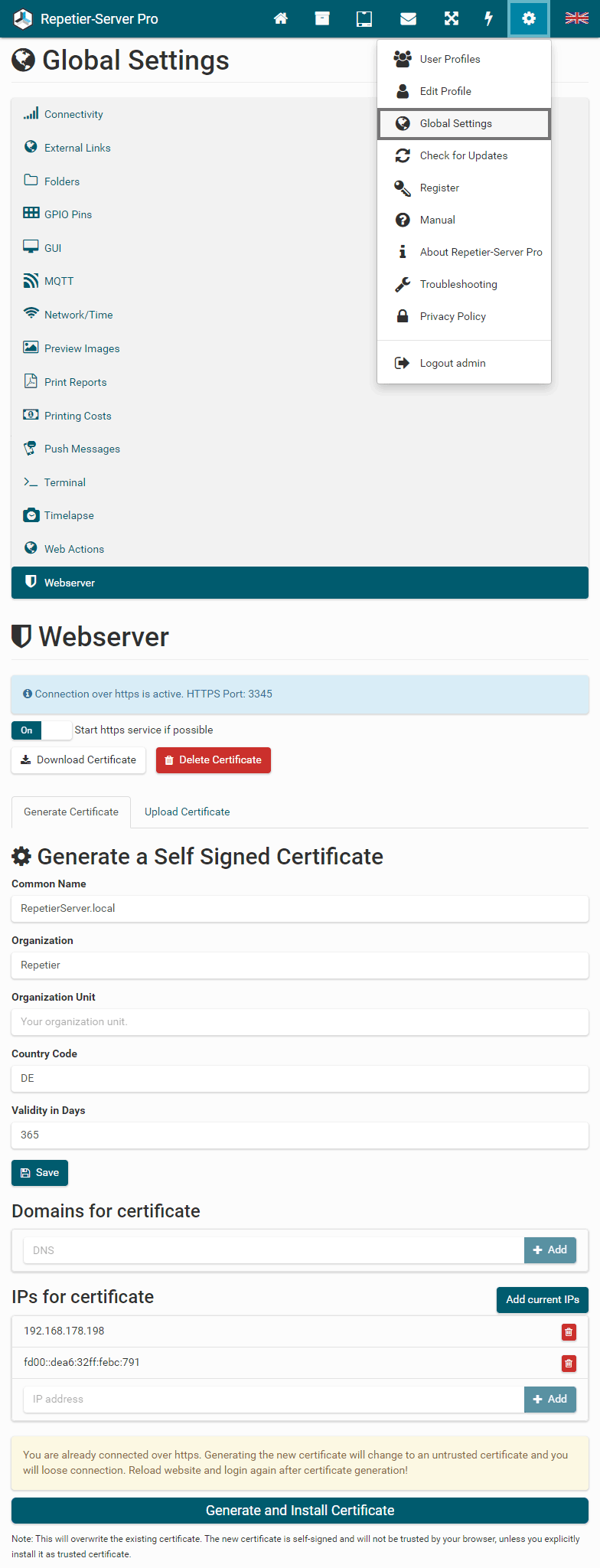

Webserver

For security reasons, we recommend using encrypted transmission so that you can access Lafayette Rapid Prototyping Lab via https://, especially if Lafayette Rapid Prototyping Lab is accessible from outside your network. You can use official certificates for this purpose, but you can also create your own certificate for free with a mouse click.

Self-created certificates are not signed by an official provider and are therefore not automatically verified by the browser, the browser will classify them as untrustworthy. You must therefore confirm that you trust the certificate to access the page.

If you do not want to go through this confirmation progress in your browser, you can add the self-generated certificate to the list of trusted certificates. This process differs depending on operating system, browser and browser version, so please search for your combination on the internet, e.g. with the search term "trust self-signed certificate windows chrome".

NOTE: You need to add the port for the secure connection as shown in the blue box - in our example the https port is 3345 e.g. https://ip-address:3345.

To create a self-signed certificate, enter your data and your country code. For the common name, use a domain name under which the server can be reached. Then click Save.

You can add alternative domain names and IP addresses to the certificate. If you click Add current IPs, it will use the IPs it has its own IPs in the network.

After that click Generate and Install Certificate to generate and install the certificate.

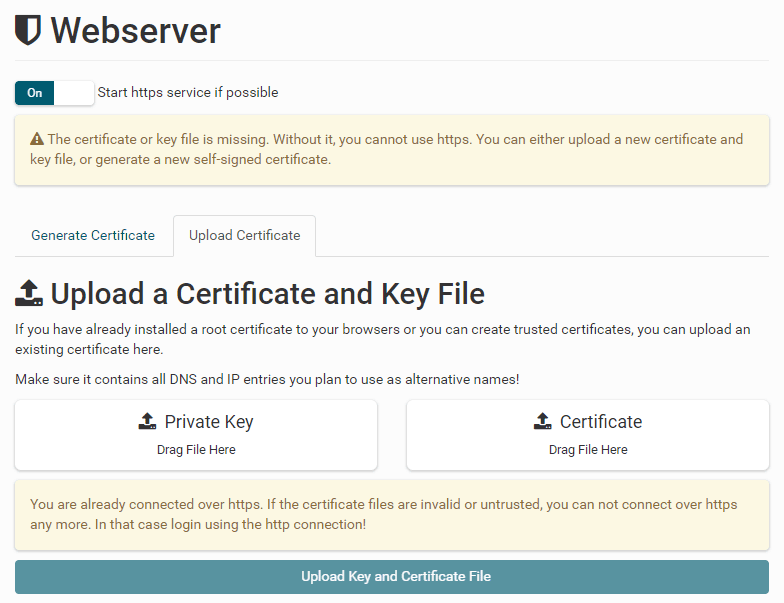

Alternatively, under the Upload Certificate tab, you can upload a private key and the certificate in PEM format you created earlier.

Why Adding a User

Lafayette Rapid Prototyping Lab has a user management to assign individual users specific legal rights. Anyone who uses Lafayette Rapid Prototyping Lab alone and only in the home network does not necessarily need a user management. But if you would like to have access to Lafayette Rapid Prototyping Lab over the internet from anywhere, you should definitely create a user account, otherwise hackers may have access to your server.

The first created user is a superuser with all rights. Then more users can be created with specialized rights, so that they e.g. can not change the printer settings.

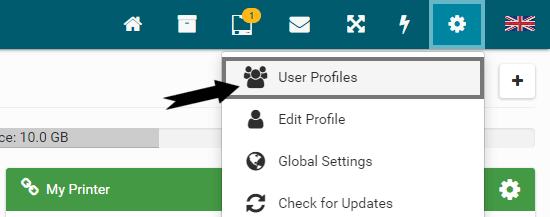

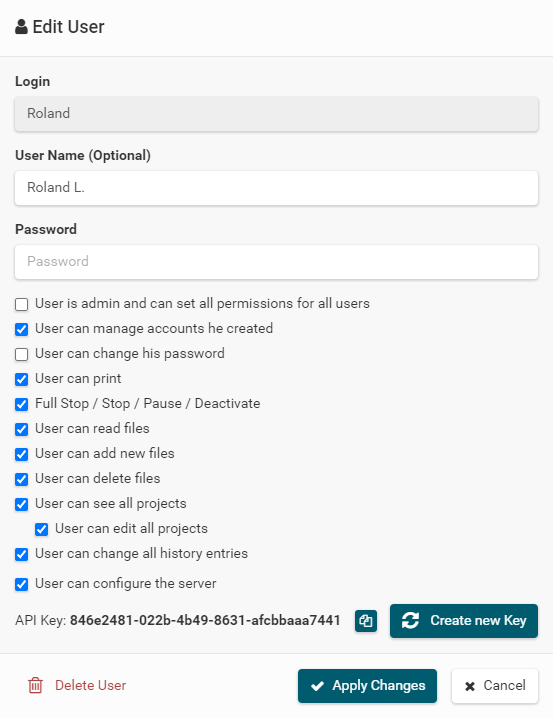

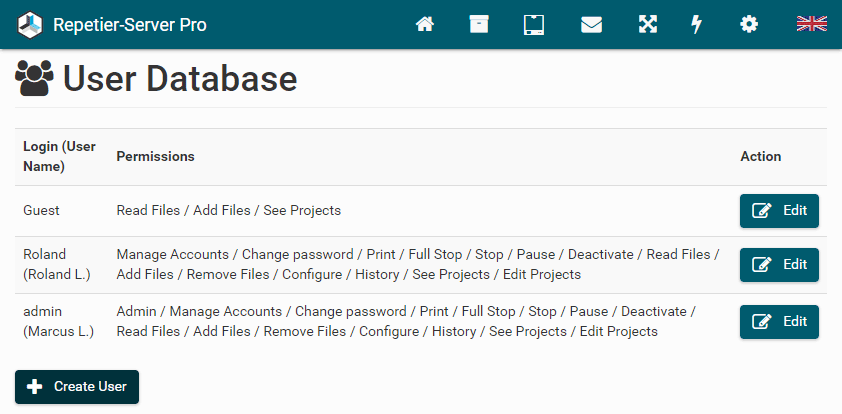

Add a User

Click at top right of the browser window on the gear and choose

User Profiles.

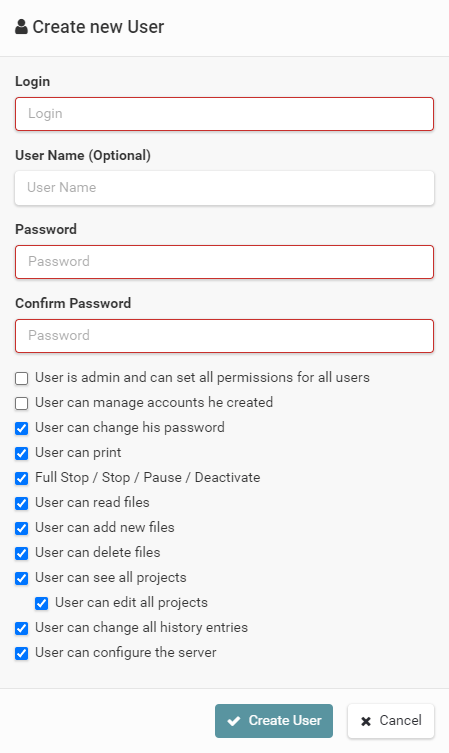

To add a new user click Create User. You just have to set a

login and a password, mark the wanted rights and click Create User. The user name is

optional and is only used for easier assignment.

The first created user is a superuser with all rights.

To add a new user click Create User. You just have to set a

login and a password, mark the wanted rights and click Create User. The user name is

optional and is only used for easier assignment.

The first created user is a superuser with all rights.

For the following users, you can decide which permissions they get. There are a few permissions that are special, so you need to understand them.

First of all is the admin permission. Admins always have all permissions, so all other boxes are checked automatically and disabled for change. Admin users are also the only users who can set any permission for other users and are the only user group that create users with manage account permission. With this permission you can add new users and assign them all of your own permissions, except the manage account permission. Last special admin privilege is using the terminal in global settings.

If a user with manage account permission and without admin permission gets deleted, the user will see a second question in case he has created any users. Since he can not control them anymore without his account, he can decide to delete them as well or to keep them. If they are kept, only the users them self and admins can delete these users.

Last important permission is the configure permission. With this the user can change

most configurations on a server and add/remove printers.

API Key

Every user has an API key. With this API key you can get access to the server with the selected rights.

This is used to add connectivity with other software without the use of login/password. Keep it secret

or change

it if you think it got compromised. To change the API key, click the

Edit button for the user and then click the button

Create new

Key.

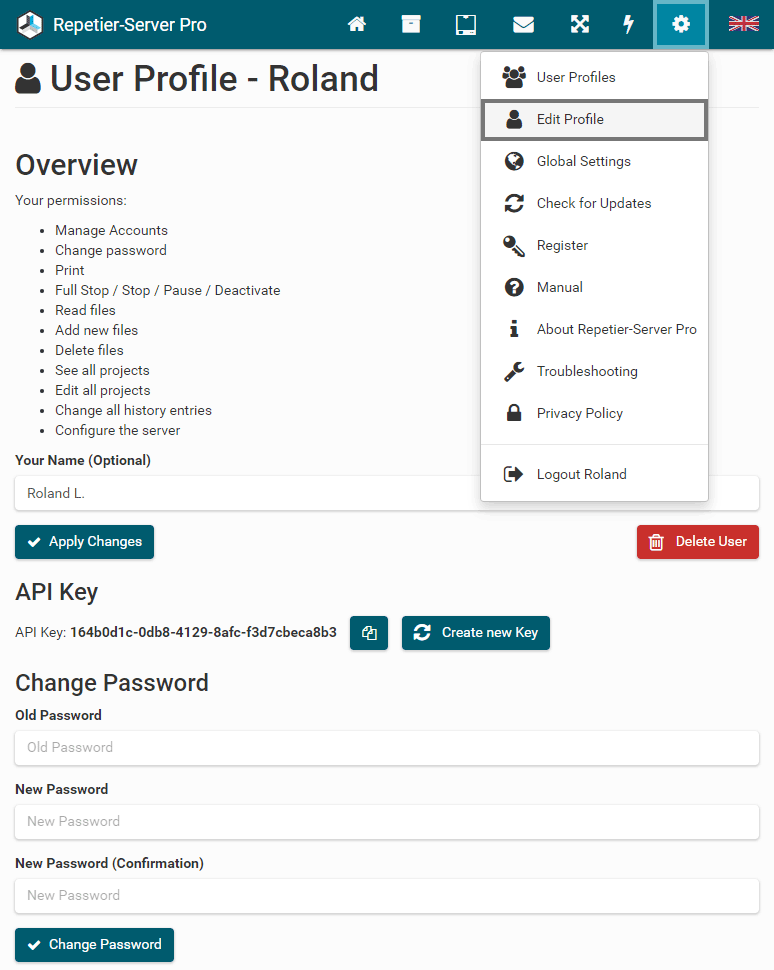

Edit Profile

Click at top right of the browser window on the gear and choose

Edit Profile.

Here you see all your permissions and you can change your name, your API key and your password.

And you can delete your account.

Here you see all your permissions and you can change your name, your API key and your password.

And you can delete your account.

Password Forgotten

If you have forgotten a user password, you can reset it if you have another user with configuration rights. As the last radical solution follow these steps:- Stop Lafayette Rapid Prototyping Lab (see installation)

- Delete the file storagedirectory/database/user.sql

- Start Lafayette Rapid Prototyping Lab

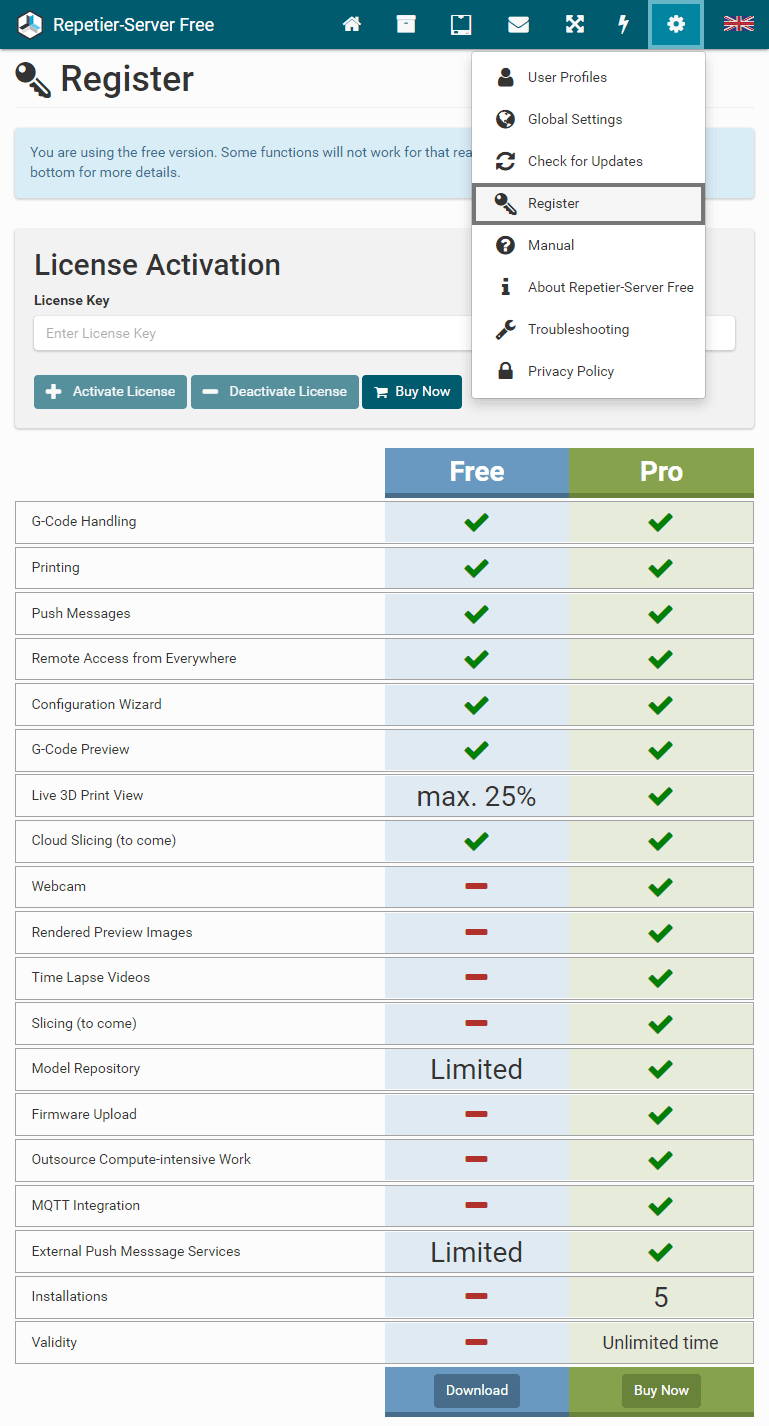

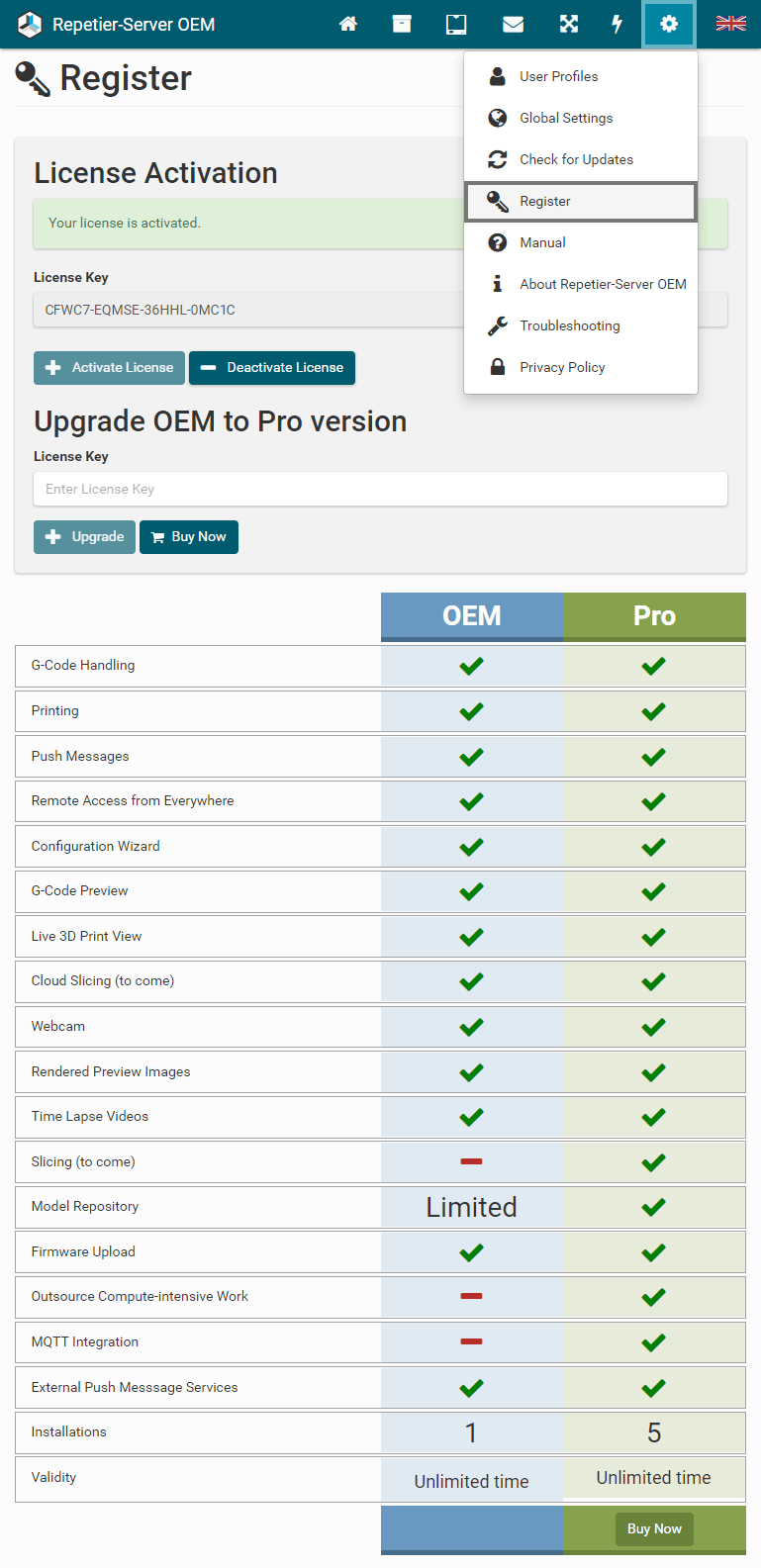

But there are some good reasons to upgrade now from the Free to Pro version:

- If you upgrade to the Pro version now, you can use the license key for 5 parallel installations.

- After expiration of the beta status, you can use all functions regularly.

- For updates, you automatically receive in the future all the new features.

- Your contribution helps the programmers to cover a part of the current development costs.

To upgrade Lafayette Rapid Prototyping Lab to Pro version, go to Register, enter your License Key and click Activate License. To activate the license key an internet connection must exist.

To deactivate an existing license key, click Deactivate License. To activate the license key an internet connection must exist. When the license is deactivated, the key will be stored and displayed in the license key field, so that you can activate it at any time easily.

Update Lafayette Rapid Prototyping Lab OEM to Lafayette Rapid Prototyping Lab Pro

If you bought your printer with an OEM version of this software, we offer a discount to upgrade to the Pro version. One OEM license can only be used on one computer. When you upgrade to the Pro version, you can use the new license for 5 installations to outsource computationally intensive work, and you get all functions.Here you can upgrade Lafayette Rapid Prototyping Lab OEM to Lafayette Rapid Prototyping Lab Pro.

Introduction

Now that you have your network ready Lafayette Rapid Prototyping Lab installed and you are familiar with it and like using it in your local intranet, you might wish to access it from everywhere to check out your prints.

This requires that there is a known route from your internet-connected device to your Lafayette Rapid Prototyping Lab instance. As long as you are using the server only in your intranet, it might be an option to not add any users. As soon as you open your server to the internet, you should forget that option. Create a user before doing so or everyone who finds the route through scanning will be able to use your 3d printer and do whatever they want, and you might not like that at all. So the minimum requirement is to have users with passwords. Then you might still have the problem that traffic is unencrypted, so a man in the middle could easily get access to it. But there are also secure solutions – it is up to you how secure it is.

Please understand that we can not provide further assistance on this subject since there are so many routers, internet providers and software solutions on the market. We do not know them and do not use them all, so we can not provide any help here. The basic problem you need to solve is how to publish an ip:port from your intranet to the internet.

Port forwarding

This is the easiest solution. You tell your router to map the port 3344 on the local ip xxx.xxx.xxx.xxx to any port you like. Then you can access the server from everywhere using http://your_router_ip:port

While this might work for many users, some will not succeed. The reason is then normally your internet provider who uses a protocol like DSLight which shares one external IP with different clients, so ports to the outside get mangled to something different, and you will not find the way in. In that case, this solution does not work.

If you have switching IP addresses, you might want to use a dynamic DNS hosting provider who maps your current IP to a static domain name. A free solution would be https://www.duckdns.org.

One thing to consider with this solution is that the data is not secure as you use the unencrypted http standard. If you want this more secure, you need a https->http proxy in your intranet that forwards to secure requests to the regular 3344 port. If you use our pi image, such a proxy is already available under port 443.

VPN

Using a virtual private network you get access to your complete intranet in a secure way including all Lafayette Rapid Prototyping Lab instances. You access them with the same IP as in your intranet – just remember to connect to your VPN first. Some routers provide VPN out of the box and there are many other VPN solutions. Since they all differ we can not provide additional help.

Forwarding service

There is another solution that we like to mention here, because it is the simplest one. A forwarding service starts a connection to the forwarding service, so they can exchange data. That service has a public url on the internet and request sent to that domain get forwarded. This does not require a port mapper or anything, just a script running on the computer running Lafayette Rapid Prototyping Lab. The easiest solution we found so far is https://ngrok.com. You can use the free account which is enough for private usage. The only real problem with the free account is that on every start of the ngrok client you will get a different domain name. The paid solution allows to always get the same domain.

Once you have the ngrok client installed and set up your account token as described on their homepage, you start it with

ngrok http 3344in your terminal window. You will then see two forwarding addresses – one for http and one for https. For security reasons, you should always choose the https version.

The only drawback of this solution is, that data gets sent from your pc to ngrok web server and from there to your browser. This increases latency and speed is also limited by the slowest component.

Other solutions

There are surely other possible solutions. One would be to make your own forwarding service if you own a web server in the internet. You could create a ssh tunnel to your web server and there use the web server to proxy the data to a subdomain of your choice. But this is an expert solution only for users familiar with networking, web server and proxy creation.

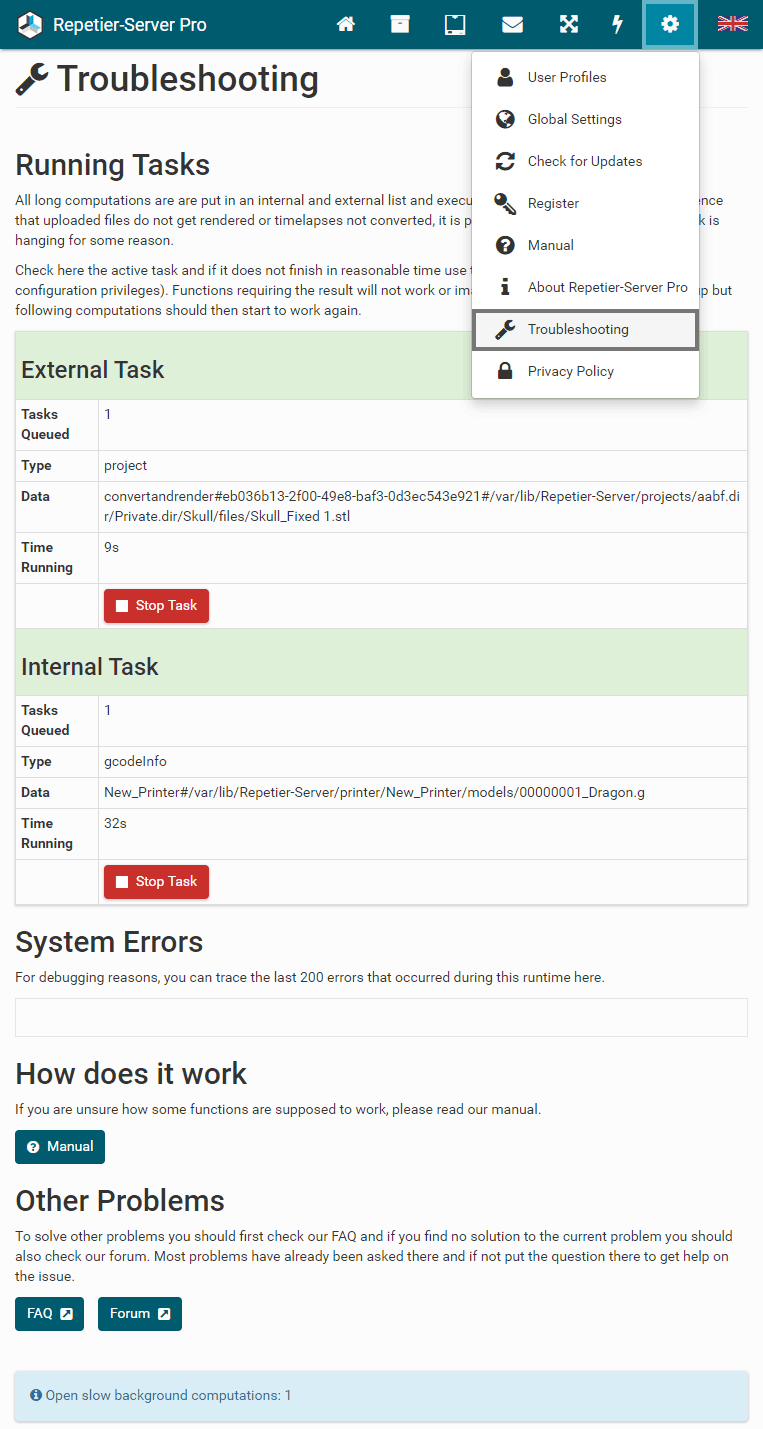

This page guides you to the best pages to solve problems. In addition, it will offer solutions to some

complicated

fixes that might be necessary.

Lafayette Rapid Prototyping Lab tries to not overload your computer. Therefore, all long computations are

queued

into two lists.

One handles calls to external programs and the other internally computed tasks.

With some files or settings it can happen, that a task never finishes, also this is only a very rare

case.

The fact that only one of these processes runs at a time, a blocking process means that all further

computations

will not happen.

As an indication you see the slow background computations do not decrease and new uploads do not get

rendered.

In this case you can stop the task using the Stop Task

button.

This will kill the running process and continue with the next one. As a result that file will never get

rendered, or

whatever the task was for will not finish.

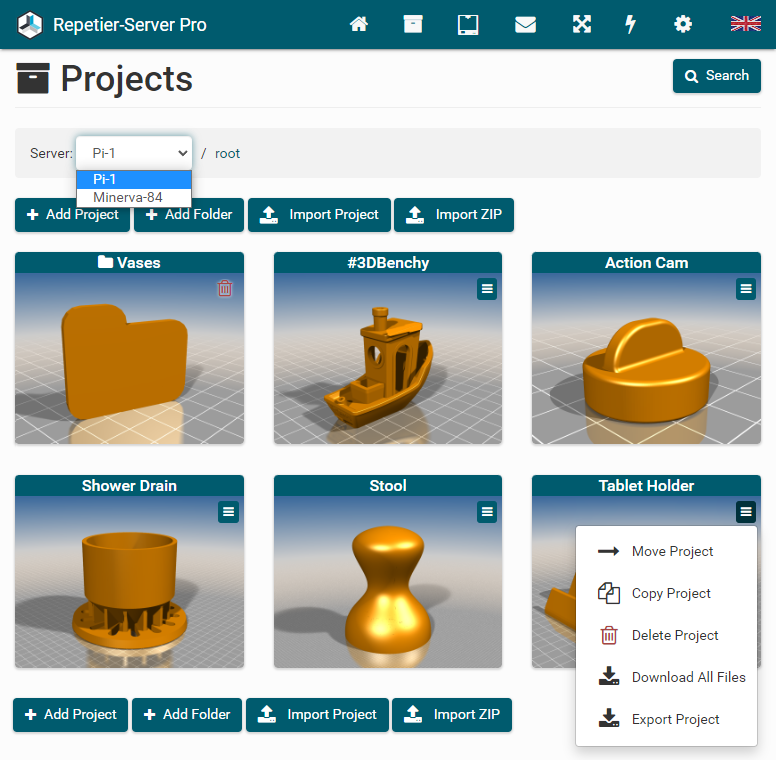

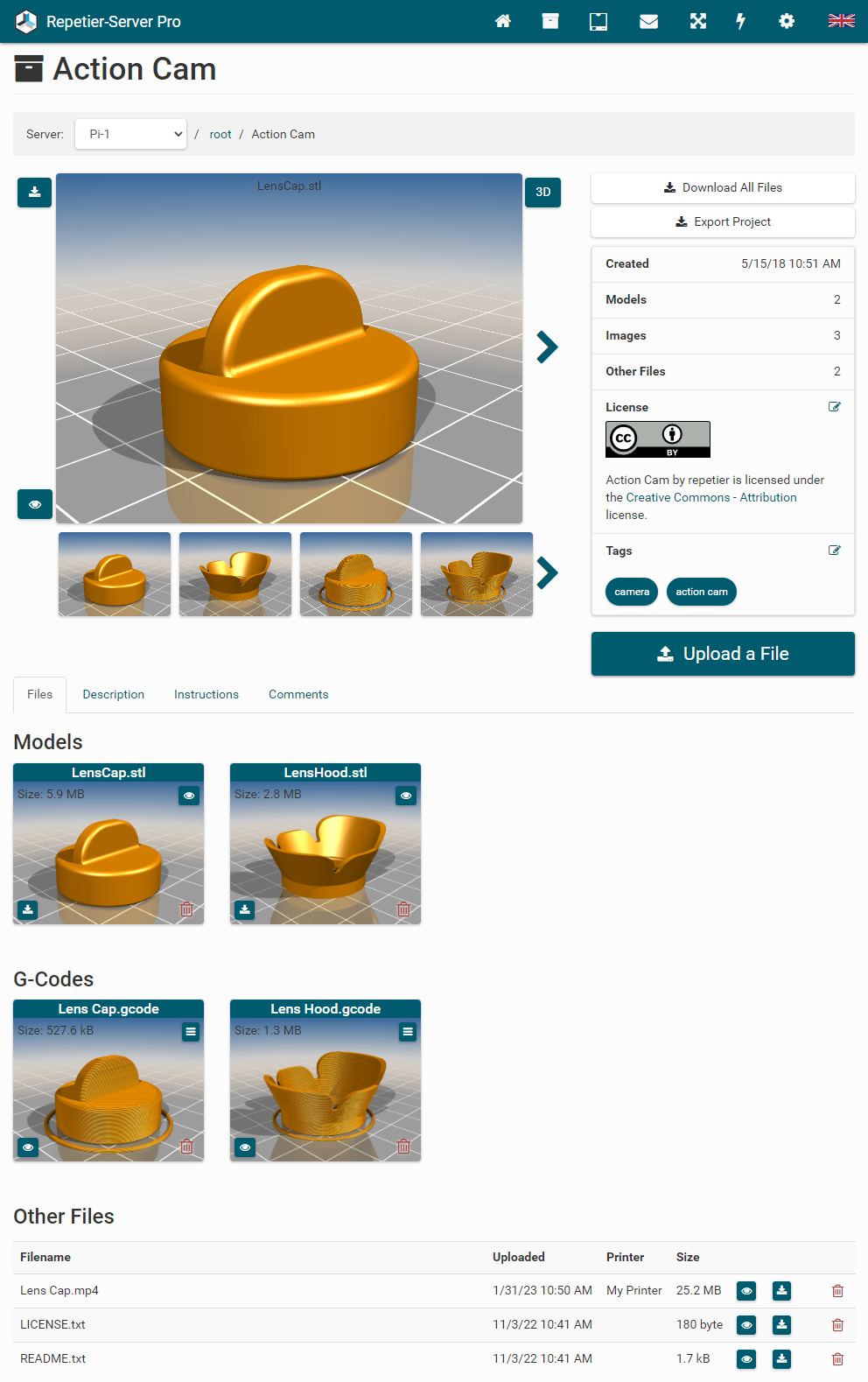

Printer Control

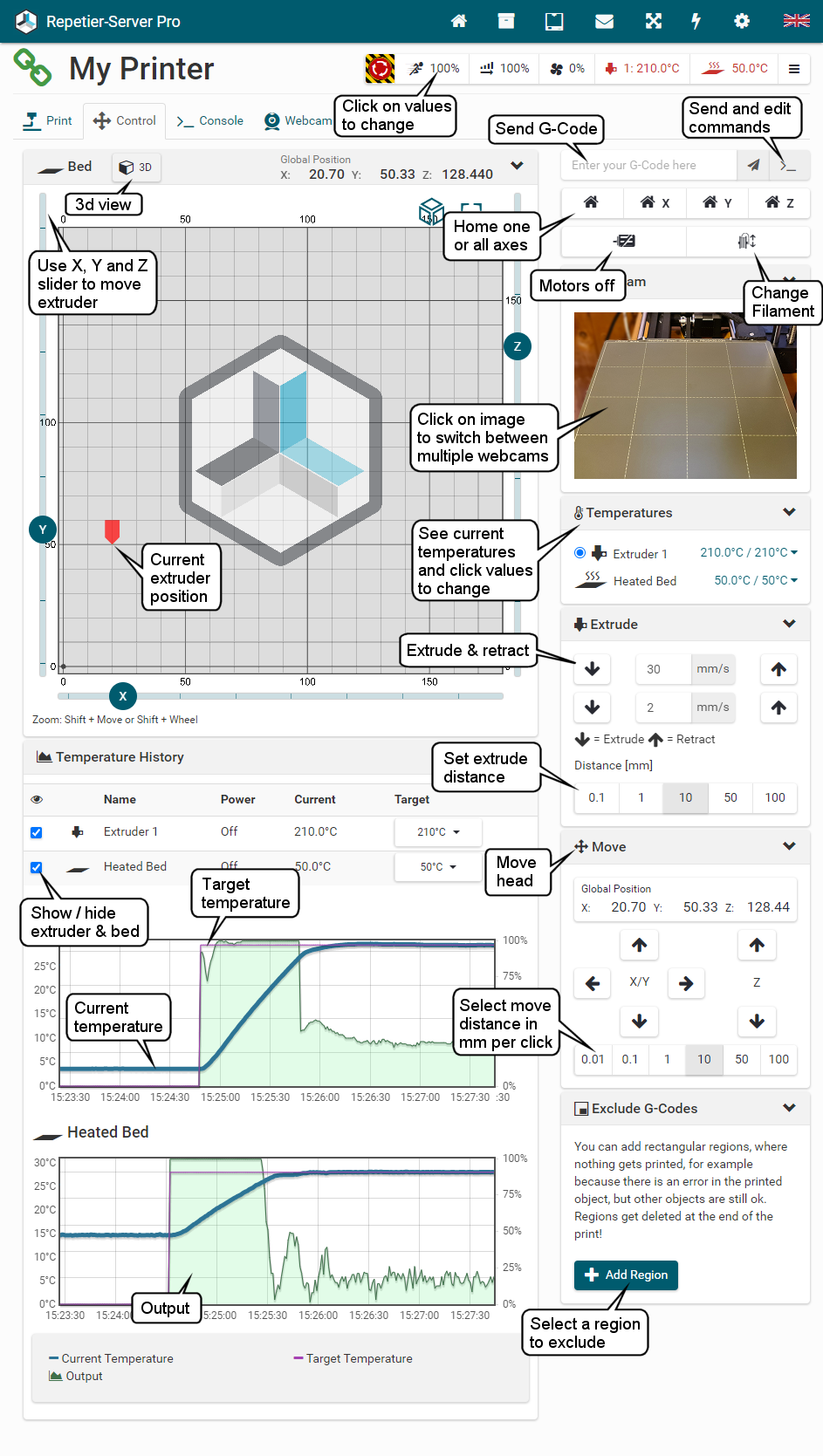

In the top navigation bar, you can access the following menu items:

- : Click here to go to the dashboard.

- : Click here to go to your projects.

- : Here you can switch between all printers. You also see the

current

printer status of all printers.

![]()

- : Here you get messages for special events like print finished or paused. You need to delete them in the menu by clicking the red button. In case of a paused message, the print will continue when you click on the red button.

- : Here you can switch between full screen and normal view in the browser.

- : Here you get to the main configurations, register the pro version, open the manual, and you can log out.

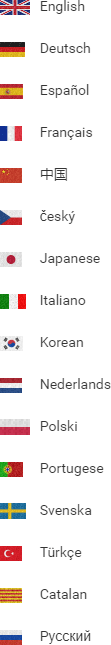

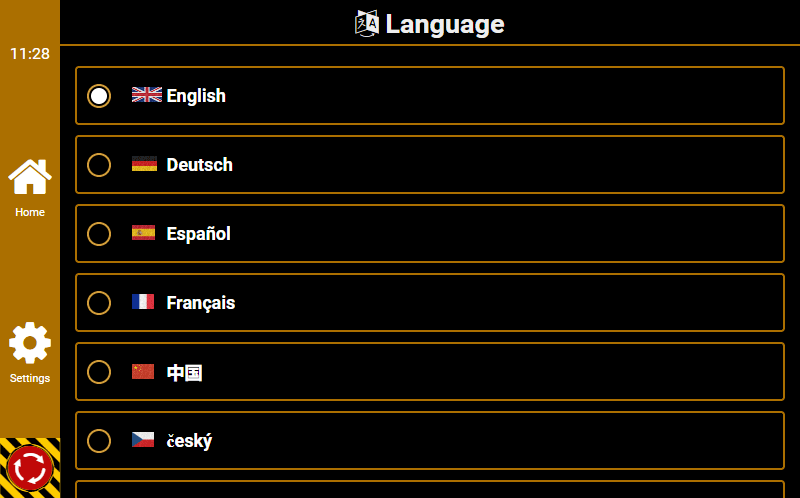

![]() : Here you can select your language.

: Here you can select your language.

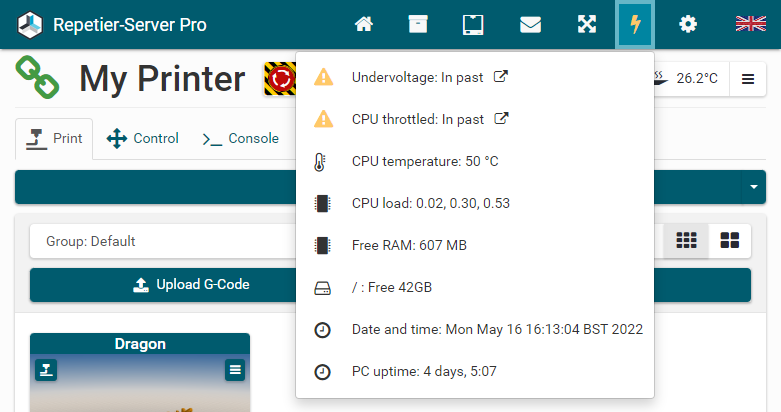

Extra icon for Linux

Cheap computers like Raspberry Pi and other embedded devices are very popular. These normally run under Linux and have limited resources. The icon is meant to monitor these resources and warn on possible problems early.

Under the icon the CPU load, the free RAM and the free disk space is displayed. The Raspberry Pi also displays the current or past undervoltages and CPU throttling and the CPU temperature. If there have been problems in the past, the icon is yellow, for current problems it is red. Undervoltage and CPU throttling can cause problems. If these occur, you will find help here to solve the problem.

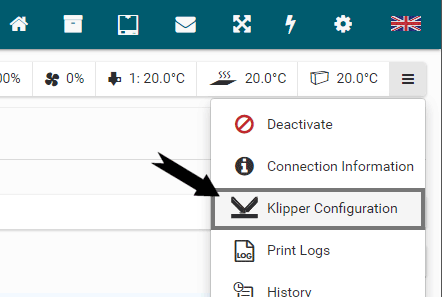

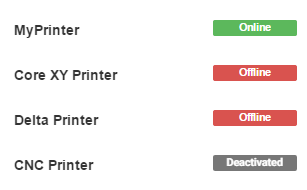

This is the starting point where you get a quick overview of all printer activities. For each printer you see:

- The color of the headline indicates the connection status (green = online, red = offline, grey = deactivated, orange = connected, but no communication).

- The menu allows you to Activate / Deactivate the printer, edit Printer Settings, Download Printer Settings or Replace Printer Settings and Remove Printer.

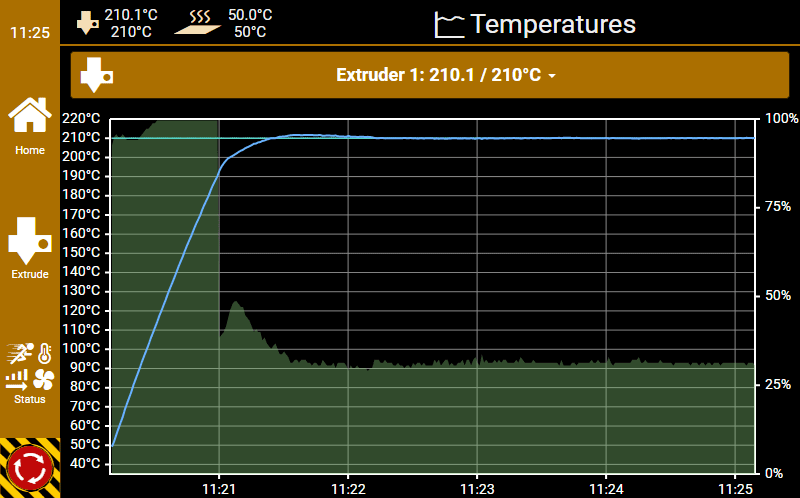

- The temperature graph shows the temperature of the current extruder.

- The progress bar shows the printing progress and job being processed.

- The Go to Printer button sends you directly to the printer control page.

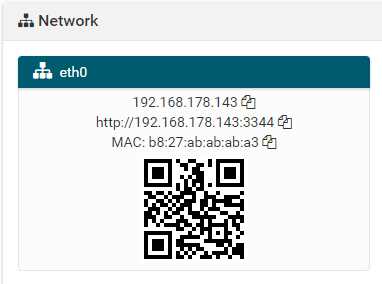

Under Network, you can see your IP address, MAC address and the URL to access the server with a different PC, smartphone or tablet. Also, you can scan the QR Code with a smartphone or tablet to open the URL.

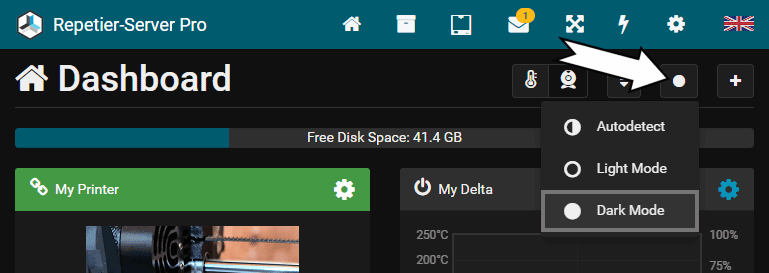

With the Dark Mode we have added a dark layout, that can be selected on the dashboard.

Click to change between Autodetect, Light Mode and Dark Mode. The setting is saved for the current user. If you select Autodetect, the light/dark theme set in the operating system will be used if your browser already supports this function.

Autodetect is supported from the following browser versions:

- Firefox 67

- Chrome 76

- Safari 12.1

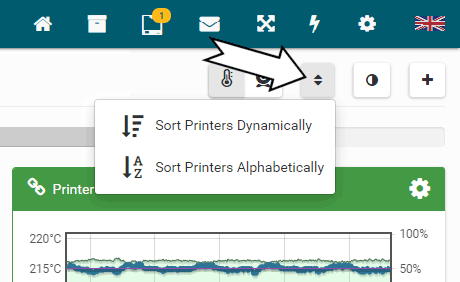

Click to sort your printer dynamically or alphabetically by Name.

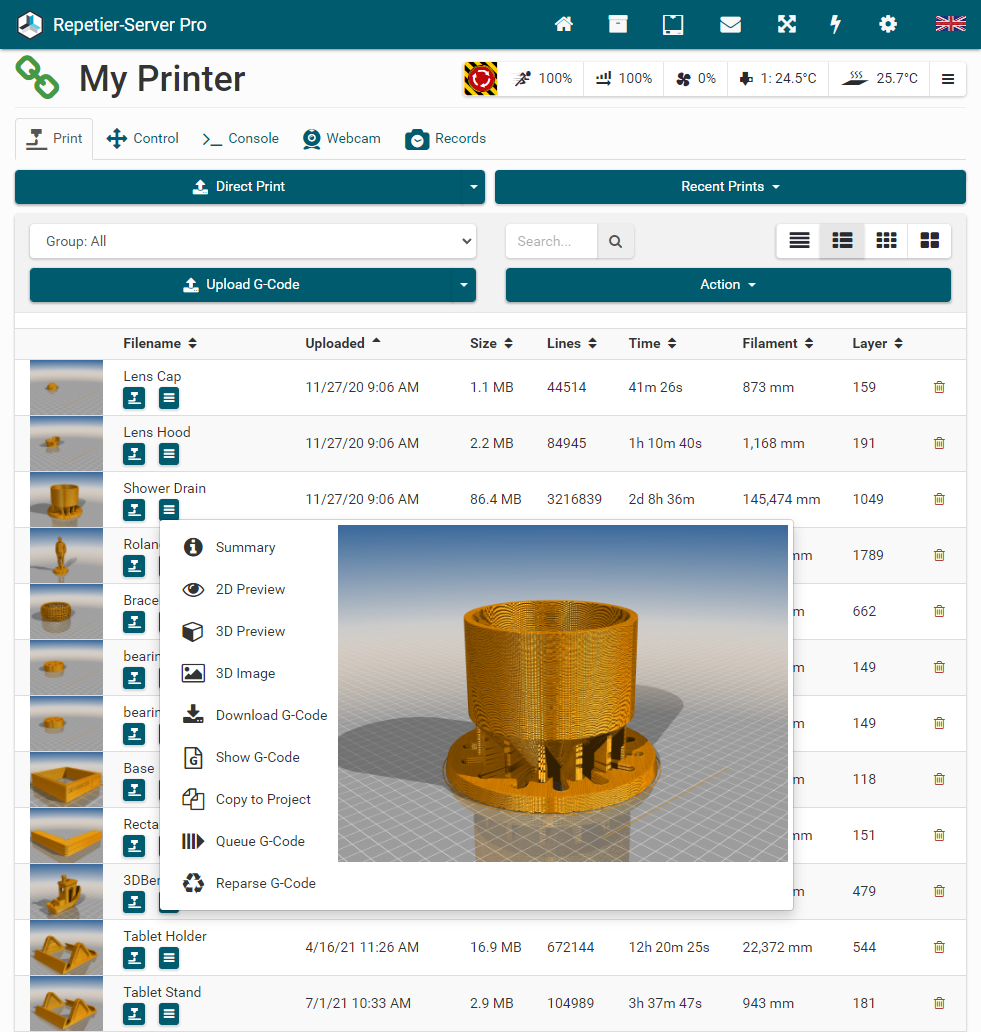

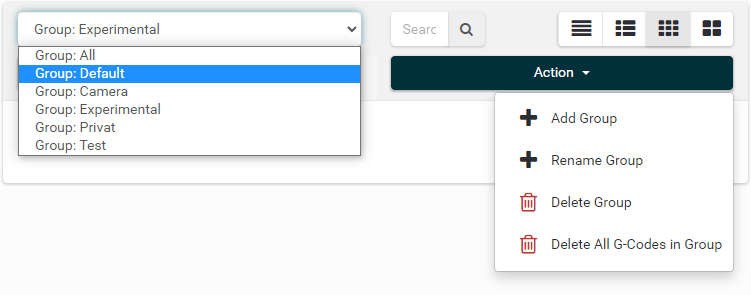

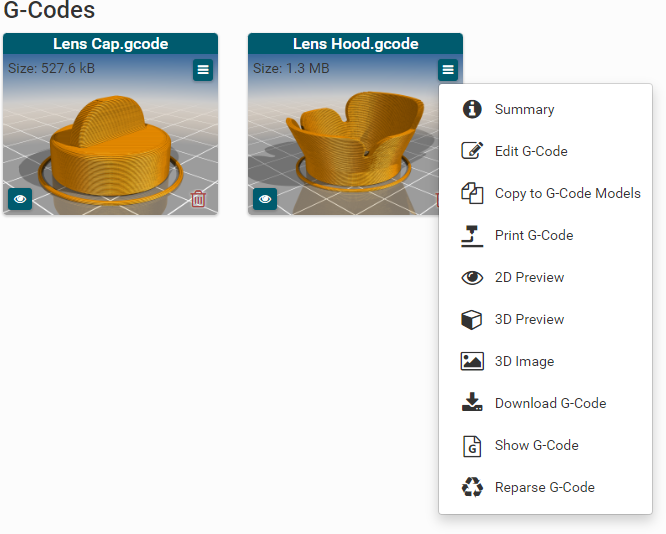

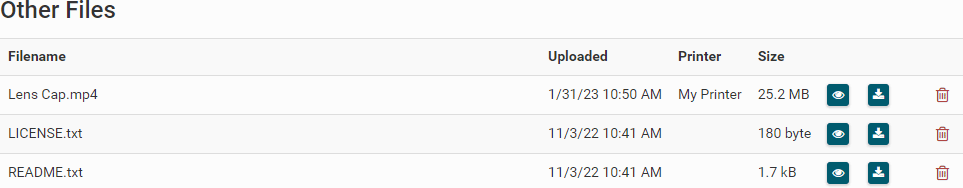

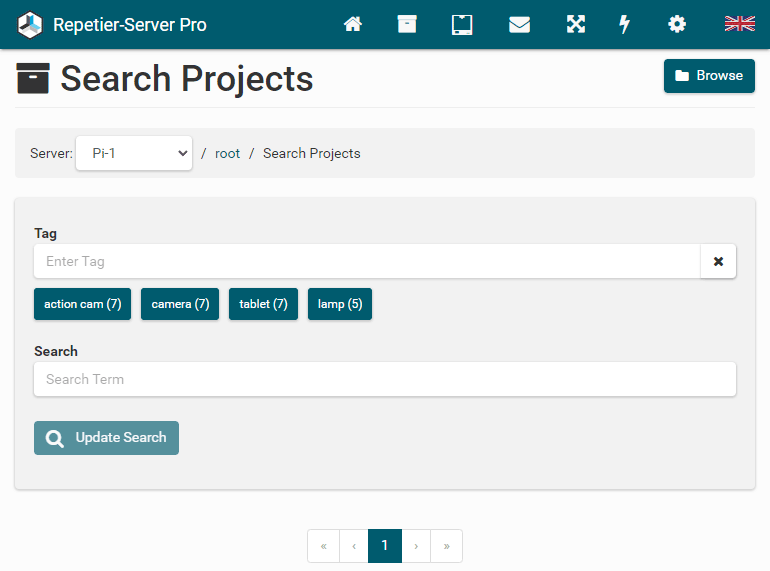

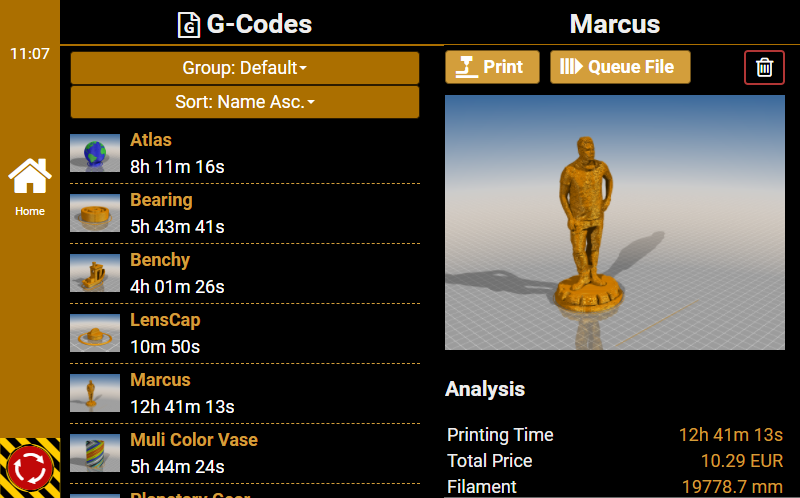

All G-Codes are stored in groups, so that related objects can be managed clearly in a separate group. If no group is assigned, the group DEFAULT is used automatically. Click Actions Add Group to create a new group and Delete Group to delete the selected group. If the group is not empty, you get a security question. Here you have to chose if the files shall be moved to default group or if the fields in this group shall get deleted.

Important: All imported files get stored in the selected group. If the current group is ALL, it will be stored in the DEFAULT group.

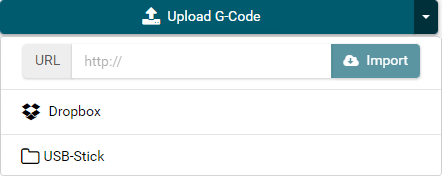

To upload new G-Codes click the Upload G-Code button. To upload and start printing directly, use the Direct Print button.

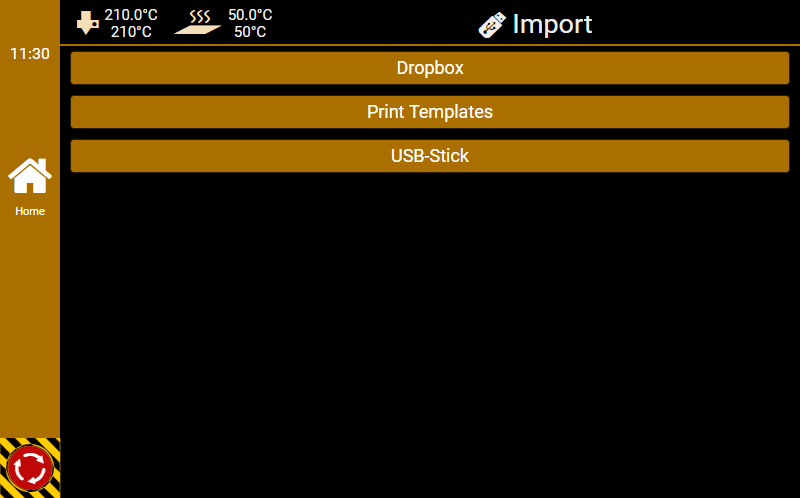

Click on the right side of the Upload G-Code button to open the dropdown menu. Here you have three more options to import G-Codes:

- Enter an URL to download and import a G-Code from the internet.

- Click Dropbox to open your Dropbox online account. This fields only appears, if the domain is localhost or 127.0.0.1. If you are not online, this field will not also appear. If not already done, you have to log in with your Dropbox access data. The selected files will get downloaded and imported.

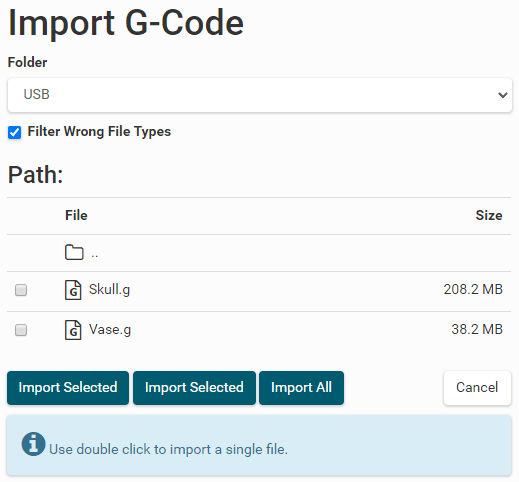

- If you have defined folders in Global

Settings

Folders, they are displayed here. Click on the folder to browse through the folder

content.

![]()

Here you can import multiple G-Codes. Use double click to import a single file.

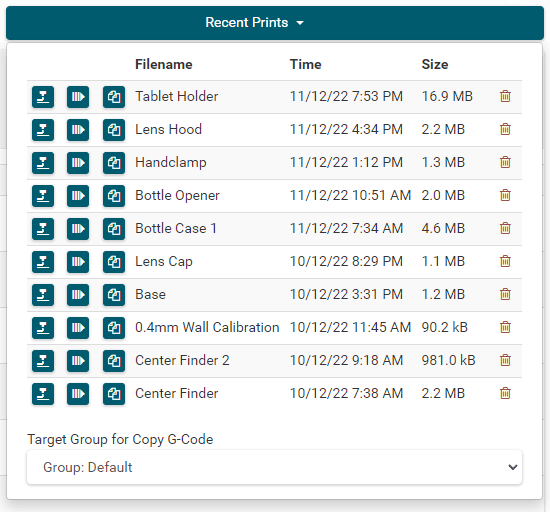

Click Last Prints to see the last 10 prints. They are stored here even if you used Direct Print. You can print the g-code again or copy it to the group selected at the bottom of this card.

The search box allows you to search by file name in the selected group. The results are automatically displayed as you type.

Here you can select the display types of your G-Codes:

G-Code information without images

G-Code information with small images

256 pixel wide images without G-Code information

512 pixel wide images without G-Code information

By clicking a heading in list view you can sort all entries ascending or descending.

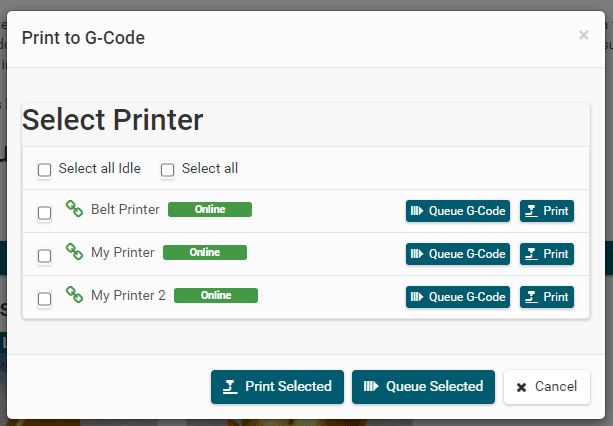

Click to start printing. If a job is already running, this will add the job to the print queue.

Click to delete the object.

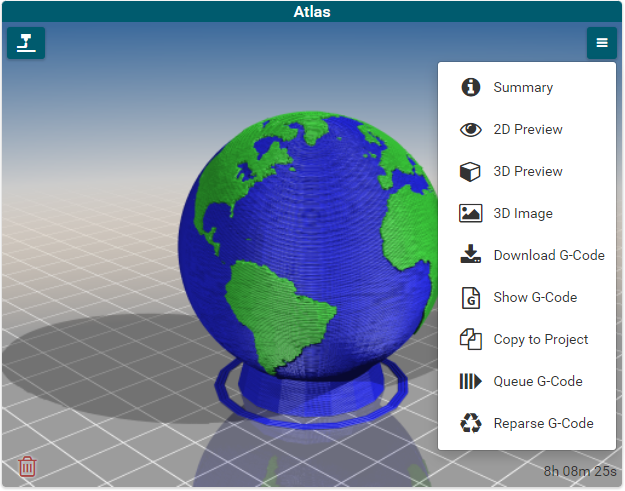

Click 2D Preview to get a 2D Preview.

Click 3D Preview to get a 3D Preview.

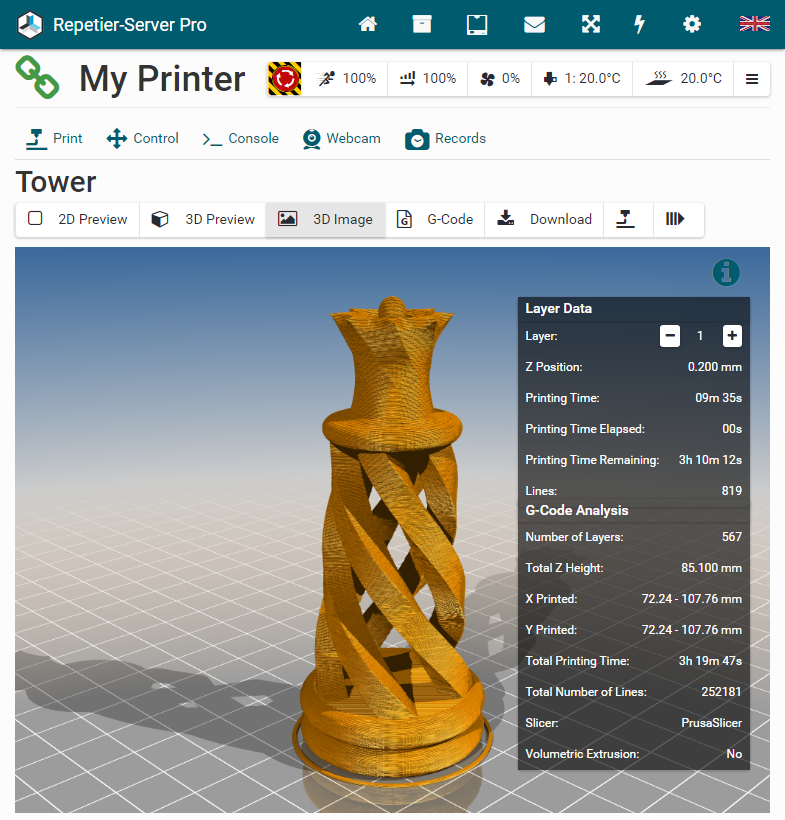

Click 3D Image to see a detailed rendered 3D Image.

Click Download G-Code to download the G-Code.

Click Show G-Code to show G-Code.

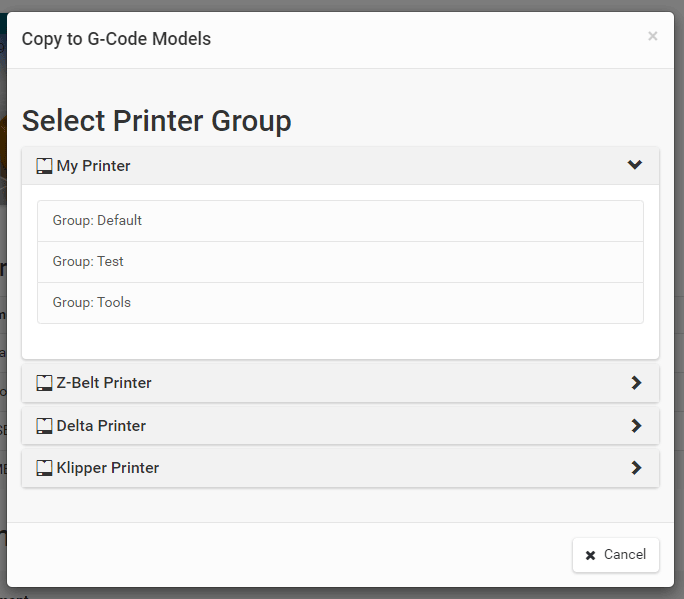

Click Copy to Project to copy the G-Code to an existing project. The printer to which the G-Code belongs is displayed in the project. The G-Code can also be sent from the project to other printers.

Click Queue G-Code this will add the G-Code to the printing queue and not start printing directly.

Click Reparse G-Code reparses the G-Code with the current printer configuration. This can lead to different printing times.

Click Summary to get detailed information including price calculation:

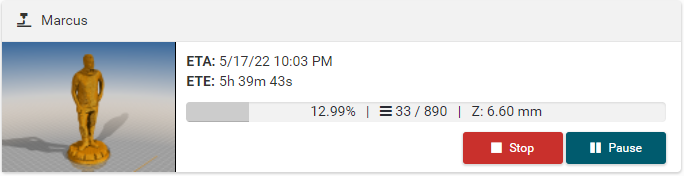

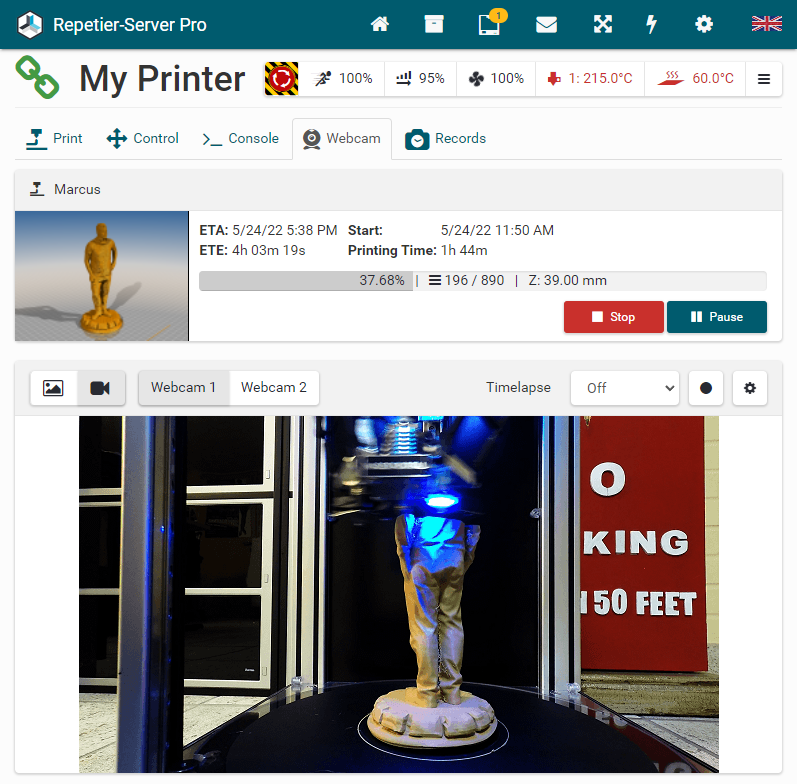

When a job is running, you see a progress bar with ETA (Estimated Time of Arrival) and ETE (Estimated Time En route) and you can pause or stop the job.

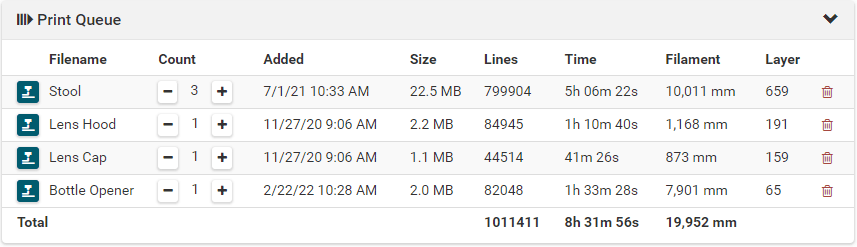

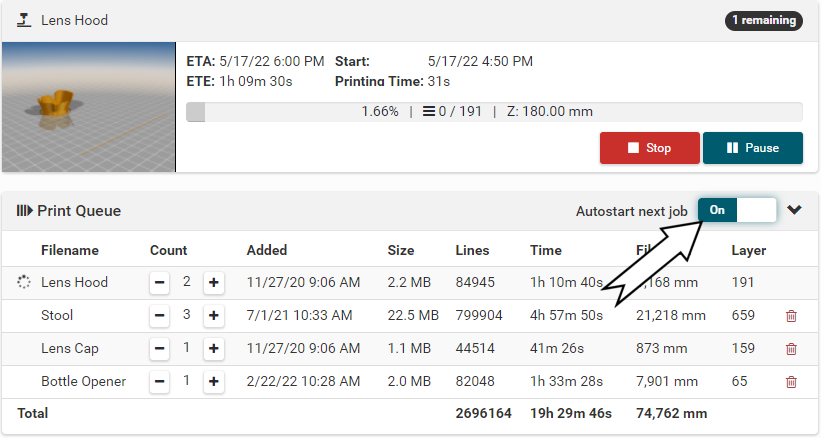

If you start more than one job, you get a print queue. You can also put prints directly in your queue. After a job is finished, you can start the next job by clicking . Under Count you can set the number of prints. You can also change the print order by drag & drop the prints. This is especially useful for belt printers, as it allows you to specify the number and order and to start the next print automatically by setting Autostart next job to on. If several objects are printed from the queue, the number of prints remaining after the current print is displayed in the upper right corner.

2D Preview

Here you can check and visualize your G-Code before you print. In 2D Preview you always see the currently selected single layer. That way we can visualize even very big G-Codes, which normally would not fit into RAM. The server also only downloads the currently viewed layer to minimize traffic. When you click on G-Code, you will see the selected layer directly. Click i to print the object directly or click to queue it.

Here you should check in the first layer whether the model lies well on the print bed so that it does not come off during printing.

With

you can slide through the layers or use

you can slide through the layers or use

for

exact layer navigation.

for

exact layer navigation.

With

you see the move order for this layer.

you see the move order for this layer.

With

you can set the

color scheme (Extruder, Feature Type, Speed, Width and Height) and what you want so be displayd. Click

Default Preview to safe the current settings as default.

you can set the

color scheme (Extruder, Feature Type, Speed, Width and Height) and what you want so be displayd. Click

Default Preview to safe the current settings as default.

With

you can select the zoom level to fit printer or

fit object.

you can select the zoom level to fit printer or

fit object.

With

you get layer data g-code analysis with object

size,

printing time, ...

you get layer data g-code analysis with object

size,

printing time, ...

With

you can switch to the full screen view.

you can switch to the full screen view.

With

or Esc you can leave the full screen view

again.

or Esc you can leave the full screen view

again.

Click Download to download the G-Code.

3D Preview

Click 3D Preview to see the g-code in 3d. Here you can examine the model in 3d very effectively with different color schemes and thus detect any errors before printing and avoid misprints.With the two sliders on the right, you can hide the areas at the top and bottom completely or make them transparent. You can also show and hide movements, retractions, skirt, support and infill.

Important: Depending on the file size, it may not be possible to display the model because the browser cannot provide ENOUGH ram. To prevent the browser from crashing, you can set and save a warning for a max file size together with your preferred view as default. These settings are stored in the browser and not in the database. Since PCs can usually display much larger files than smartphones, you can set this separately for each device. If the displayed file is too large, the browser crashes. Don't worry, Lafayette Rapid Prototyping Lab continues to run regularly. If the browser crashes, go back one page in the browsing history and reload the page.

3D Image

Click 3D Image to see a rendered image of the model.

G-Code

When you click on G-Code you see the complete G-Code of the current layer. You can navigate through the layers by clicking + and - in Layer Data blog. To switch back to preview click 2D Preview.

To edit the G-Code, click on the line number you want to edit. The editor will pop up and show you the selected line. You can choose to remove the line and/or add new G-Code before that line. To edit the selected line, click Original G-Code. This will copy the line and select delete original line. This is useful if the command is correct, and you want to change parameters. Pause is adding a pause command.

After closing, you will see the changes in the G-Code. You need to press Save G-Code to save this permanently. These changes do not modify the original file. Instead, you edit a patch file. For this reason you should limit yourself to small changes. Saving the changes will trigger a recalculation of printing time.

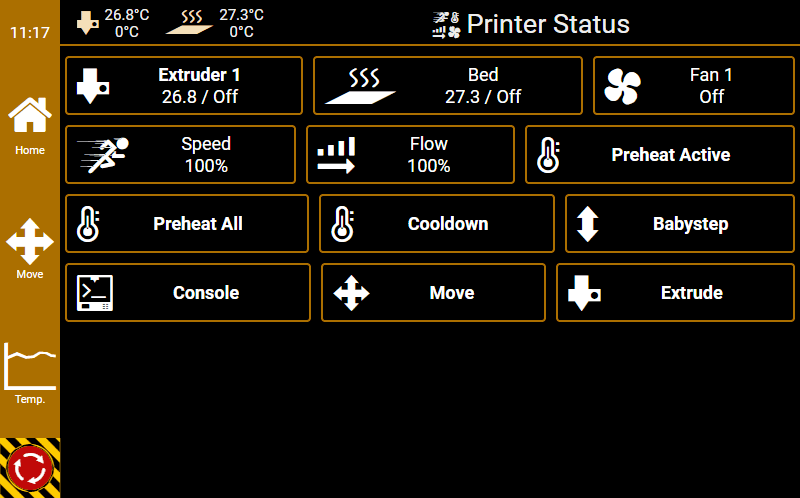

You find these basic controls on all printer pages ( Print, Control, Console, Webcam and Records):

If you click on the respective button, the corresponding control panel will open.

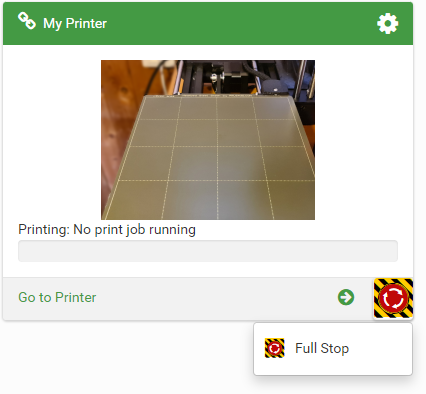

Emergency Stop

In the case of an emergency, a hardware reset is the best and quickest solution. If the printer does not have a reset button, or you are not near your printer, you can use our emergency stop button . This will send a M112 command to your printer. The command is not processed until the buffer is empty, it may therefore take a few seconds to affect. For M112 different actions can be set in the firmware. Please test in advance what happens when you click .

Speed

You can quickly change the speed with the round slider or by clicking on the number in the middle. The speed is relative to the G-Code speed, so 100 means original speed and 150 means 50% faster than planned. Changing the speed will not change the calculated times correctly. If you have changed your speed, you do not have to change the flow. Increasing speed may reduce the print quality.

Flow

You can quickly change the flow with the round slider or by clicking on the number in the middle. The flow changes the amount of extruded filament. If you see that you get not enough extrusion, you can increase the value. If you see filament piling up to high you should reduce it. Ideally your slicer should contain the right flow multiplier, so that you always print with 100%. If you change the speed, you do not have to change the flow.

Fan

You can quickly change the fan speed with the round slider or by clicking on the number in the middle. If you are printing, the G-Code may contain fan controlling commands which can overwrite your settings. Below the slider you can switch the fan power on and off without changing the value.

Extruder

You can quickly change the temperature of the current extruder with the round

slider or by

clicking on the number in the middle.

If you have defined temperature values in your printer settings, they get displayed below, so that

you can

click them directly.

To set these predefined values go to

Printer Settings

Extruder

Predefined Extruder Temperatures.

Heated Bed

You can quickly change the bed temperature with the round slider or by clicking on

the

number in the middle.

If you have defined temperature values in your printer settings, they get displayed below, so that

you can

click them directly.

To set these predefined values go to

Printer Settings

Extruder

Predefined Bed Temperatures.

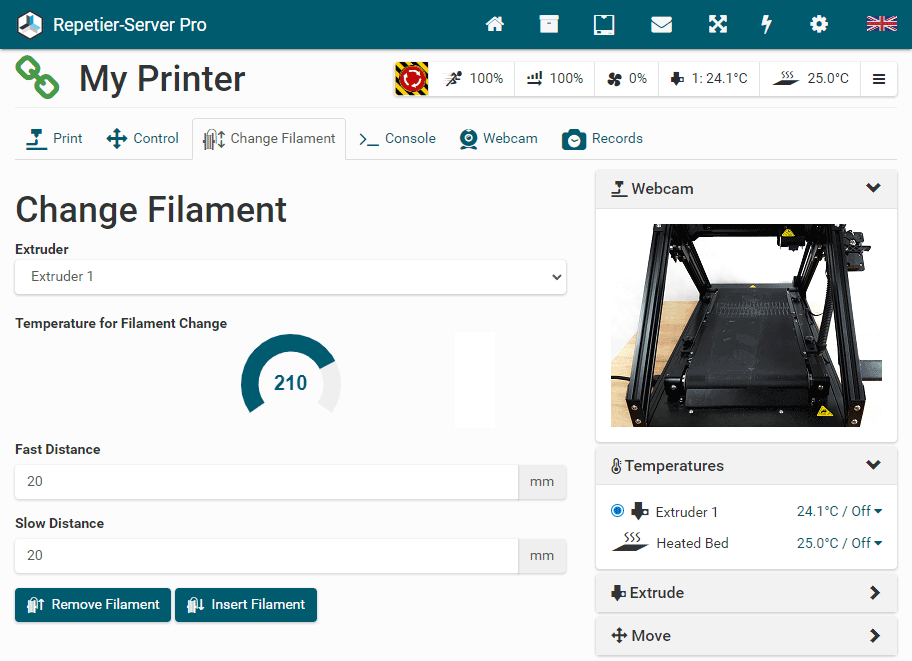

Change Filament

With this function it is easy to change your filament.

- Extruder: Select the desired extruder.

- Temperature for Filament Change: Set the temperature for the filament used. The temperature of the last print is always suggested.

- Fast Distance: If you insert filament, this distance will move first with the retraction speed set for the extruder.

- Slow Distance: If you insert filament, this distance will move with extrude speed set for the extruder. In case of filament removal, this will also remove fast.

- Click Remove Filament to remove the filament or Insert Filament.

- After selecting Remove Filament or Insert Filament you see info with the temperature. Click Finished to cancel heating. When heating is finished, the insert/remove procedure starts. In case of insert, you have to click the Start button, so you have time to insert the filament. Afterward you can insert or remove more filament in 10 mm steps if needed.

Exclude G-Codes

If you are printing several objects in parallel, it can happen, that one object fails, or you just do not need all objects. For this case you can add rectangular regions, where nothing gets printed. Click Add Region to add a rectangle on the print bed while pressing the left mouse button. You can add multiple regions. Each region gets a separate color and is listed with this color in the Exclude G-Codes list, so you can find and delete the corresponding region easily.

You can add new regions anytime before or during print. They take effect immediately after adding. After a print job is finished, all regions get deleted.

If you exclude g-code during print in 3d view, you will get a top view of the final print, so that you can easily exlude the correct rectangle. For precise drawing, the cursor is marked with a crosshair on the print bed.

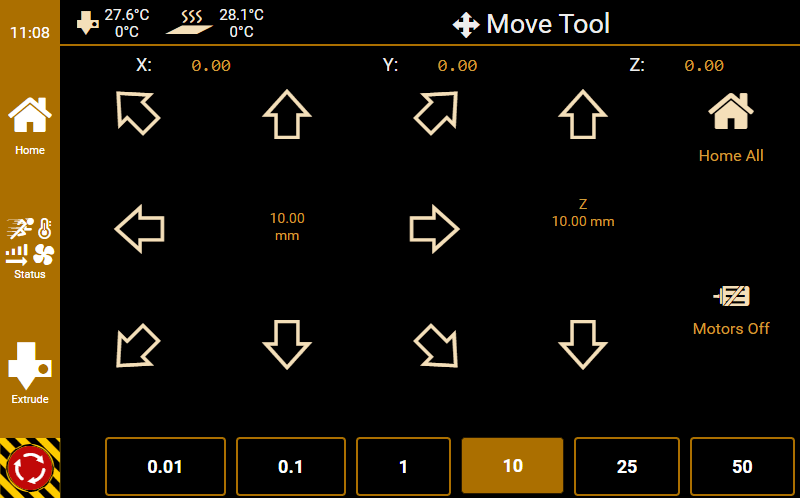

On this page you can control and visualize your printer. If you are not printing, you also see three sliders which you can use to move your head. Make sure you have homed before you do this!

On this page you find these additional controls:

Click 3D to switch to 3d view.

Click 2D to switch to 2d view.

Zooms to fit the complete bed.

Here

you can set the quality and what should be

displayed, like the whole model with the not yet printed part in transparent. Click

Default Preview to safe the current settings as default.

you can set the quality and what should be

displayed, like the whole model with the not yet printed part in transparent. Click

Default Preview to safe the current settings as default.

With

you can select the view and the zoom level

to fit printer or fit object.

you can select the view and the zoom level

to fit printer or fit object.

With

you get a g-code analysis.

you get a g-code analysis.

With

you can switch to the full screen view.

you can switch to the full screen view.

With

or Esc you can leave the full screen view

again.

or Esc you can leave the full screen view

again.

ACK filters background handshake which is normally of no interest.

If Commands is enabled, you will see all commands send to the printer.

The Pause Log switch pauses logging until disabled. This allows you to scroll through the last stored lines.

Enable Filter M105 to hide the temperature output.

Below the switches comes the command input. Enter your g-code and enter Return or click Send to submit your g-code. If you click on a g-code in the output field, it will be copied into the input field.

You can start all wizards using the Wizardsstrong> button. These are of course not available when printing.

The Commands menu allows you to send predefined scripts to the firmware.

Hint: If you need to send a non g-code command, e.g. for firmwares accepting shell commands you need to prepend a # char to the line. In that case, the line will be sent 1:1.

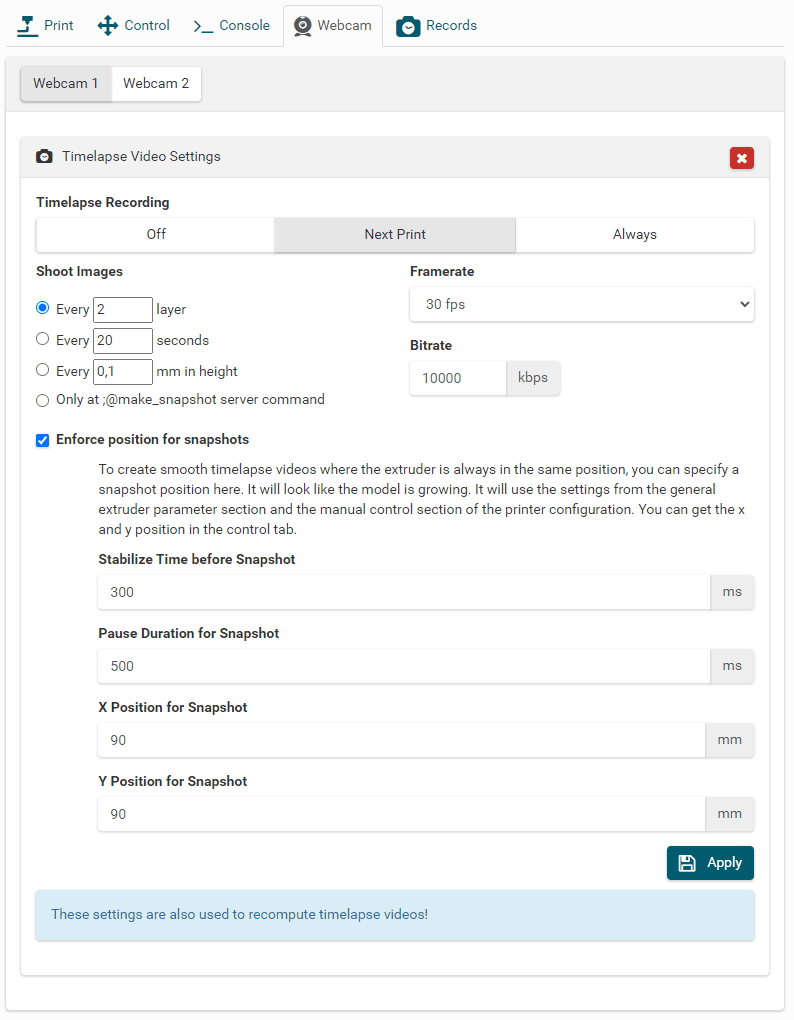

For each webcam you can set separate timelapse settings. You can set the timelapse record to off, next print and always. If you have already started a print and you want to record a timelapse video afterwards, click . Click to configure your timelapse video settings.

Timelapse Video Settings

Another really cool feature is our timelapse function. To use this you have to set the Static Image URL for your printer in Printer Settings Webcam (see configurations for Windows, Linux and Mac). You also can set the orientation of your webcam ( ), so that it gets displayed correctly.

Here you see the Timelapse Video Settings for your printer. Each webcam has its own settings and you can record from multiple webcams at the same time.

You can set Timelapse Recording to Off (no images get stored), Next Print (only for the next print images get stored) or Always (images get always stored). While capturing the

image is

displayed on the webcam video.

image is

displayed on the webcam video.

Under Shoot Images you can set how often an image shall be saved. You can save pictures every x layer, seconds or mm in height. Notice: Every x layer will not work if you print in vase mode.

If you have entered the path to FFMPEG in Global Settings Timelapse, you can define a Framerate and a Bitrate for the generated mp4 video. If you did not install FFMPEG, you can still record images and view them like a video with our image player. The higher the bitrate, the better the video quality, but it also makes the videos larger.

To get smooth timelapse videos, you can specify an extruder position for the photo. Depending on the webcam, it may be necessary to specify a stabilization time before or after the snapshot so that the extruder does not move when you take the picture and it moves quite smoothly later in the video.

And one more tip: Watch your lighting, especially for prints that go for a very long time. Constant lighting conditions are best, daylight is distracting for long prints because it always gets so dark at night.

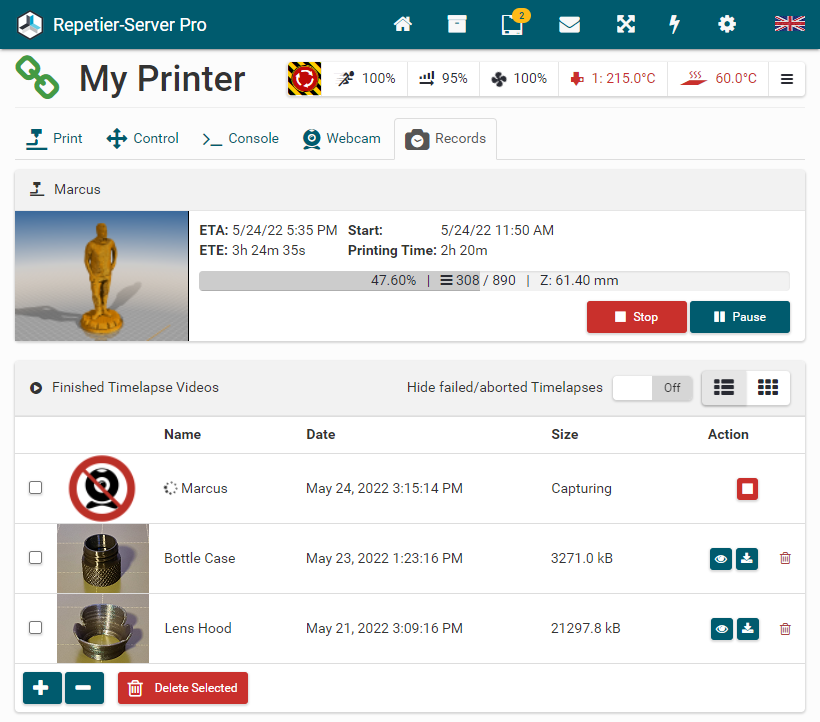

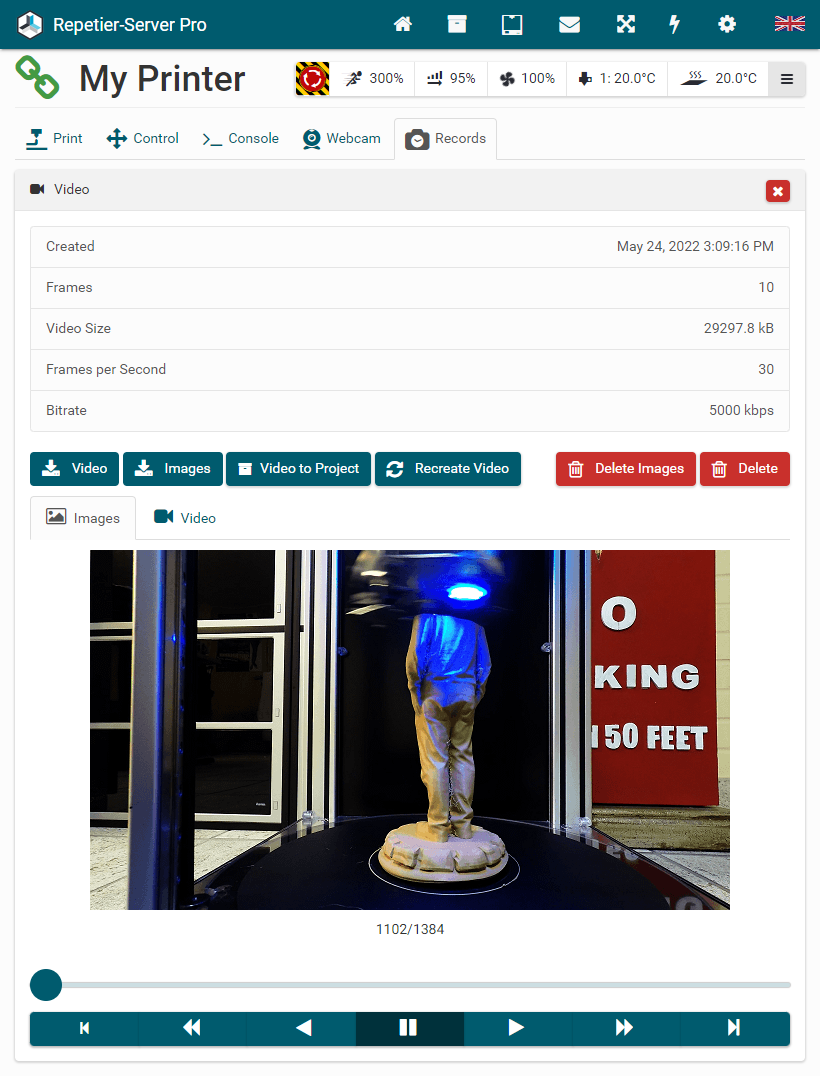

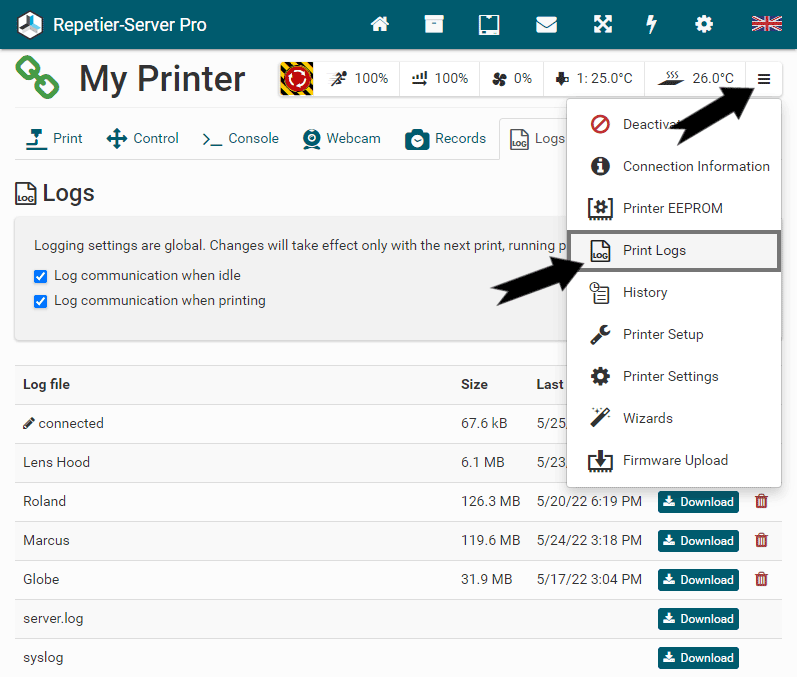

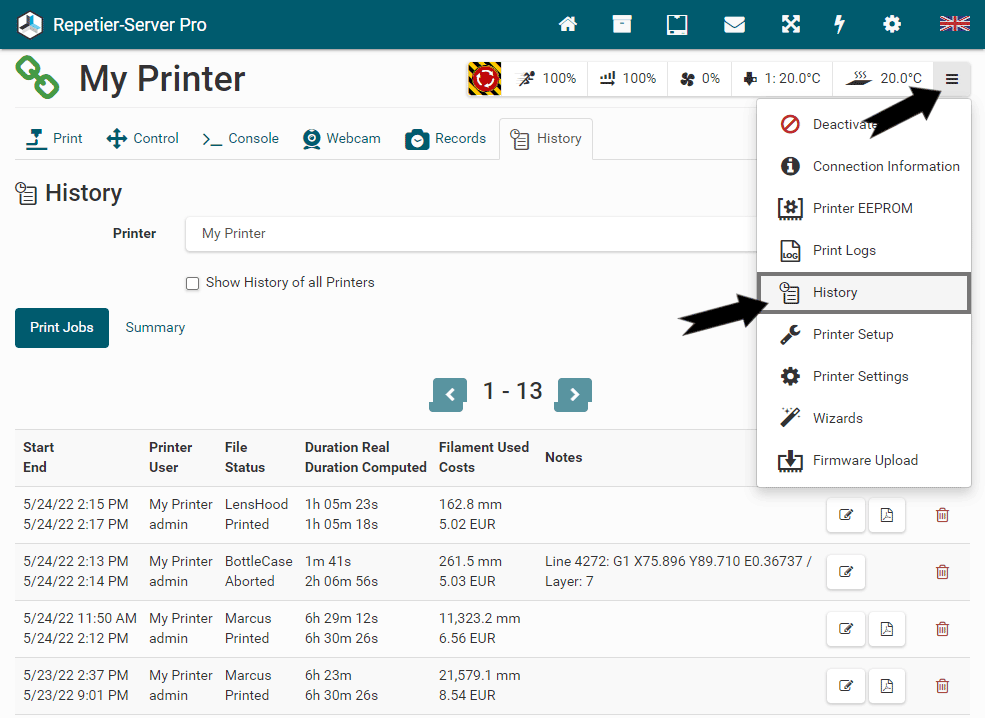

Records

To view, download or delete existing records, click Records .

Here you see all captured timelapse videos, images and the current capturing.

View video, images and details

Download mp4 video

Delete images and videos

Stop running record

To delete multiple videos, you can select them and click Delete Selected. Use to select all and to deselect all.

Video

If you click in Records you will see some details and the image video player below.

Click Video to download the mp4 video and Images to download all captured jpg images in a zip file. Use Video to Project to copy the mp4 video to an existing project. If you want to render the video with new bitrate and/or framerate settings again, click Recreate Video. Delete Images will delete only all images. Delete will delete the video and all images.

Below you see the image video player, where you can scroll through using the buttons:

Stops playback

Plays the video at normal speed

Plays the video quickly

Plays the video backwards quickly

Shows at pause the next image

Shows at pause the previous image

With Images and Video you can switch between image and video player.

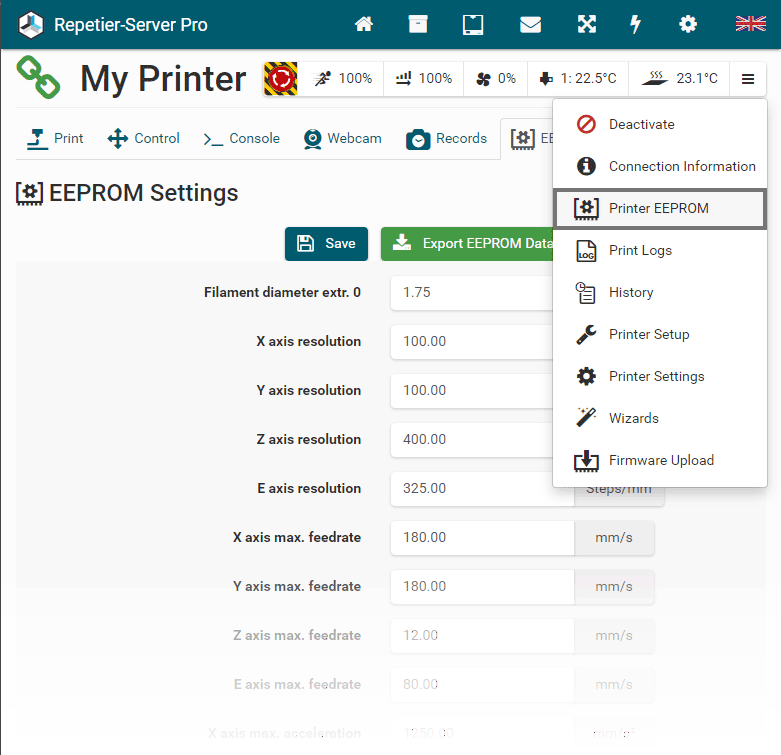

Changed values are marked in green, as long as they have not been saved. Incorrectly entered values he will be marked red. Click Save to save changes.

If you want to change some values, you should export and save your current eeprom settings. Click Export EEPROM Data to save the current settings as .epr file. If you want to load saved settings into the editor, click Import EEPROM Data. The loaded settings that match position and type of the viewed settings will be replaced by the loaded values. To store them into eeprom, click Save.

Lafayette Rapid Prototyping Lab has a rescue system, that can help you to continue prints that were

aborted due

to connection or power loss. Before you enable this feature in

Printer Settings

you need

to understand how this works and how it can be improved.

When the rescue system is enabled and you start a print, it will write an additional file with the

extension

.recover, which contains lines send and acknowledged. If a connection is lost it will also mark the

exact

position and close the file. A bit more difficult is the case of power loss. If printer looses power

the

server will most likely also loose power, so it can not flush and close the file safely. So the last

lines

send

might be missing, and it also depends on the os ability to recover the file. With some luck the

firmware

has a power loss detection and can inform the server. If you have told Lafayette Rapid Prototyping Lab

what the

firmware sends on power loss, it will also as fast as possible flush and store the file. If the PSU

last long

enough, this means we have the last lines saved and restarting is easier. After server is up you will

see the

reason for failure. If we were fast enough you will see power loss, otherwise unknown reason.

In any case you will see in the web frontend a message that the print failed, and you can go to the

rescue

page. Meanwhile, the server will try to reconnect, enable heated bed and chamber (if configured to do

so)

and run a recover connection script. The script is just an entry point to help to increase the

likelihood of

recovering the print. For example if z moves easily it might be a good idea to enable motors to

prevent z

axis from moving and hence losing the position. On the other side if you home to z max that makes

it easy

to get the right position after failure.

To continue the print, you have to tell from which point to continue. If the firmware supports the

host

rescue protocol we might get the last printer position from the firmware, and you can not choose. In

all

other cases you see the g-code around the time of failure. You can mark last acknowledged and last

send

line with a Select button or click in the g-code listing on the left side to mark a

different line. Then

make

sure everything is as needed to continue and hit Continue

Print.

This will replay the

g-code to the marked position internally and only send some state changing commands to firmware.

Once the

position to continue is reached the process script gets executed and then the normal print will

continue.

The script

will be called after the last temperatures are set, except if the script contains the command

@waitForAllTemperatures,

in that case your own script has to define where to wait and with which tolerance.

Typical actions and problems to think about

- Your printer homes to z-min. This means after reconnect z is unknown by the printer. So you must guess the right z height and hope z does not change until you continue. Enable z motor as soon as possible. Lafayette Rapid Prototyping Lab will send a G92 Zxx to set the Z position.

- Your printer moves to z-max. You can add a home to z max in your connection or process script. That ensures the correct z position when you continue.

- Firmware supports the HOST_RESCUE capability. In that case firmware will store last send position and move the extruder out of the print area. After reconnect it will know the position to continue and also knows the own position. This even allows automatic continue after a failure.